7.4 Recommended Tubing Sizes:

In order to provide sufficient flow of supply

air to the Series 40R actuator, the following

tubing sizes are recommended:

Actuator Size

Runs Up To

1.5 m Long

Runs Over

1.5 m Long

05, 10, 15, 20, 25

1

/

8

¼

30, 33, 35, 40, 42,

45

¼

3

/

8

50 ¼ ½

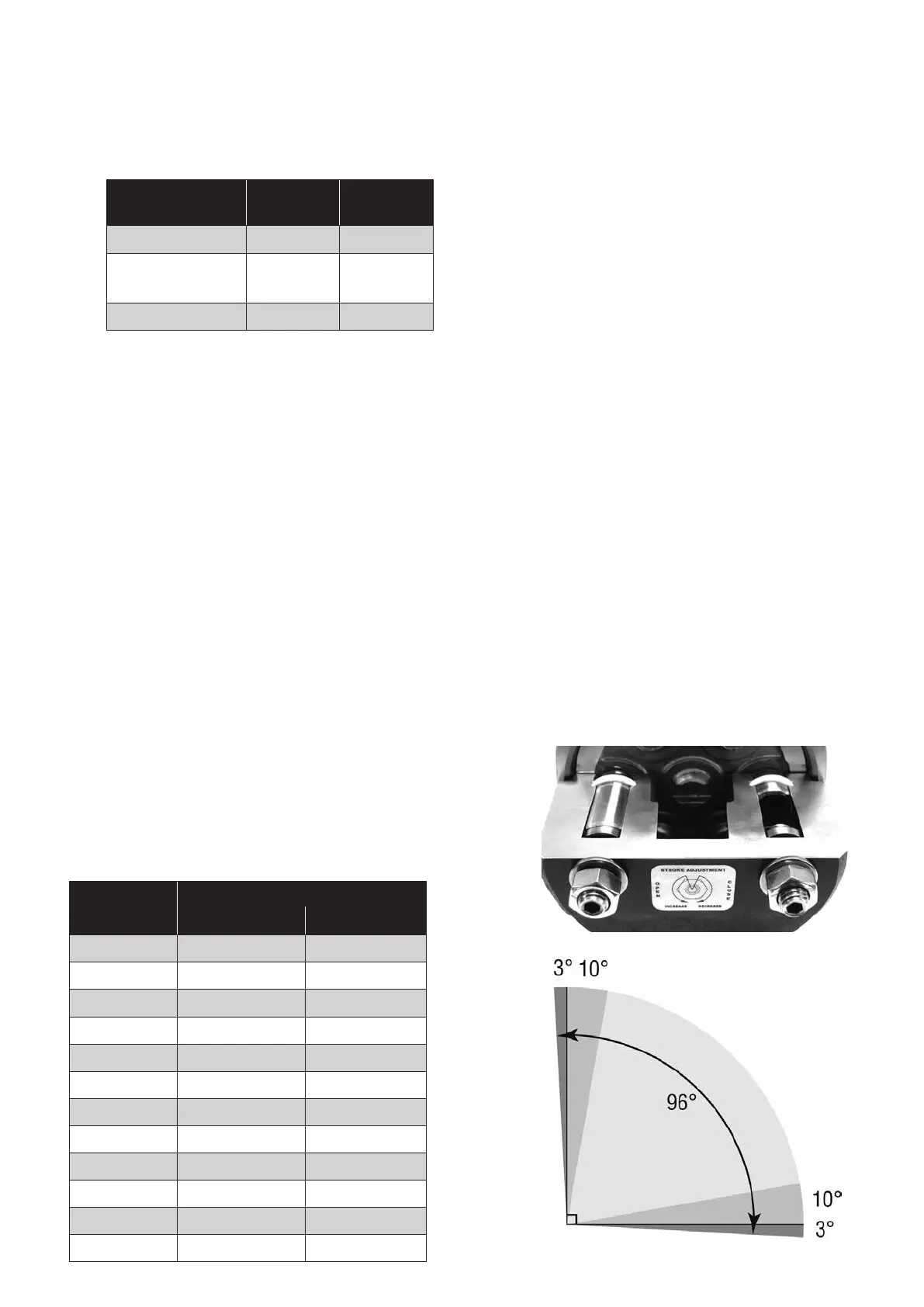

8 AIR CONSUMPTION

The following chart shows the amount of

pressurized (5 bar) air consumed per stroke

in litres. To determine the total amount of air

consumed per complete cycle for double-

acting actuators, simply add the volumes for

both the opening and closing strokes together;

for spring return units, the total volume of

air consumed is the volume shown for the

opening stroke.

9

INSTALLATION ACCESSORIES

For details of installation of accessories refer

to the installation instructions contained in

respective accessory kit.

10 OPERATION

10.1 Basic Actuator

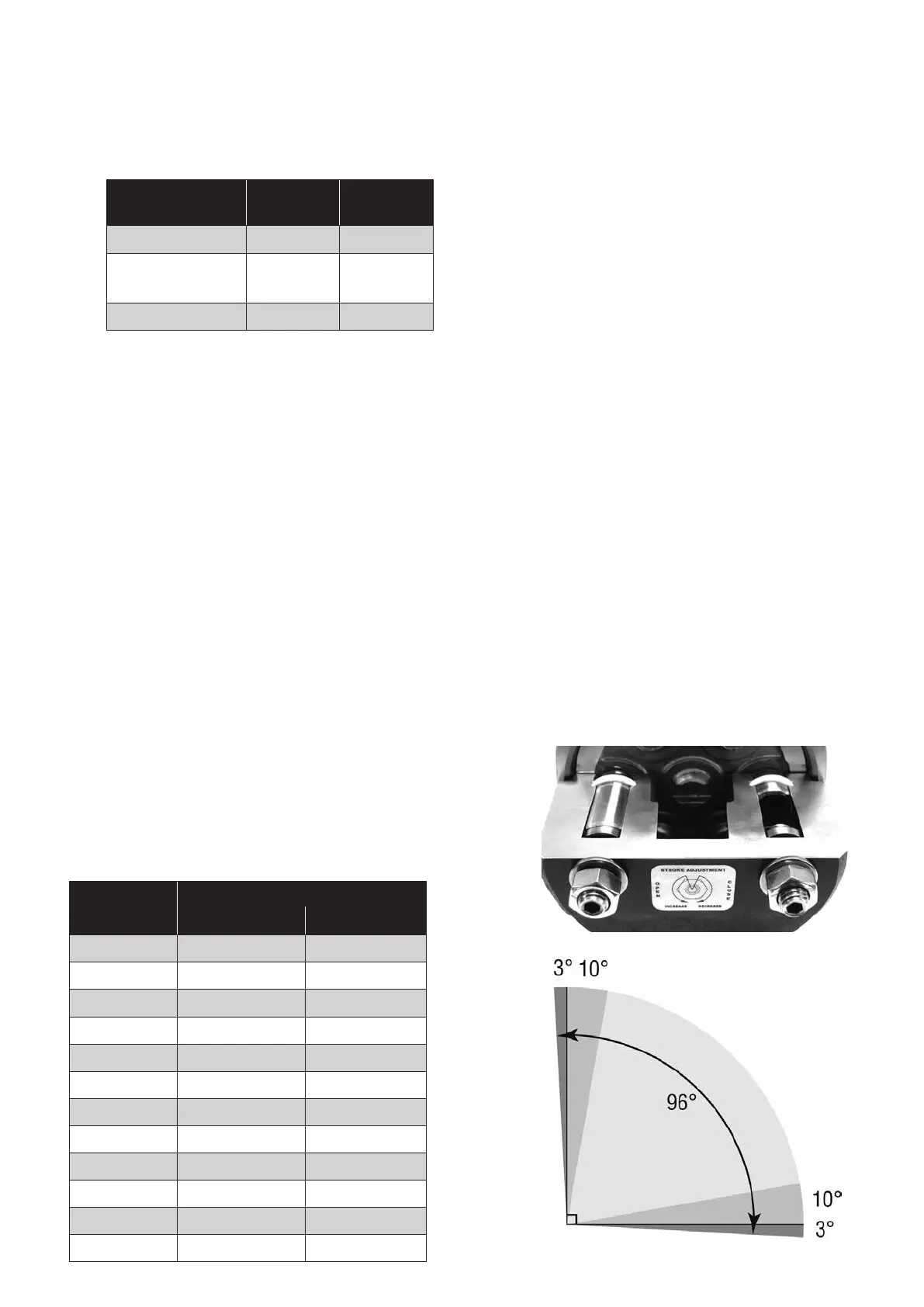

The Series 40R actuator drive shaft rotates

through a full 90° segment with approximately

3° overtravel at each end of travel (limit stop

version). Rotation is accomplished by feeding

supply air into the center chamber, forcing

the two opposing pistons apart, resulting in

a counter-clockwise rotation of the drive shaft

to the “open” position. For double-acting actu-

ators, closure is obtained by feeding supply

air into the end cap chambers, which forces

the pistons together, resulting in a clockwise

rotation of the drive pinion. For spring-return

actuators, closure is accomplished by means

of springs contained within the end caps which

force the pistons together when the supply air

to the center chamber has been interrupted.

If rotation opposite to that described above is

required, refer to the section on Installation for

the proper procedure to reverse the rotation.

The accurate rotation of the actuator pinion

is controlled through the adjustment of two

hexagon headed bolts on the end cap. Each

bolt will control either the open or closing

stroke (based on how the actuator has been

orientated on the valve). The adjustment of

each bolt is shown on the end cap. Actuators

are factory set to provide a 90˚ operation. If

adjustment needs to be made the lock nut

will need to be backed off, the adjustment

screw rotated to provide correct positioning

Actuator

Size

Air consumption litres

Opening Stroke Closing Stroke

05 0.05 0.05

10 0.17 0.22

15 0.35 0.39

20 0.69 0.74

25 1.22 1.31

30 1.86 2.05

33 3.39 4.79

35 3.93 5.54

40 7.73 8.19

42 12.0 13.89

45 13.51 20.0

50 23.87 30.5

Loading...

Loading...