a station attendant or activate the service

station emergency shut-off switch to cease the

flow of CNG.

9.

Switch on the service pump. A slight hissing

noise may be heard as the fuel cylinders fill.

10.

Watch the pressure gauge on the service pump.

When the gauge reads approximately 3600 psi

(24 800 kPa), or when the fill pressure stops

climbing, the CNG cylinders are full. The service

pump will shut itself down automatically. See

Table 19.1 for pressure compensation values

based on ambient temperatures.

11.

Move the selector knob on the service pump to

the VENT position, if equipped. A short hiss will

be heard as a small amount of natural gas is

vented into the hose.

WARNING

Do not attempt to remove the fill station nozzle

from the tank fill fitting until venting of pressure

is noted. If no venting occurs, ask for assistance

from the station attendant. Removing an

unvented coupling could result in an

uncontrolled hose, which could lead to property

damage or personal injury.

12.

Remove the station dispensing nozzle from the

vehicle fill port.

13.

Install the dust cap on the vehicle fuel fill port

and close the fuel panel access door.

LNG Vehicle Fueling

The LNG fuel tank is designed to be filled from any

LNG fuel source that has a 100 micron or finer fuel

filter and a fuel delivery pressure between 120 and

225 psi (827 and 1551 kPa).

The LNG fuel tank is designed to be top-filled

through a single hose with no vent return. As cold

LNG is sprayed into the vapor space of the tank, the

cold liquid condenses the vapor and creates space

for itself inside the tank, eliminating any need to vent

during the filling process.

The LNG tank is equipped with a small internal

ullage tank for vapor space, which allows for fuel

expansion and increases vehicle standby time. When

an LNG tank is full, fuel can continue to flow into the

ullage tank. However, if the ullage tank is completely

filled during fueling, standby time will be reduced to

zero and the primary relief valve will open almost

immediately after fueling, allowing excess LNG vapor

to escape. If fueling is stopped when the ullage tank

is empty (i.e., the fuel tank has sufficient vapor space

to accommodate fuel expansion due to temperature

increase), the vehicle will have approximately one

week of standby time before venting will occur.

Use the following steps to fuel an LNG vehicle.

1.

Shut down the engine and apply the parking

brake.

IMPORTANT: Close all windows and doors

during the fueling process. Keeping windows

and doors closed allows for easier leak

detection inside the cab after fueling.

WARNING

Liquefied natural gas is a cryogenic liquid stored

at approximately -259°F (-162°C). Cryogenic

burns can be caused by coming into contact with

the pressurized liquid stream, or by coming into

contact with fuel system components that have

been cooled to cryogenic temperatures. Always

wear gloves and a face shield, and cover

exposed skin when fueling.

2.

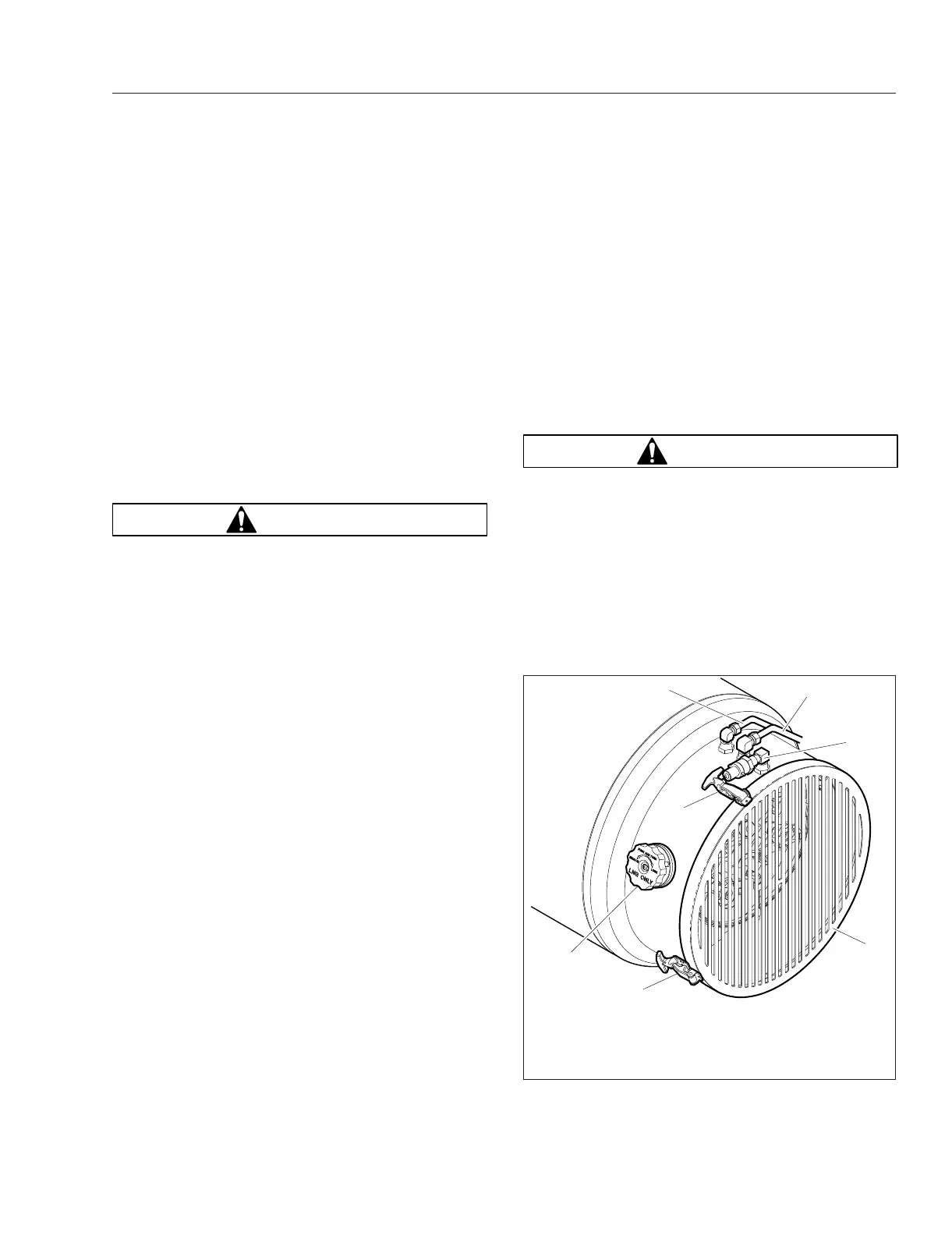

Remove the fuel fill fitting dust cap. See

Fig. 19.3.

05/29/2009 f470534

1

2

3

4

6

5

6

1. Fuel Fill Fitting

2. Fuel Outlet Line

3. Primary Relief Vent

Line

4. Fill Vent Fitting

5. Shroud Cover

6. Shroud Cover Latches

Fig. 19.3, LNG Fuel Tank

Natural Gas Vehicle Information

19.4

Loading...

Loading...