3.

Using compressed air, remove any dirt, debris, or

water that may have collected in the fuel fill

fitting and the station dispensing nozzle.

Contaminants in the fuel system can cause

drivability problems.

WARNING

Natural gas fuel tanks, lines, and valves are

always pressurized. Always observe safety

precautions. Failure to do so could lead to loss

of control over a filling hose or to ignition of the

natural gas, which could cause serious bodily

injury, death, or severe property damage.

4.

Connect the station fueling nozzle to the tank

fuel fill fitting.

5.

Connect an electrical ground clamp and cable to

the fuel tank.

IMPORTANT: An LNG tank which is first

installed, or is on a vehicle that has not been

operated in approximately ten days, is

considered to be a hot tank. When fueling a hot

tank, LNG entering the tank will immediately

vaporize, causing tank pressure to spike above

250 psi (1724 kPa) and automatically shutting

down the station fuel pump. To prevent the

pump from shutting down, connect a vent line to

the fill vent fitting on the LNG tank to capture

escaping vapor, then open the shroud cover and

open the vapor shutoff valve. See

Fig. 19.4,

item 2.

6.

Open the station’s fill valve, if equipped, and

start fueling. Monitor the flow or line pressure as

filling progresses. When filling begins, line

pressure will spike quickly until the vehicle tank

cools down. The flow and pressure will then

remain stable during the remainder of the filling

procedure.

IMPORTANT: When fueling a hot tank, initially

put 5 to 10 gallons (19 to 37 liters) of LNG in

the tank and manually stop the fueling process.

Drive the vehicle for 15 to 20 minutes to cool

the tank and reduce tank pressure, then

continue fueling the tank to full.

7.

When the tank is full, the line pressure will

rapidly spike and the flow rate will fall. When a

pressure rise or flow rate drop is observed, close

the station’s fill valve, if equipped.

NOTE: Do not over-fill an LNG tank. If the

ullage tank is completely filled during fueling,

tank standby time will be reduced to zero and

the primary relief valve will open almost

immediately after fueling.

8.

Disconnect the station hose from the tank fuel fill

fitting.

9.

Disconnect the electrical ground clamp and cable

from the fuel tank.

10.

Install the dust cap on the tank fuel fill fitting.

Natural Gas Detection System

A gas detection system is standard equipment in all

Daimler Truck natural-gas-fueled vehicles. This

system has a sensor in the engine compartment and

one in the cab, both situated in high areas to detect

natural gas buildup as a result of leaks. This device

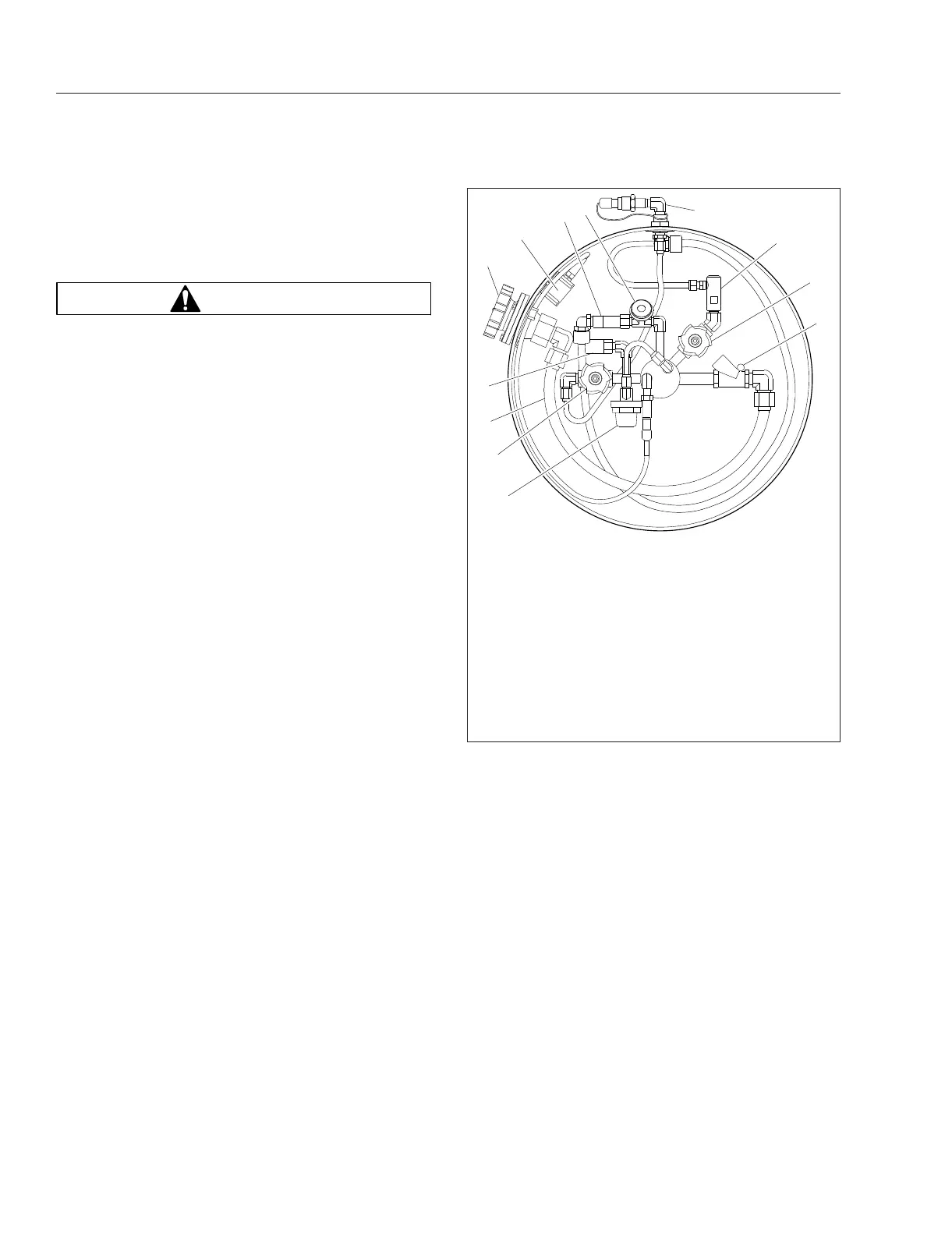

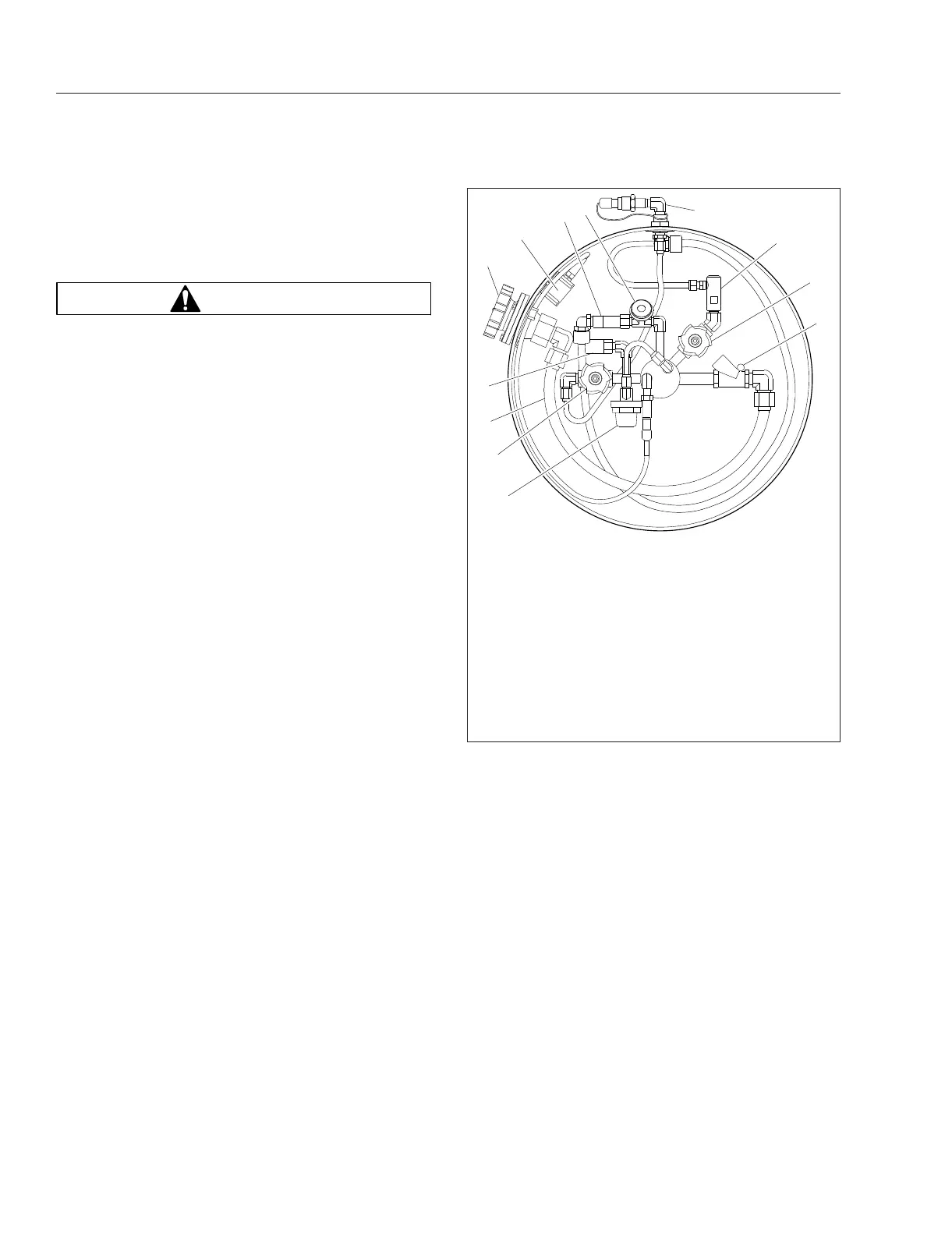

05/05/2010 f470533

1

2

3

4

5

6

7

8

10

11

12

9

1. Pressure Control Regulator

2. Vapor Shutoff Valve

3. Fuel Fill Hose

4. Secondary Relief Valve (red cap)

5. Fuel Fill Fitting

6. Fuel Level Sender Box

7. Primary Relief Valve

8. Tank Pressure Gauge

9. Fill Vent Fitting

10. Excess Flow Valve

11. Fuel Shutoff Valve (liquid)

12. Fill Check Valve

Fig. 19.4, LNG Fuel Tank Plumbing Components

Natural Gas Vehicle Information

19.5

Loading...

Loading...