- 10 -

When installed to the air-press (For the case of QC press)

1.How to make die matching (inching operation)?

(1)Switch switching operation function of press controller to “Die matching” position.

(2)Inching valve should be closed.

(3)Press ram descends while press start signal is input and ram stops when press start signal is off.

(4)Ram ascends when inching valve opens.

(5)Repeat the above operations (3) and (4) and carry out die setting. It is easy to operate if regulator or speed controller is

appropriately throttled.

Fine adjustment for jig matching: In the state that ram stops when inching operation is carried out, ram slowly descends

when air pressure is reduced with regulator and ram ascends when air pressure is

boosted. Die matching is easily carried out utilizing this.

(6)When die matching is completed, inching valve should be full open.

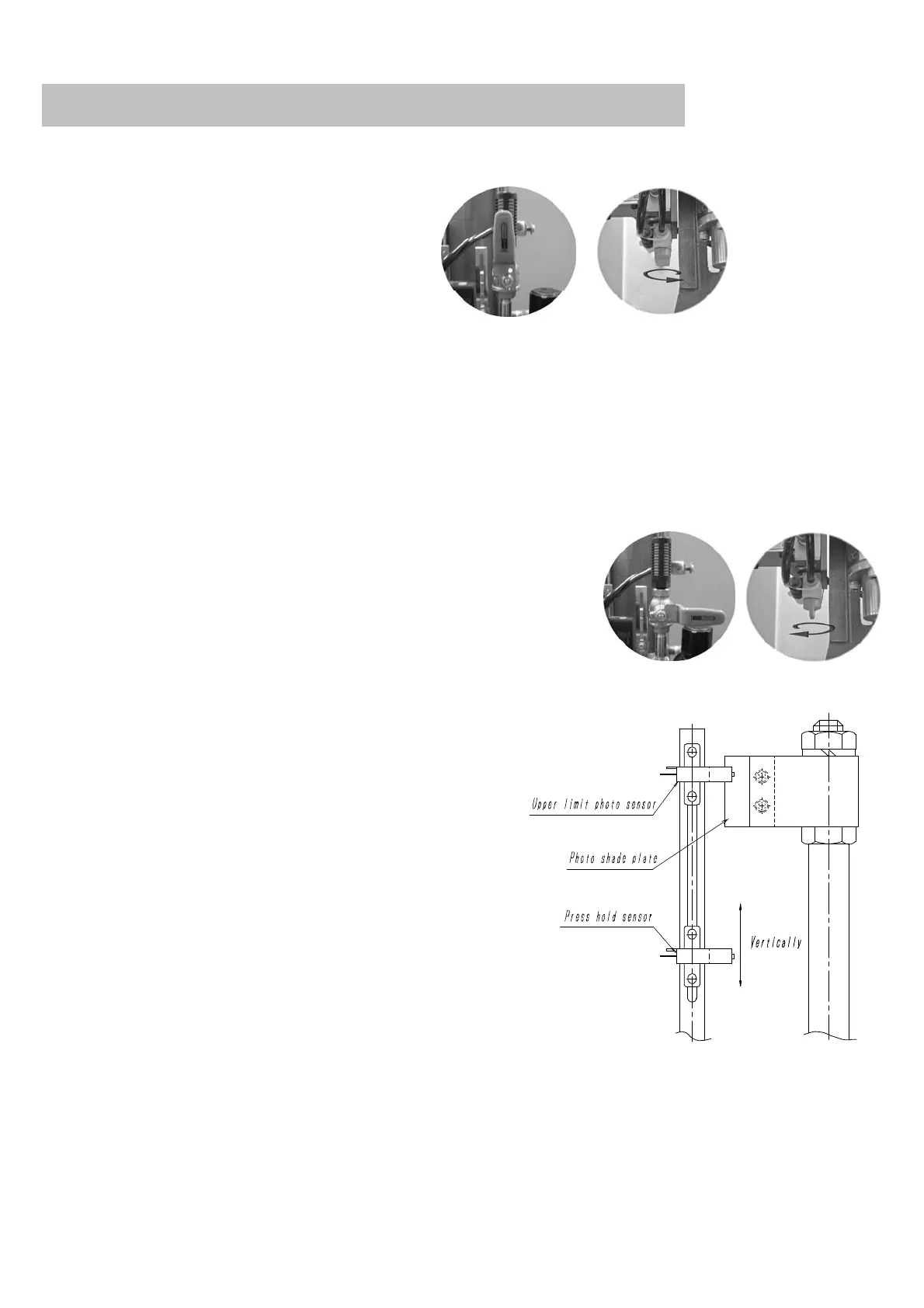

2.Press hold sensor adjustment

(1)Switch for press controller switching operation function

should be switched to “Die matching.” Place product which

is not press-fitted on die (jig) and make upper die slowly

descend with inching operation and stop just before

contacting with the product.

(2)In order to make press hold sensor being operated state by

shade plate at this position, loosen two bolts fixing press

hold sensor switch to adjust while sliding switch vertically.

(3)It is possible to verify operation of press hold sensor using

hold lamp on the face of press controller panel. (Lamp lights

up when switch is operated)

For safety, press hold sensor position should be set to the

lowest possible position.

Loading...

Loading...