19.SENSORS CONNECTION

19.1 RPM SENSOR

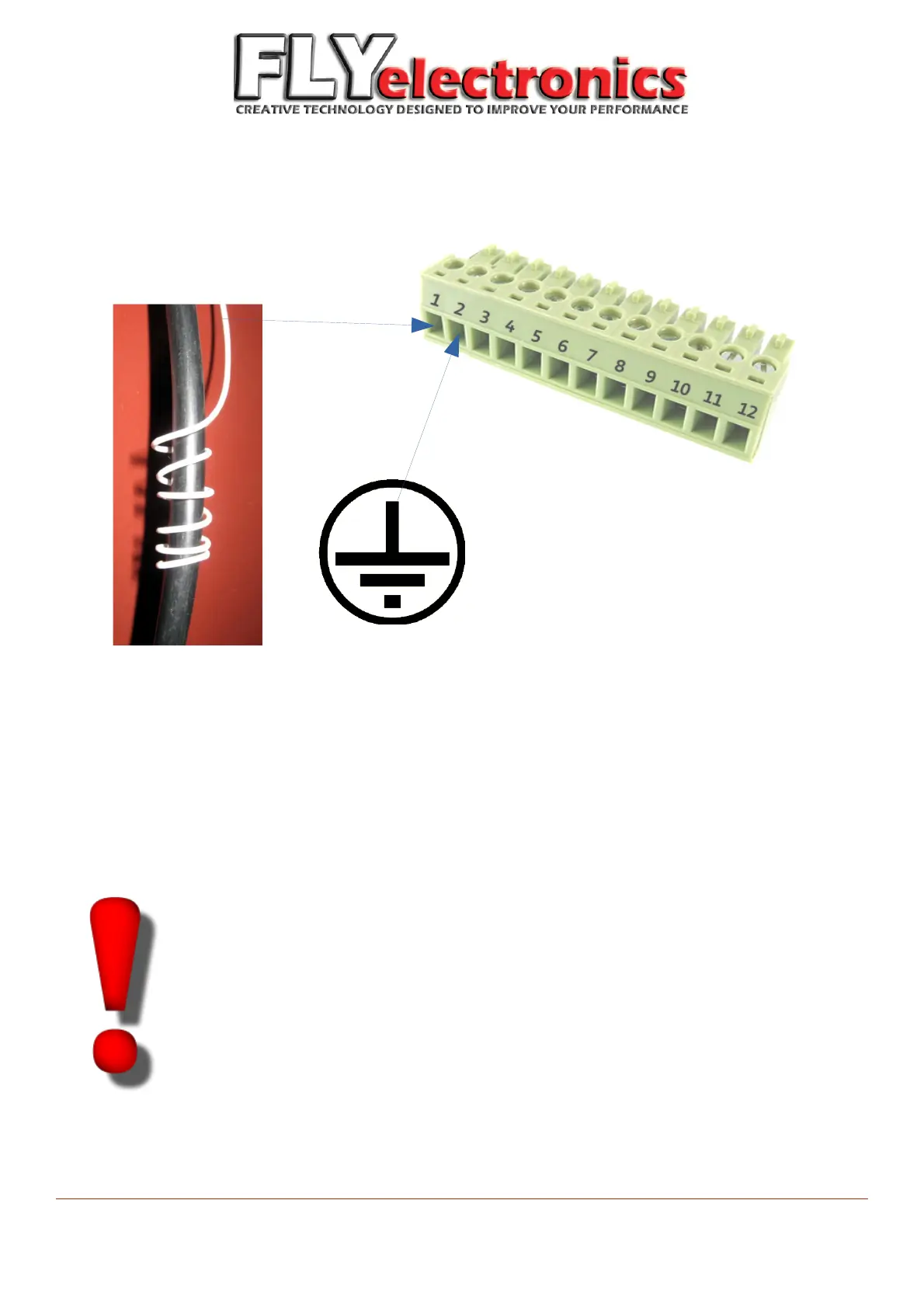

RPM sensor does not require interference in PPG electrical system. For the device to work properly, user

should wind a piece of isolated copper cable on PPG high-voltage cable, as shown above. The amount of

rolls depends on individual PPG, but normally it is between 2 and 10. It is wise to isolate the coil, so that it

does not unroll due to vibration. Then, connect the coil to first pin of connector.

It is also useful to connect PPG Ground (not frame ground) to pin number 2.

Please perform some tests in order to correctly choose the amount of rolls. We

suggest use 4 first, and check if the device picks up RPMs. If the RPM is not picked

up (or picked up on higher values only) – add one more roll.

In order for the device to work properly and pick up RPM, you need to use spark

plug with resistor.

In case of intermittent connection between transmitter and receiver, you should

change your spark plug to new one. Faulty resistor causes worse burning rate – it is

not noticeable by user, but causes strong electromagnetic noise around the wire.

FLYelectronics All Rights Reserved Page 25

Loading...

Loading...