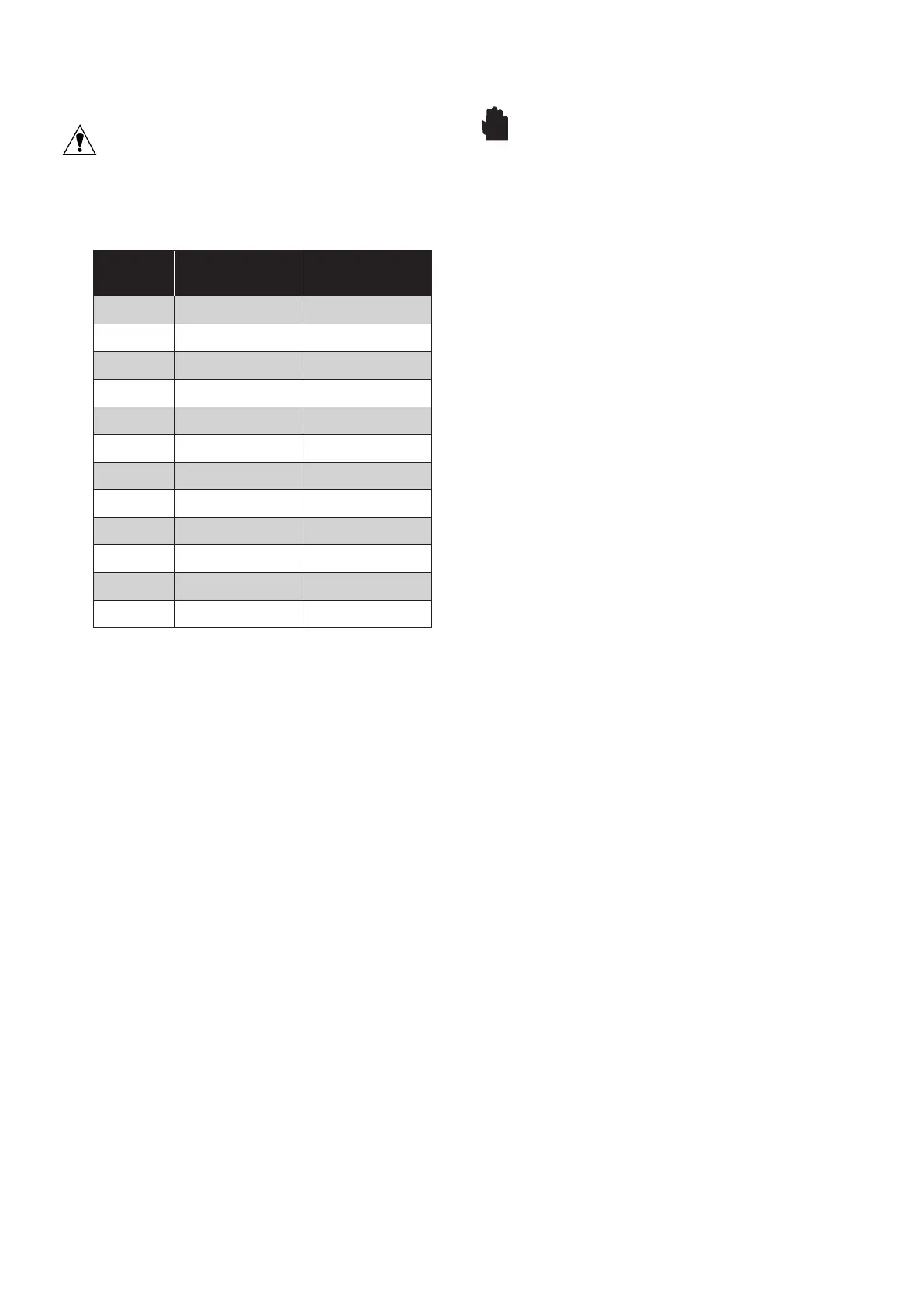

Actuator

size

Fastener size Torque

05 M5 4Nm

10 M6 9Nm

15 M6 9Nm

20 M8 19Nm

25 M8 19Nm

30 M10 35Nm

33 M10 35Nm

35 M12 49Nm

40 M12 49Nm

42 M16 98Nm

45 M16 98Nm

45 M20 216Nm

11 MAINTENANCE

CAUTION: The actuator must be isolated

both pneumatically and electrically before any

maintenance activity is begun.

Periodic checks should be performed to make

certain that all fasteners remain tight.

All actuators are supplied with sufficient lubri-

cation for their normal working life. If required,

recommended lubrication for all standard

actuators is a Rocol Sapphire Lo-Temp 2

grease. Consult Flowserve for lubricants used

for high or low temperature applications.

Depending upon the conditions under which

the actuator must work, such as extended duty,

non-compatible operating media or abnormal

operating conditions, periodic replacement

of internal seals is recommended. Repair kits

containing all necessary seals can be obtained

through any authorized Flowserve distributor.

On spring-return actuators, the springs may

need replacement after extended duty since

springs may fatigue and break. SPRINGS

SHOULD ALWAYS BE REPLACED IN

COMPLETE SETS.

12

SPARE PARTS

The following are recommended spare parts

which should be kept on hand for Series 40R

pneumatic actuators:

Repair Kit(s) – Kits contain all necessary seals,

bearings and instructions.

13

TROUBLESHOOTING

WARNING:

BEFORE DISASSEMBLING

ACTUATOR FOR ANY REASON, CONSULT

REBUILDING INSTRUCTIONS CONTAINED IN

FOLLOWING SECTION.

For solenoid controlled actuators:

13.1 If actuator does not function, check to ascer-

tain:

13.1.1 That valve is free to rotate.

13.1.2 That actuator is the correct size.

13.1 3 Any speed control screws are loose (if screws

are tightened all the way, actuator will not

operate).

13.1.4 That correct voltage is supplied to solenoid.

13.1.5 That sufficient air supply is available at inlet to

control block. Inlet pressure to control block

should be at least 2.5 bar for double-acting, 5

bar for spring-return (unless a reduced spring

complement is installed (fewer springs)).

When checking supply pressure, place gauge

in line at control block inlet and monitor gauge

for unexpected pressure drops.

13.2 If proper voltage and air pressure have been

verified and valve is free, proceed as follows:

13.2.1 Turn on signal voltage. Check solenoid for

clicking sound.

13.2.2 If no sound is detected, remove air pressure

and turn off signal voltage.

• Carefully unscrew solenoid and solenoid

stem from block.

• Reapply signal voltage and observe solnoid

plunger. If it does not retract, replace solenoid.

13.2.3 If solenoid functions, remove solenoid valve

block and place on bench. Connect to reduced

air supply (4 bar) and correct voltage. Switch

signal voltage and check air flow. Air should

flow out only one output port when solenoid

is energized. The flow should occur only at the

other port when de-energized. (Slight back

pressure may be required to shift the valve

spool. This may be generated by obstructing

the outlet ports.)

Loading...

Loading...