Troubleshooting | 73

FRAKO | Operating Manual | Power Quality Controller – PQC

9 Troubleshooting

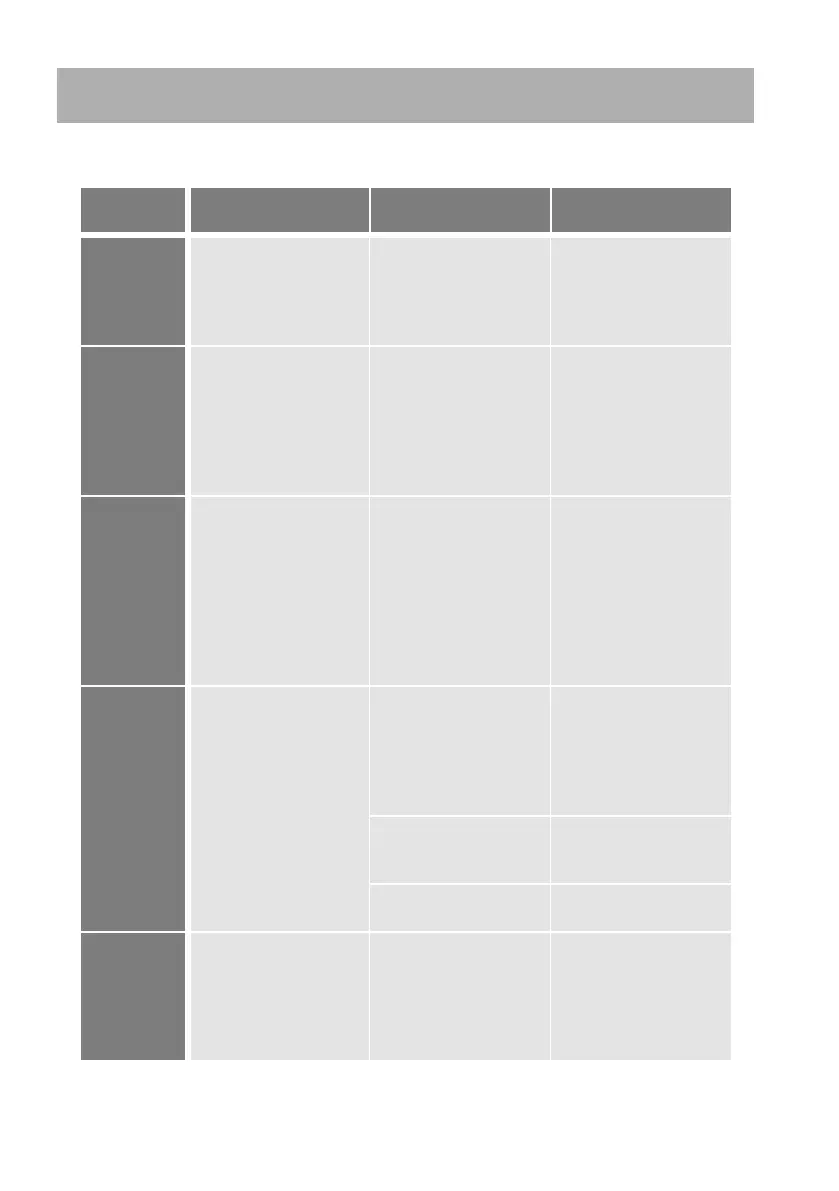

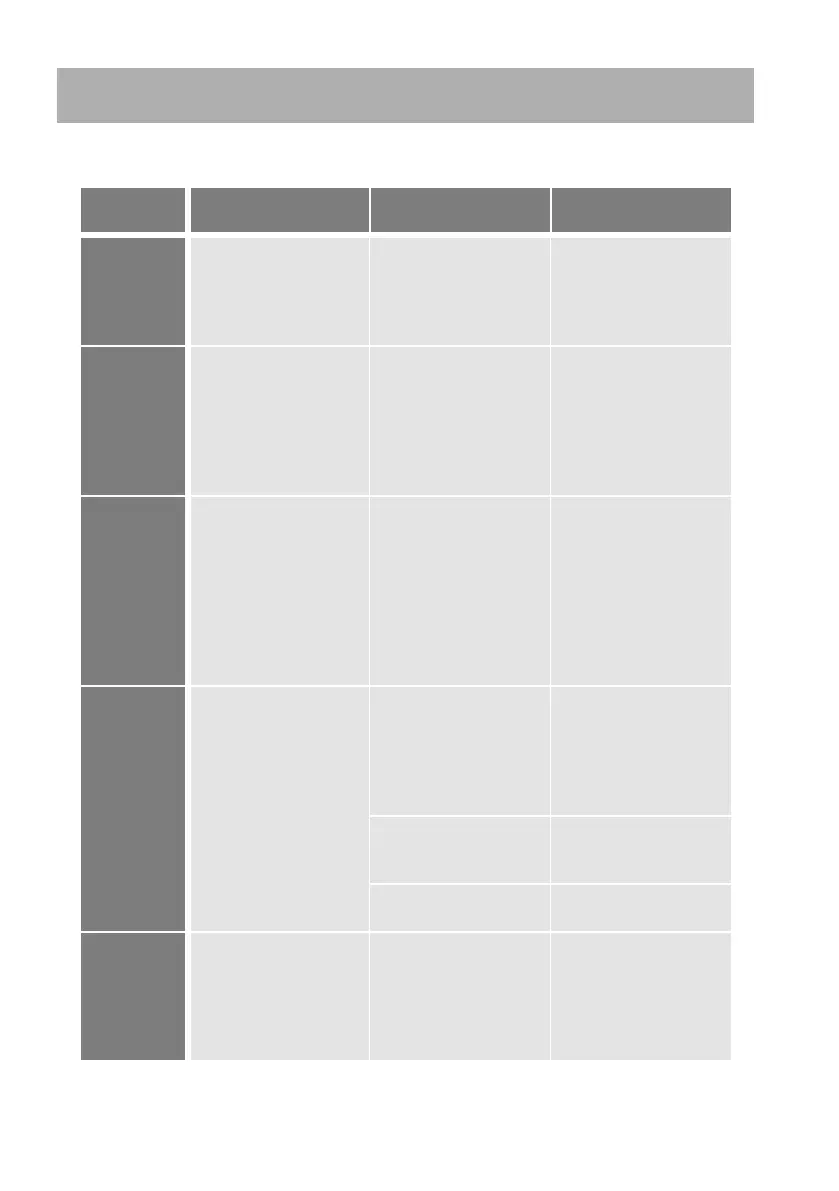

If alarms occur during operation of the PQC, the following table provides assistance

in identifying and remedying the faults.

Alarm

message

Fault Possible cause Remedial action

PQC not working;

no display at front of

instrument

No power – or the wrong

voltage – connected

Check that the correct

instrument power supply

is connected and that

the fuse in the circuit has

not blown.

cosφ cannot

be achieved

PQC gives a cosφ alarm

although the momentary

cosφ is better (nearer to

1) than the target value.

More capacitive than

the control band but still

inductive

See Section 6.3.4.2

“Cosφ Alarm”

for control band alarm

settings.

See Section 6.3.4.2

“Cosφ Alarm”

for control band alarm

settings.

Voltage < set

limit

PQC indicates or states

that voltage is less than

set alarm limit, although

a voltage is shown on

the screen.

The alarm limit has not

been adjusted for the

network nominal voltage.

Default setting is for 400

V networks.

Triggered when the

network voltage is less

than 85 % of the nominal

voltage.

Set the correct alarm

limit for the network

nominal voltage (see

Section 6.3.1 “System

parameters”)

Current < set

limit

No value for current

shown in the display

(0 A)

Break or short-circuit in

the current transformer

cable

Use an ammeter to

check current in current

path (I

min

* 0.015 A).

Danger: see

Section 5.2.7 “Current

measurement”

The current in the current

path is too low.

(I

min

* 0.015 A)

Install a smaller current

transformer.

Defective current

transformer

Check the current

transformer.

Voltage <

set limit +

Current < set

limit

PQC shows no meas-

ured voltage and no

current, although it has

been verified that power

is connected and a

current is flowing.

Multiple zero-voltage

crossings in measured

voltage.

Settings for the Network

nominal parameters

–> Change setting from

Auto to the appropriate

network frequency (50

Hz or 60 Hz).

Loading...

Loading...