When operating conditions are severe (very dusty, high

humidity, etc.), it will be necessary to change the oil

‘ more frequently. Operating conditions and the appear-

ance of the drained oil must be surveyed and the oil

change intervals planned accordingly by the user.

Gardner Denver@ offers a free oil analysis program

with the AEON ~ lubricants and we recommend a sam-

ple be sent in at 100 hours on a new unit,

DRAINING AND CLEANING OIL SYSTEM

~DANGER

Air/oil under pressure will cause

severe personal injury or death. Shut

down compressor, relieve system of

all pressure, disconnect, tag and

lockout power supply to the starter

before removing valves, caps, plugs,

fittings, bolts, and filters.

~DANGER

Compressor, air/oil reservoir, separa-

tion chamber and all piping and tub-

ing may beat high temperature during

and after operation.

Always drain the complete system, Draining when the

oil is

hot will help to prevent varnish deposit< and carry

away impurities.

To drain the system, use one of the following methods:

1.

if the unit is not elevated high enough to use the

oil reservoir drain line to drain oil, a small hand,

electric or air operated pump should be

used to

2.

3.

drain reservoir through the oil filler opening or from

the drain valve.

Ifthe unit is elevated so that the oil reservoir drain

can be used, empty the oil reservoir through the

drain valve to a suitable container or sump.

If the drained oil and/or the oil filter element are

contaminated with dirt, flush the entire system:

reservoir, oil cooler, mixing valve and lines, in-

spect the oil separator elements for dirt accumula-

tion; replace if necessary. If a varnish deposit ex-

ists, contact the factory for recommendations

for removal of the deposit and prevention of var-

nish.

FILLING

OIL RESERVOIR

~DANGER

Air/oil under pressure will cause

severe personal injury or death. Shut

down compressor, relieve system of

all pressure, disconnect, tag and

lockout power supply to the starter

before removing valves, caps, plugs,

fittings, bolts, and filters.

1.

Be sure the unit is completely off and that no air

pressure is in the oil reservoir.

2.

Disconnect, tag and lockout the power supply to

the starter.

3.

Wipe away all dirt around the oil filler plug.

4.

Remove the oil filler plug and add oil as required

to return the oil level to the center of the green

range on the gauge.

5.

Install the oil filler plug and operate the unit for

about a minute allowing oil to fill all areas of the

system. Check for leaks.

6.

Shut down unit, allowing the oil to settle, and be

certain all pressure is relieved.

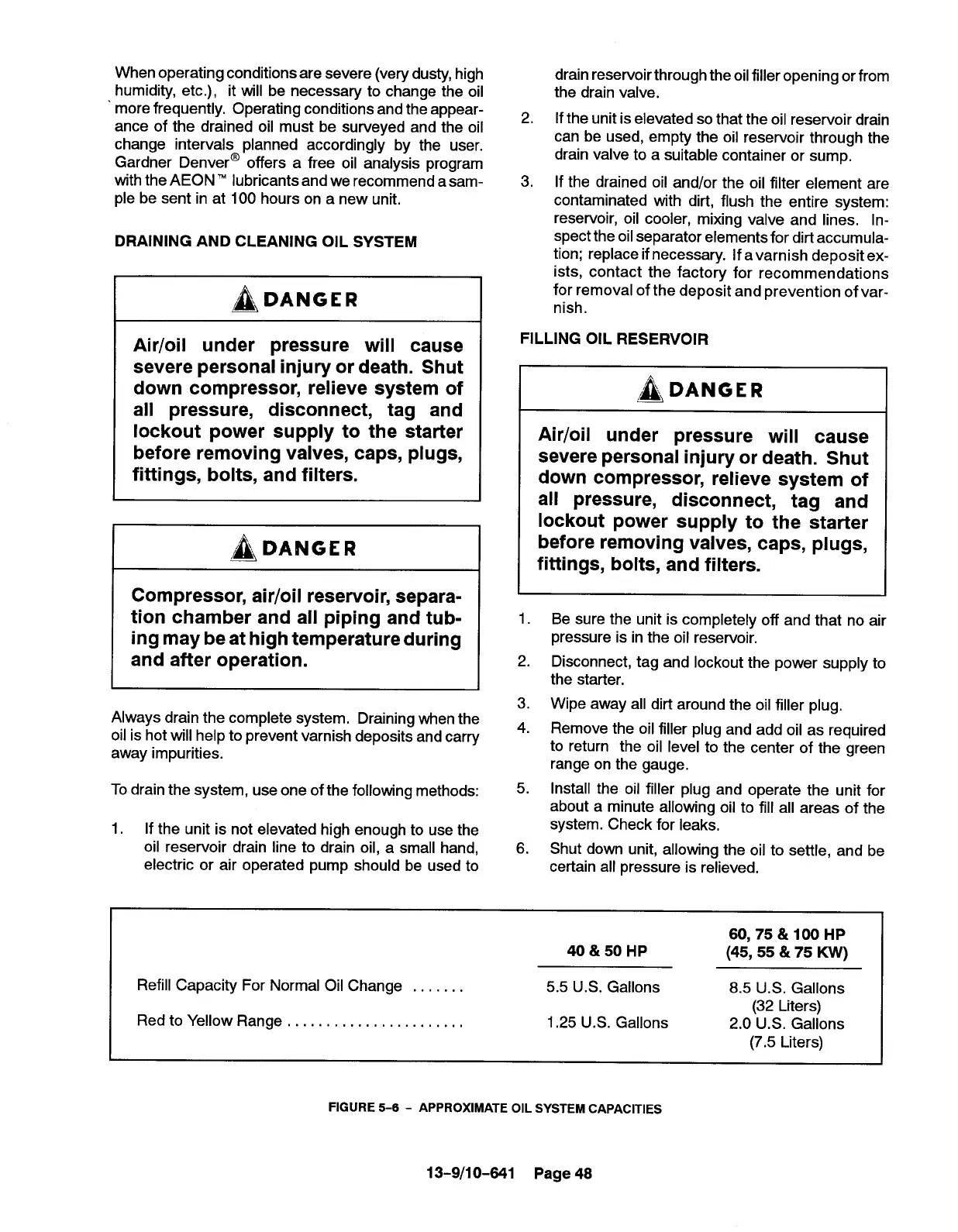

60, 75& 100 HP

40& 50 HP

(45, 55& 75 Kw)

Refill Capacity For Normal Oil Change . . . . . . . 5.5 U.S. Gallons 8.5 U.S. Gallons

(32 Liters)

Redto Yellow Range . . . . . . . . . . . . . . . . . . . . . . . 1.25 U.S. Gallons

2.0 U.S. Gallons

(7.5 Liters)

FIGURE 5-6- APPROXIMATE OIL SYSTEM CAPACITIES

13-9/10-641 Page 48

Loading...

Loading...