Replace the split-ring style bearing (6) and

guide rod O-ring(s) (15B) into I.D. groove(s)

in each piston (3). Install O-Rings (15C) onto

pistons.

For size 05 actuators, install O-rings (15C)

onto the pistons.

14.2.4 Replace O-ring (15E) and bearing (15H)

(10–42 sizes only) on the bottom of shaft. On

the top of the shaft add the two stainless steel

washers (10–35 sizes only) with the thrust

bearing (10) between them. NOTE: On later

models only a single stainless steel washer

is used and thrust bearing (10) is not used.

Locate the top bearing (15G) and O-ring (15D)

into the body. Insert the shaft through the

larger opening in the bottom of the body.

14.2.5 Replace the stainless steel washer over the

top shaft extension.

14.2.6 For sizes 10–50, very carefully align the piston

guide rod assemblies inside the body. Keep

the pistons square to the body. (This is very

important in the 30, 40R actuator where steel

set screws can cause internal body damage if

the piston assemblies “cock” inside the actu-

ator body).

IMPORTANT:

One piston guide rod assembly

has a through hole drilled in it. It can be easily

located by looking down the ends of both

guide rods. This piston assembly must be

reassembled, with its respective guide rod,

opposite the nameplate on the body, as it was

removed.

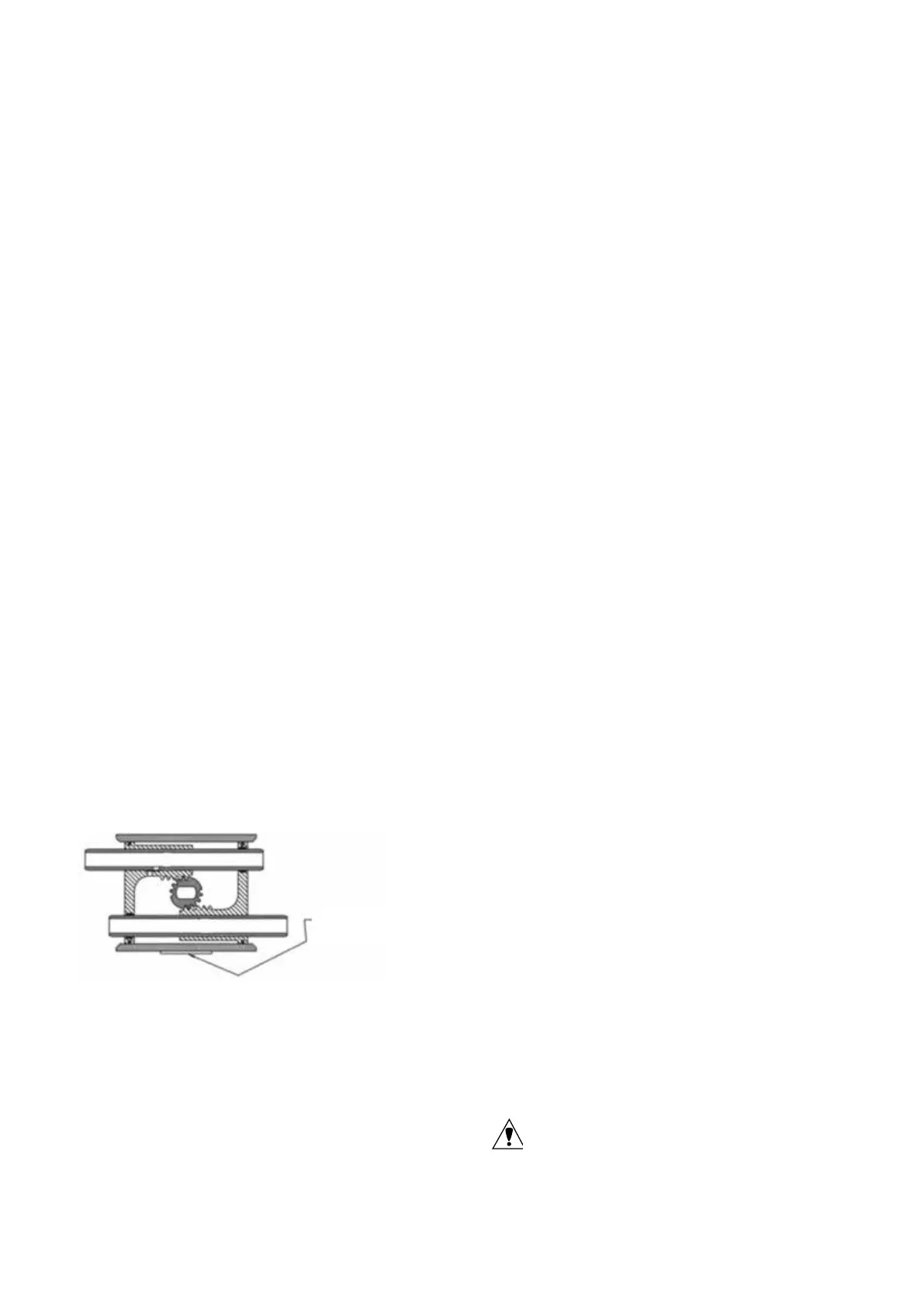

IMPORTANT: Note the relative location of the

shaft teeth and the piston assembly's rack

teeth. The above figure is viewed when looking

at the top of the actuator.

For size 05, align the pistons inside the body.

Keep the pistons square to the body.

VERY IMPORTANT: Install the NEW shaft clip

(15F) into its mating groove on the top shaft

extension. (The removed shaft clip is not to be

reused).

Place the numbered side up on the shaft clip

and be certain the clip is fully seated in its

groove. See Note at bottom of page 10 for

installation of spiral-ring type shaft clip (which

newer rebuilding kits will contain).

14.2.7 Align the shaft so that the teeth on the shaft

will “pick-up” the piston assembly’s rack teeth

when turning the

top extension of the shaft

clockwise (CW). (See Figure 1).

IMPORTANT: Proper 90° rotation can only

be ensured if the shaft teeth begin to mesh

with the piston assembly’s teeth at the “proper

tooth” between these meshing gear pairs.

(See Figure 1).

14.2.8 To ensure proper meshing of teeth, move

the shaft 15 to 20 degrees counter-clockwise

(CCW) from its normal position when the

piston assemblies are located at the body

ends. (See Figure 2.) NOTE: The “normal posi-

tion” of the shaft on the 05–20 sizes is when

the top flats are parallel to the main axis of the

actuator body. On the 25– 50 sizes the teeth of

the shaft will be on the left side of the actuator

when viewed from the ends of actuator. (See

Figure 1).

14.2.9

With the piston assemblies in the body, gently

push each piston into the body. Turn the top

shaft extension clockwise (CW). Do not allow

the pistons to “cock”.

At the proper point of engagement between

the shaft and piston assemblies, both piston

assemblies will move toward the center of the

body when turning the top shaft extension of

the actuator clockwise (CW).

14.2.10

Once the shaft and pistons are properly

engaged, ensure that smooth movement

and 90 degree operation can occur without

moving the pistons out of the actuator body.

This is important!

CAUTION: For sizes 40 to 50 limit stop variant,

the limit stop end cap must be assembled

first. Once assembled, feed the limit stop bolts

through the guide rods and screw into the end

cap. Add the sealing washer, backing washer

and lock nut and then attach the air inlet end

cap. This should be done in conjunction with

the instructions below.

Figure 1

Pistons at End of Body

°

Nameplate

Loading...

Loading...