Series 40R Sizes 10 - 42

4.5 bar - 8 springs - 4 per end cap. Remove center spring.

4.0 bar - 8 springs - 4 per end cap. Remove center spring.

3.5 bar - 6 springs - 3 per end cap. Use three on a diagonal.

3.0 bar - 4 springs - 2 per end cap. Use two in opposite corners.

Series 40 Sizes 45 - 50

4.5 bar - 20 springs - 10 per end cap.

Remove required number of

springs starting in the center.

Remaining springs should be

evenly spaced as possible.

4.0 bar - 20 springs - 10 per end cap.

3.5 bar - 16 springs - 8 per end cap.

3.0 bar - 12 springs - 6 per end cap.

The size 05 spring-return actuator operating at 5.5 bar has four

springs (two per end cap). For air supplies of 4.5, 4.0 or 3.0, remove

inner spring of each end cap.

14.2.11

Install O-Ring (15A) into and replace the

actuator end caps, (5 or 5A and 5B), noting

that the “foolproof” pin between the body and

end cap mates properly (10–50 sizes only).

NOTE: For spring return actuators, see

spring installation section on page 13 before

installing end caps.

NOTE: When installing the end cap O-Rings,

use a small amount of a general purpose lubri-

cant, such as petroleum jelly, to hold them in

place for ease of assembly and to avoid having

them drop down and get pinched.

On Rev. R2 and earlier actuators, be sure

O-Ring is installed in groove on end cap.

14.2.12

Replace position indicator (17). See Section 6.

15 SPRING-RETURN ACTUATOR

15.1 When replacing springs in a spring-return

actuator, ensure that the springs are replaced

in their identical position in the end cap from

where they were removed.

IMPORTANT: When less than the standard

number of springs are used in each end cap,

these springs should be positioned according

to the air supply figures below.

The values listed below are for standard and

less than the standard air pressure as required

per the ordering code.

NOTE: Maximum operating pressure does not

change.

15.2 If a spring-return actuator is being repaired

due to a failed spring, REPLACE all the springs

in this actuator, as well as any other parts

which may have been damaged.

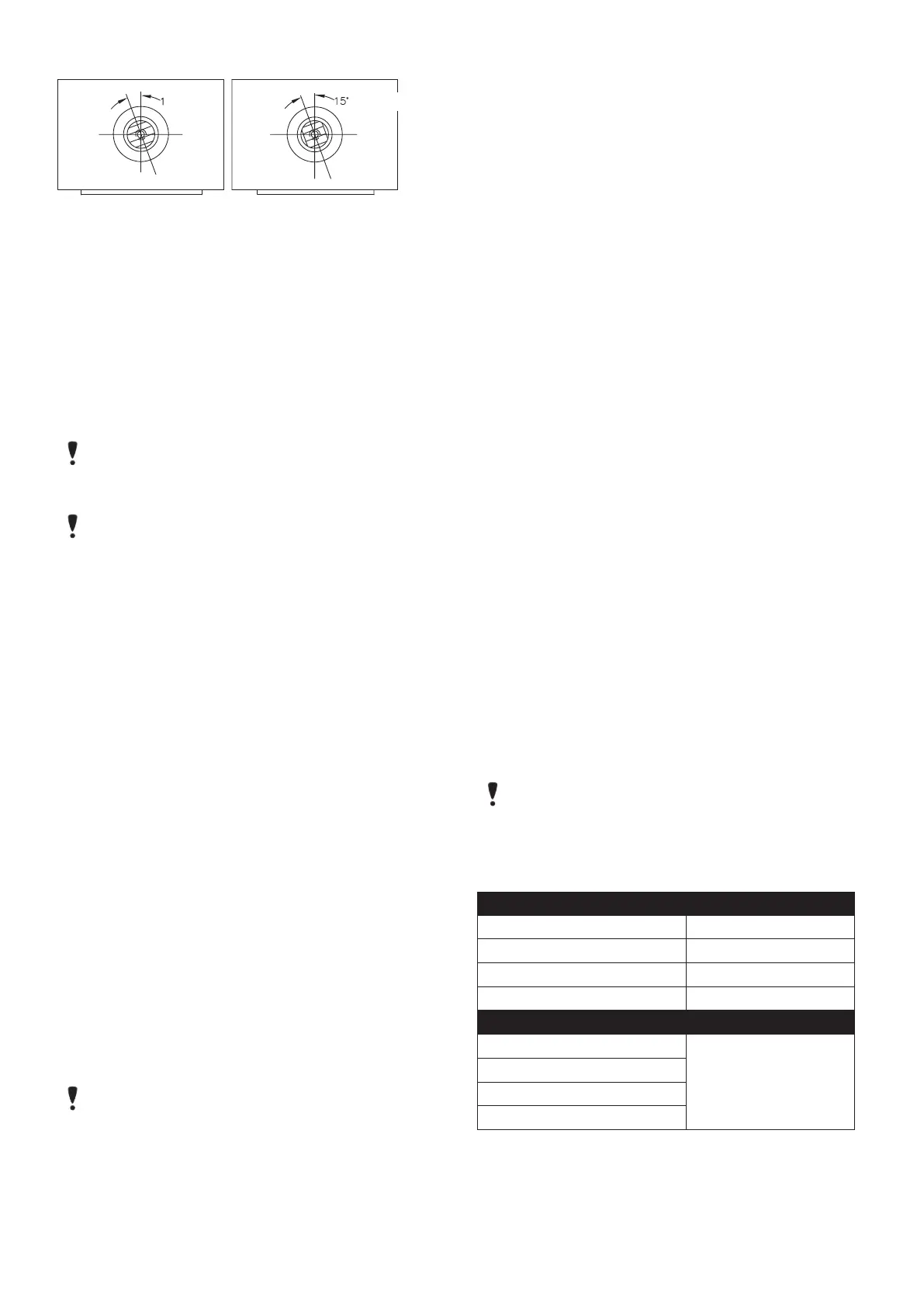

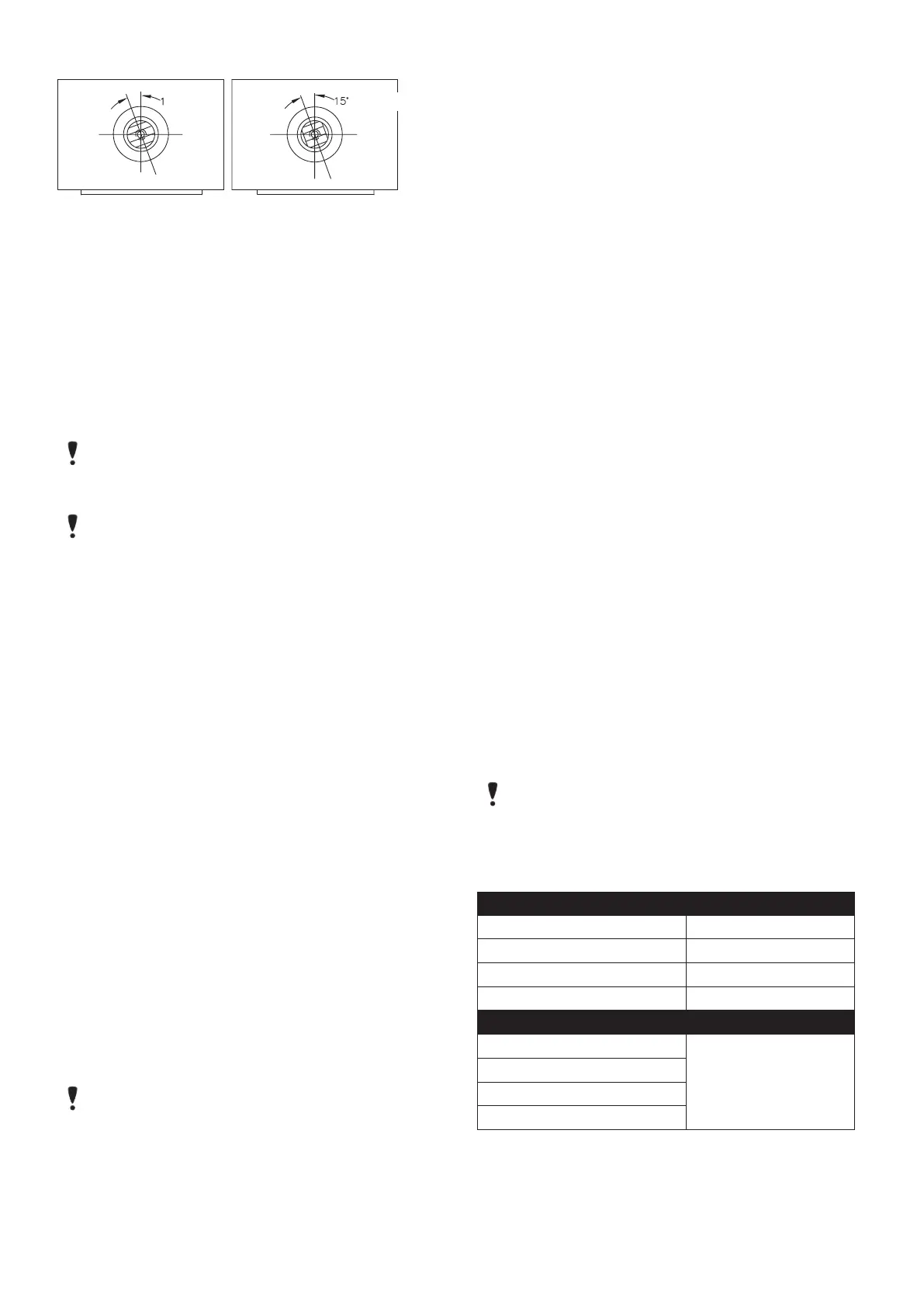

Size 05 - 20 Size 25 - 50

15˚ - 20˚

15˚ - 20˚

Figure 2

Alignment of Shaft at Reassembly

IMPORTANT:

Align gear teeth on the shaft as per Figure 1.

15.3 When replacing the springs in a spring-re-

turn actuator, place the springs in the end

cap pocket after thoroughly lubricating each

spring. Be generous with lubricant!

15.4 With the springs pointing up and the end cap

on a solid surface, place the actuator body

over the springs and the proper end cap. (Each

end cap can only be mounted to just one end

of the actuator body, as there is a “foolproof”

pin in the end cap, which aligns with a hole in

the body).

15.5 Force the body down and begin by engaging

two end cap screws (5C) by hand through

the end cap. Take each end cap screw up in

SMALL and EQUAL turns. Once the end cap is

temporarily secured to the body, turn the actu-

ator over to its normal position and uniformly

take up the four end cap screws. Uniformly

load all the springs to prevent any spring from

buckling.

IMPORTANT: Locating nibs are cast into the

piston face on sizes 25 to 50. The actuator

springs must fit over these locating nibs on

the piston face. Care in following the above

instructions will ensure the proper alignment

of the spring in the actuator body — proper

contact with the piston face and end cap.

15.6 In a similar manner, as written in the previous

steps, replace the springs in the other end of

the actuator body.

NOTE: On sizes 40 to 50 limit stop, only

encapsulated springs (pre-compressed) can

be used with this design.

Loading...

Loading...