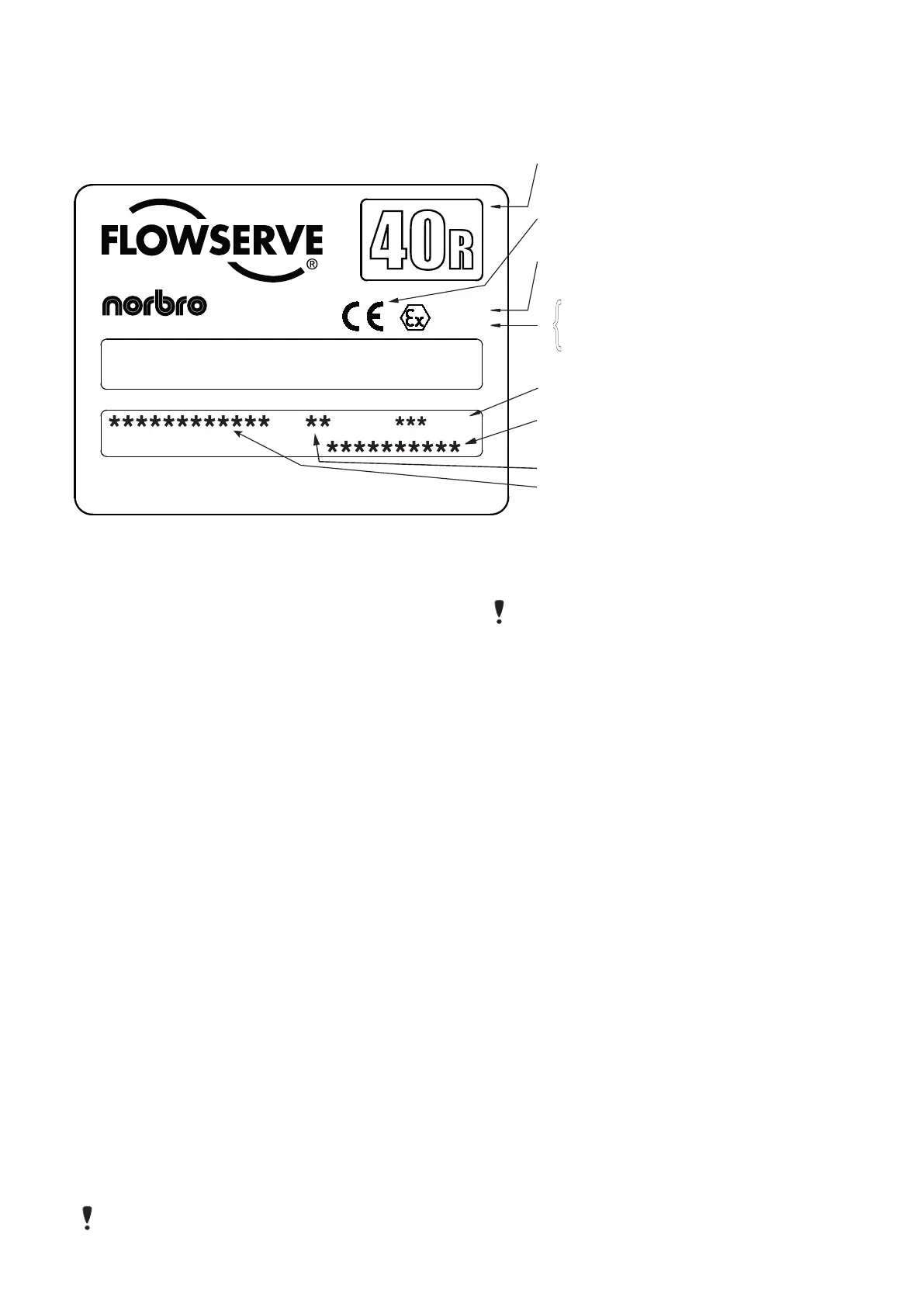

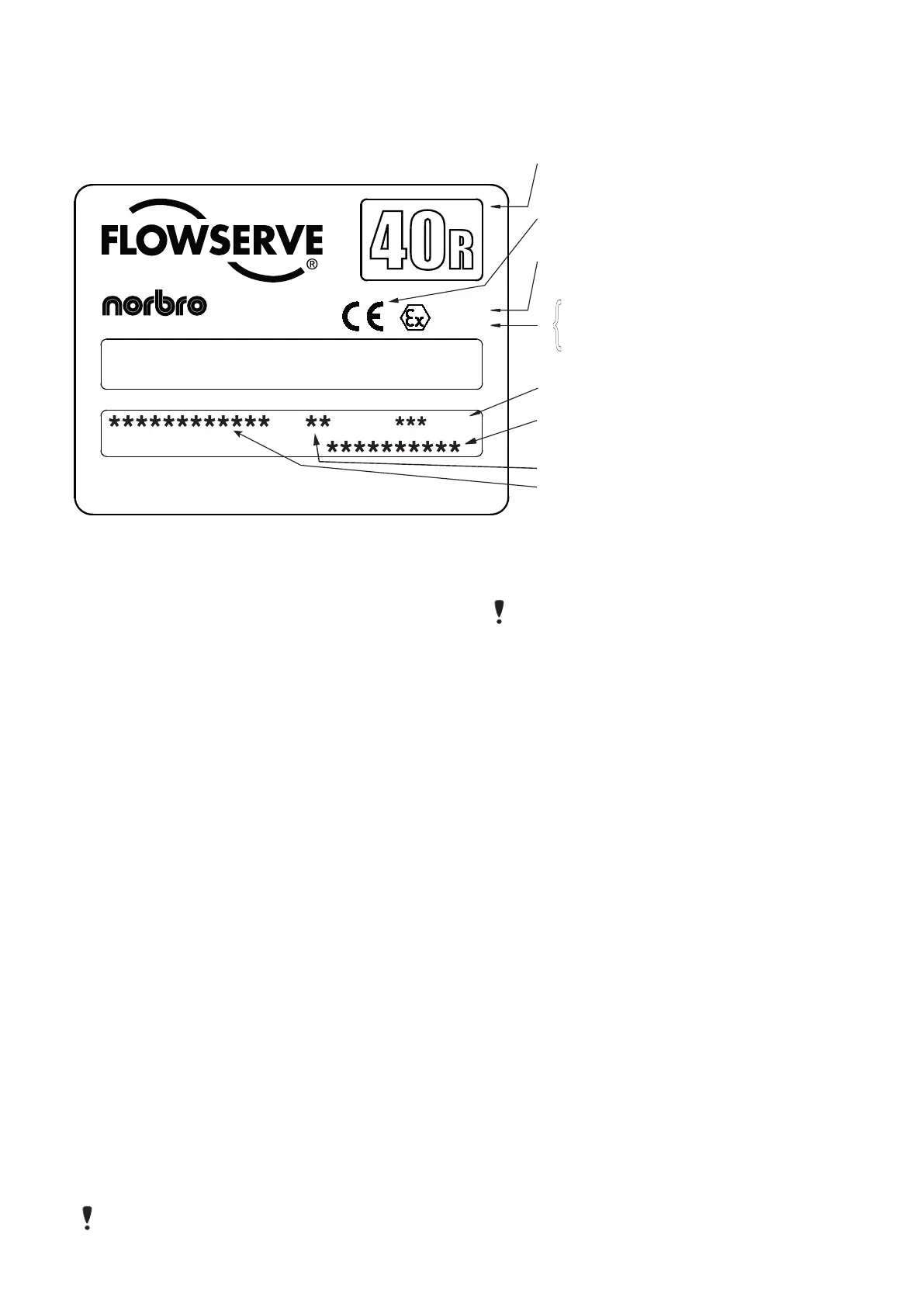

4 ACTUATOR MARKINGS

Each actuator has the following identification infor-

mation on the product label attached to the side of

the body:

ATEX Directive: If the product label carries the ATEX

Directive number '94/9/EC' followed by the Explo-

sion Protection Symbol and codes identifying the

equipment group and category, the zone suitability

and protection type beside the CE mark, the product

complies with the ATEX Directive and The Equipment

and Protective Systems Intended for Use in Poten-

tially Explosive Atmospheres Regulations 1996.

Definition of product label marking above:

'II' = Equipment Group.

'2' = Equipment Category.

'G' = Gas Zone suitability (Zones 1 & 2).

'D' = Dust Zone suitability (Zones 21 & 22).

'c' = type of protection i.e. constructional safety (prEN

13463-5).

'X' = Special temperature reference (Surface

Temperature: As per BS EN 13463-1:2001 paragraph

14.2g, the temperature class or maximum surface

temperature cannot be marked on the product as it is

dependent on the operating conditions).

The operational temperature range is as follows:

(S) = Standard -20 °C to +100 °C.

(L) = Low Temperature variant -40 °C to +85 °C.

(H) = High Temperature variant -20 °C to +150 °C.

NOTE:

Under constant use the surface tempera-

ture of expose parts may rise by a maximum

20 °C above the operating media temperature.

5 INSTALLATION

NOTE:

The Series 40R actuator is normally

installed with its major axis parallel to the

pipe line. The actuator can be oriented above,

beside or beneath the valve without affecting

its operation.

Sizes 10-35 actuators may come with an ISO

locating ring, used for optional ISO mounting.

Size 40-50 actuators have an integral ISO

location ring.

5.1 Determine mode of operation desired

(normally open or normally closed) of the

valve.

5.2 Determine desired quadrant for bracket

attachment and direction of mounting of actu-

ator (in-line or cross-line).

5.3 Attach mounting bracket to actuator using four

(4) cap screws and lock washers provided in

mounting kit. To avoid any damage to the

Series 40R actuator body, ONLY the proper

length screws supplied with the mounting kit

should be used.

5.4 If an ISO locating ring is used, insert ISO

locating ring into groove on bottom of actu-

ator before attaching to bracket. Ring can

be permanently held in groove by applying

Loctite

®

638 to ring before inserting in groove.

Maximum Working Pressure

Works Order Number

Year of Manufacture

Atex Directive

Product Series

Explosion Protection Symbol,

Equipment Group & Category,

Zone Suitability and Protection Type

CE Mark

Flowserve Flow Control (UK) Ltd

Product Code

Website: www.flowserve.com UK & Foreign Patents

IMPORTANT: Dismantle only in accordance with Installation,

Operation & Maintenance notes. Refer to notes to ensure proper

use of actuator. Maximum Working Pressure see below.

WORKS ORDER

II2GDcX

94/9/EC

Flowserve Flow Control (UK) Ltd.

Tel: +44(0)1444 314400 Fax: +44(0)1444 314401

PRODUCT CODE

PNEUMATIC ACTUATOR

YEAR

{

BAR

Loading...

Loading...