/

.,/

Cv AS

O-RI N

SEMBL

G

Y

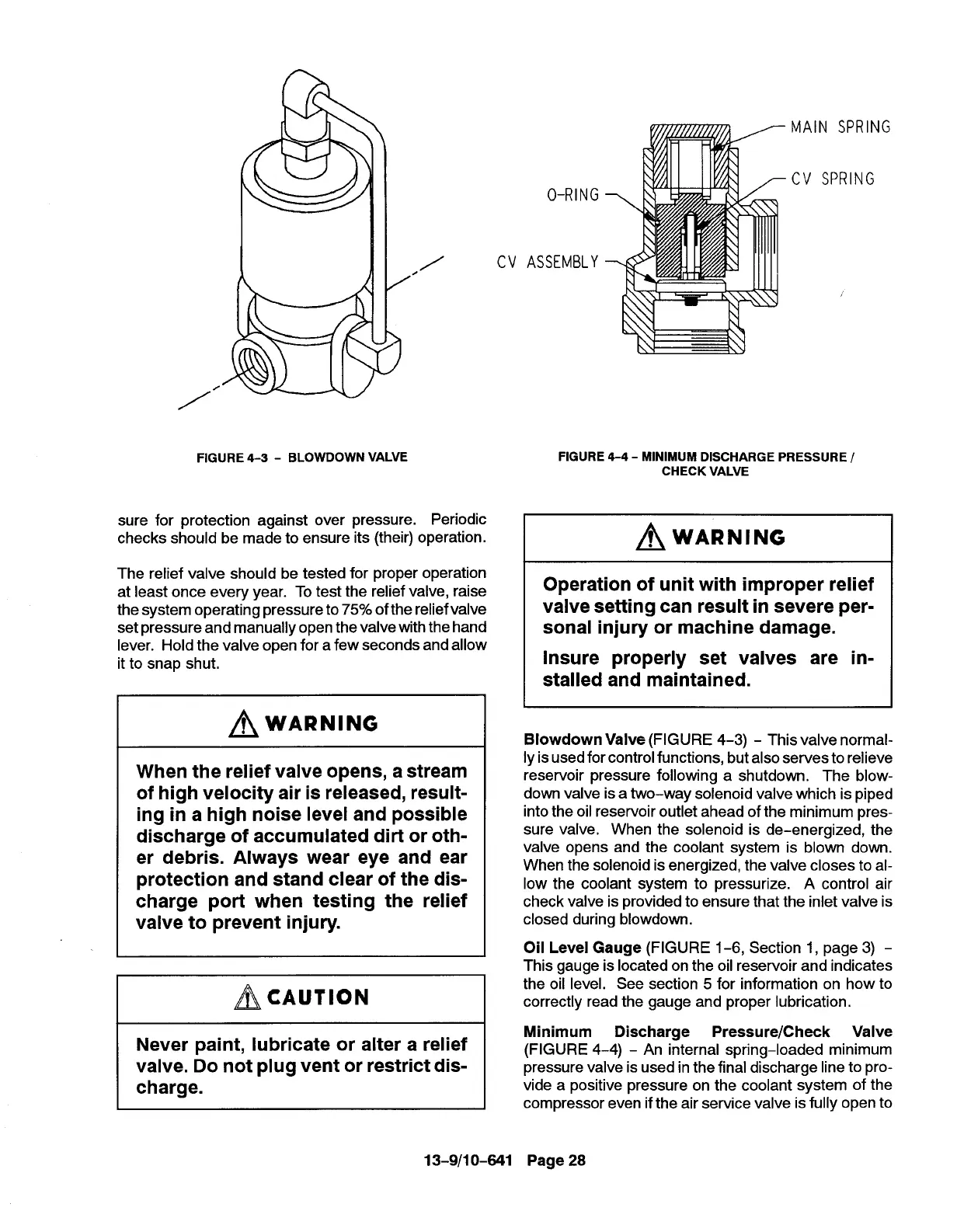

FIGURE 4-3- BLOWDOWN VALVE

sure for protection against over pressure. Periodic

checks should be made to ensure its (their) operation.

The relief valve should be tested for proper operation

at least once every year. To test the relief valve, raise

the system operating pressure to 75% ofthe relief valve

set pressure and manually open the valve with the hand

lever. Hold the valve open for a few seconds and allow

it to snap shut,

wARNING

When the relief valve opens, a stream

of high velocity air is released, result-

ing in a high noise level and possible

discharge of accumulated dirt or oth-

er debris. Always wear eye and ear

protection and stand clear of the dis-

charge port when testing the relief

valve to prevent injury.

I

~CAUTION

I

I

Never paint, lubricate or alter a relief

I

I valve. Do not plug vent or restrict dis- I

I

charge.

I

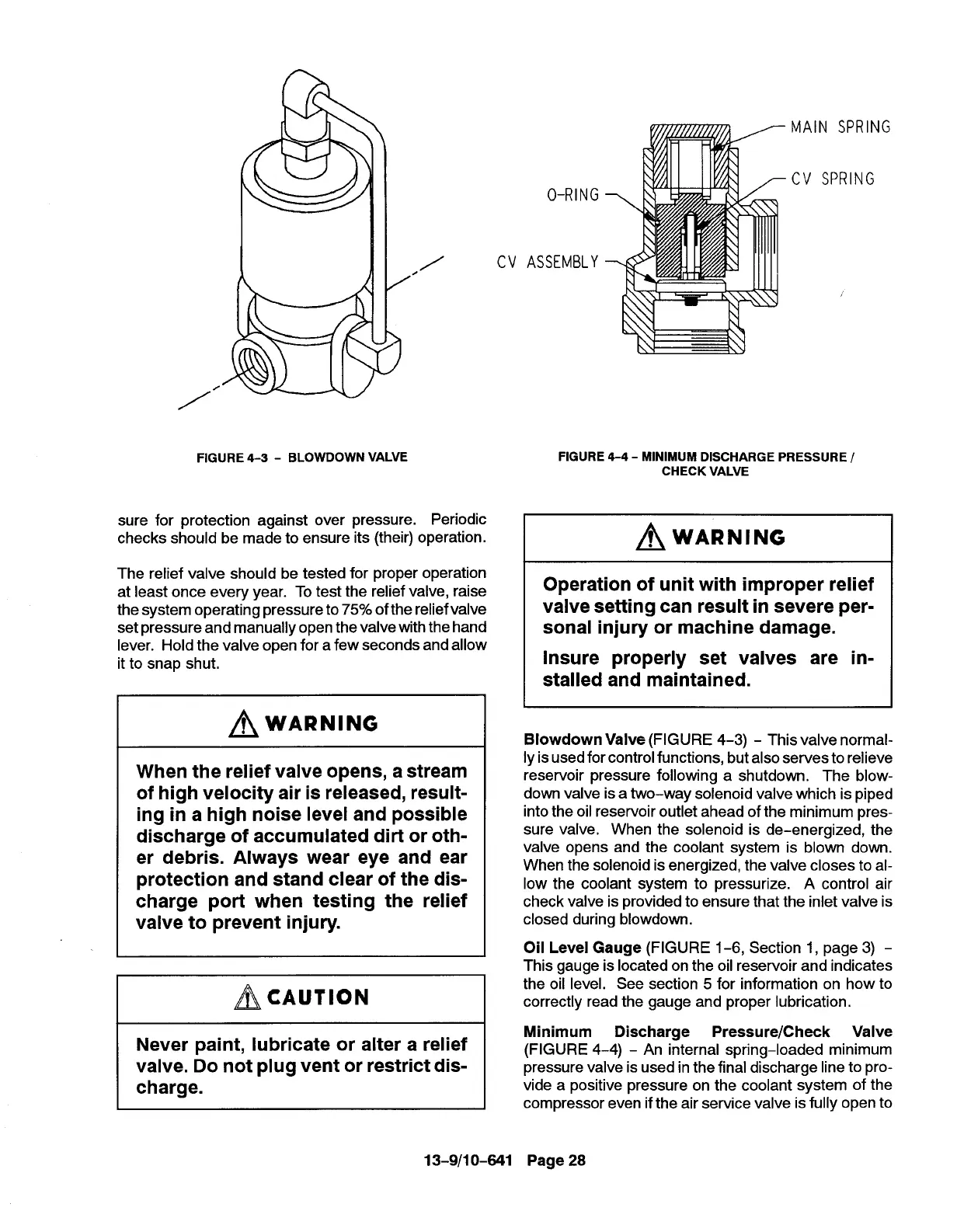

MAIN SPRING

CV SPRING

/

FIGURE 4-4- MINIMUM DISCHARGE PRESSURE /

CHECK VALVE

~WARNING

Operation of unit with improper relief

valve setting can result in severe per-

sonal injury or machine damage.

Insure properly set valves are in-

stalled and maintained.

Blowdown Valve (FIGURE 4-3) - This valve normal-

ly is used for control functions, but also serves to relieve

reservoir pressure following a shutdown. The blow-

down valve is a two-way solenoid valve which is piped

into the oil reservoir outlet ahead of the minimum pres-

sure valve, When the solenoid is de-energized, the

valve opens and the coolant system is blown down.

When the solenoid is energized, the valve closes to al-

low the coolant system to pressurize. A control air

check valve is provided to ensure that the inlet valve is

closed during blowdown.

Oil Level Gauge (FIGURE 1-6, Section 1, page 3) -

This gauge is located on the oil reservoir and indicates

the oil level. See section 5 for information on how to

correctly read the gauge and proper lubrication.

Minimum

Discharge Pressure/Check Valve

(FIGURE 4-4) - An internal spring-loaded minimum

pressure valve is used in the final discharge line to pro-

vide a positive pressure on the coolant system of the

compressor even if the air service valve is fully open to

13-9/1

0-641 Page 28

Loading...

Loading...