- 2 -

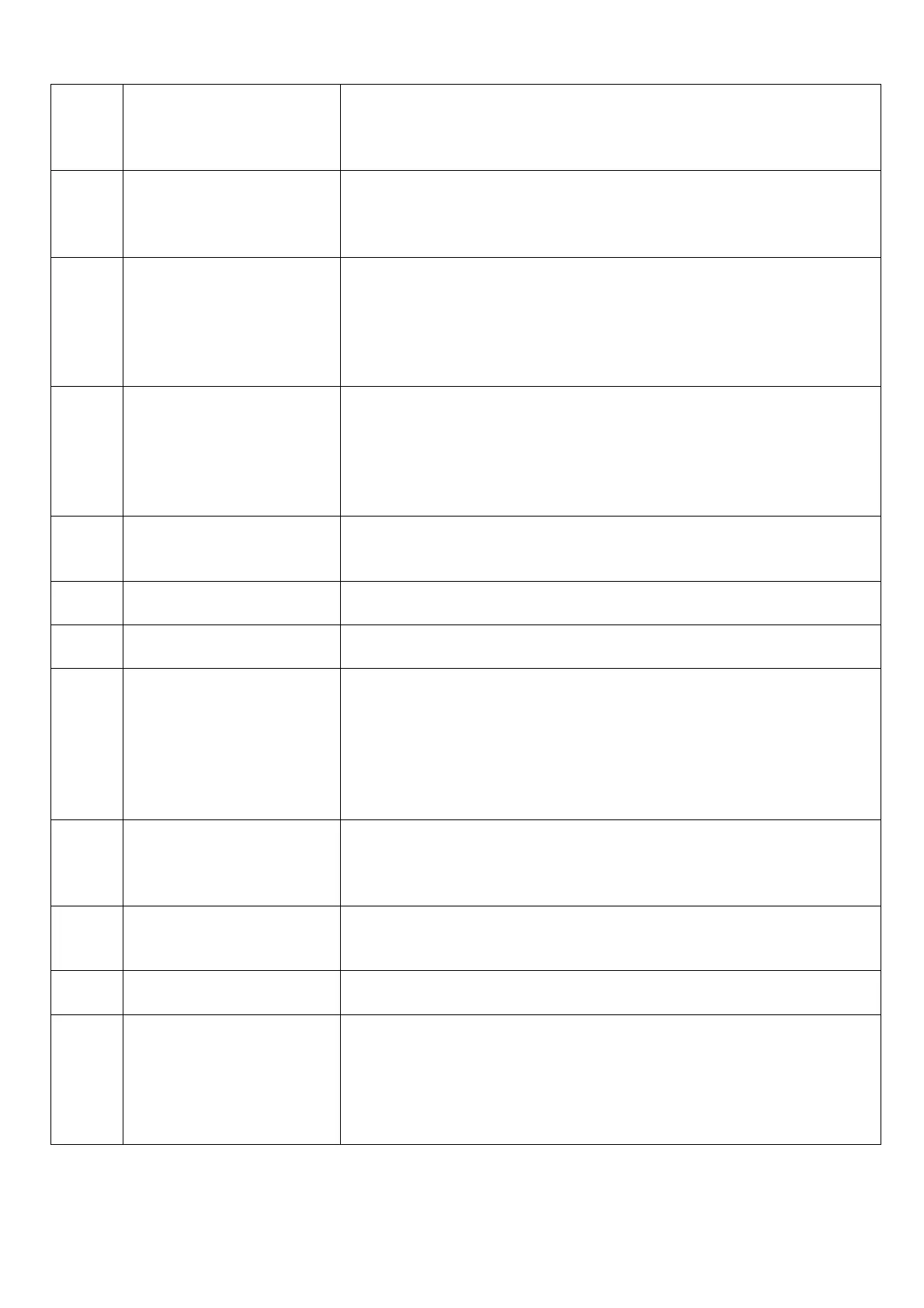

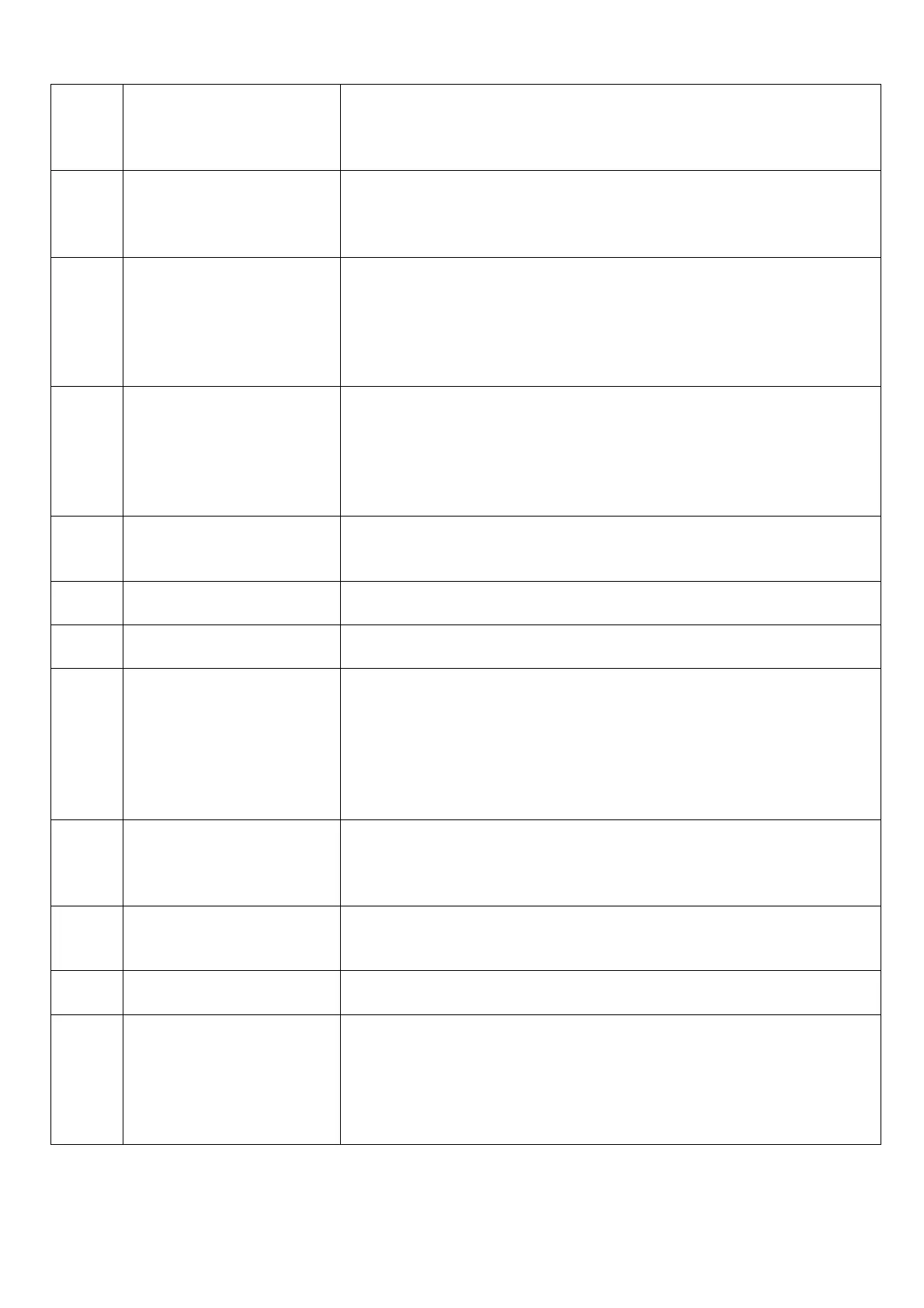

(9)

Alarm display portion

Operation is interrupted and buzzer beeps. And, the details are displayed usi

ng numbers.

0: Load value is NG; 1: Emergency stop order input; 2: Cycle time error is

operated; 9: SD memory card writing error

(10)

OK product display lamp (G

O)

This lamp lights up when value of load is judged as OK. “Lower limit co

mparison value ≦ Load of press-fitting or crimping ≦ Upper limit compari

son value” The signal is output on back surface terminal base Nos. 23 and

24 at relay contact point (normal open).

(11)

NG (upper limit) display lamp

(HI)

In the case that load value surpasses upper limit setting value, this lamp- li

ghts up. “Upper limit comparison value ‹ Load value of press-fitting or crim

ping” signal is output on back surface terminal base Nos. 20 and 22 at rela

y contact point (normal open). Buzzer sounds for two seconds simultaneousl

y when the lamp lights up. ※In the case that alarm display is No. 1 or 2,

the lamp also lights up.

(12)

NG (lower limit) display lamp

(LO)

In the case that load value is lower than lower limit setting value, this lam

p lights up. “Load value of press-fitting or crimping ‹ lower limit compariso

n value” The signal is output on back surface terminal base Nos. 20 and 21

at relay contact point (normal open). Buzzer beeps for two seconds simulta

neously when the lamp lights up. ※In the case that alarm display is No. 1

or 2, the lamp also lights up.

(13)

Load measuring mode display

portion

When measuring of crimping loads or press-fitting loads is completed, either

peak value (initial setting value) or instantaneous value (load value when c

ompleting hold) is displayed.

(14)

Setting value mode display la

mp

The above (5) value is displayed as a load setting value or return value (fin

al load value).

(15)

Start lamp

This lamp lights up when press ram is at top dead center (origin). (Synchro

nized with upper limit signal)

(16)

Hold lamp

This lamp lights up when press hold is input. (Press hold in this instruction

means the lamp is emitted during the press ram is descending and not emitt

ed at the bottom dead end)

Warning: In “Safety one process,” after input of hold signal, press ram

continuously descends even if start signal is turned off. In order to prevent

danger, it is necessary to adjust (dog position so that) the hold signal alway

s enters just before upper die contacts with the product.

(17)

Sensor CUT lamp

This lamp lights up when measurement start signal is activated. When the la

mp is lights up, load measurement is not carried out. If this is not wired,

measurement starts simultaneously when start button is pushed.

Contact point a: This is closed when the signal is activated.

(18)

Sensor END lamp

This lamp lights up when measurement completion signal is activated. This

is used in modes 5, 6 or 7. Input signal for terminal b specs.

Contact point b: This is opened when signal is activated.

(19)

Ten keys

These are used when upper/lower limit comparison value, setting load value

or pressurizing time is registered or changed.

(20)

Reset key

This is used for canceling or display initializing when registering or changin

g is carried out.

Canceling of prohibition of press starting after judging NG, clearing displaye

d value and initializing judgment result signal are carried out. (When this b

utton is pushed when press process ends, return value switches to setting va

lue)

Loading...

Loading...