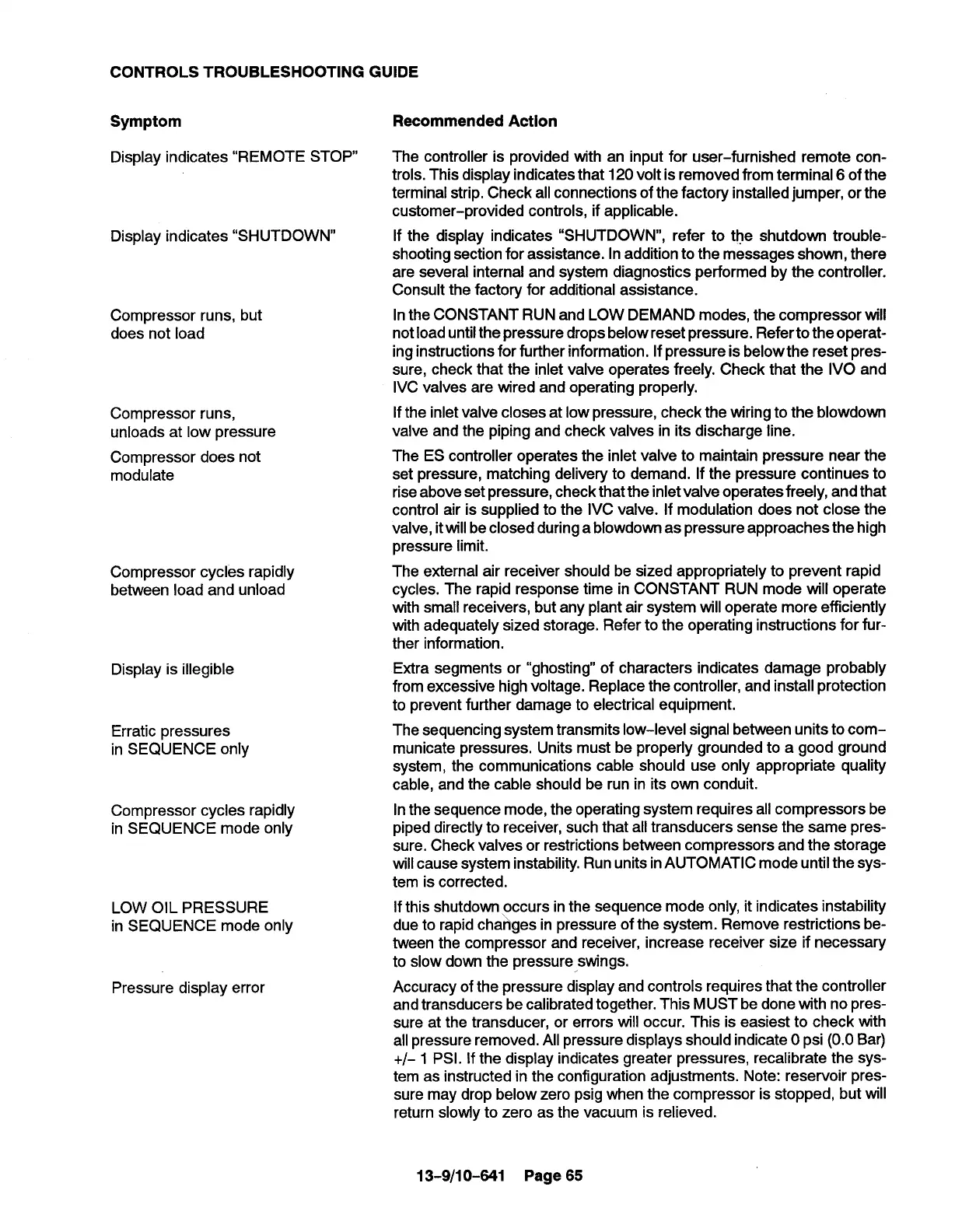

CONTROLS TROUBLESHOOTING GUIDE

Symptom

Display indicates “REMOTE STOP

Display indicates “SHUTDOWN”

Compressor runs, but

does not load

Compressor runs,

unloads at low pressure

Compressor does not

modulate

Compressor cycles rapidly

between load and unload

Display is illegible

Erratic pressures

in SEQUENCE only

Compressor cycles rapidly

in SEQUENCE mode only

LOW OIL PRESSURE

in SEQUENCE mode only

Pressure display error

Recommended Action

The controller is provided with an input for user-furnished remote con-

trols. This display indicates that 120 volt is removed from terminal 6 of the

terminal strip. Check all connections of the factory installed jumper, or the

customer-provided controls, if applicable.

If the display indicates “SHUTDOWN”, refer to the shutdown trouble-

shooting section for assistance. In addition to the messages shown, there

are several internal and system diagnostics performed by the controller.

Consult the factory for additional assistance.

In the CONSTANT RUN and LOW DEMAND modes, the compressor will

not load untilthe pressure drops below reset pressure. Refer to the operat-

ing instructions for further information, If pressure is below the reset pres-

sure, check that the inlet valve operates freely. Check that the IVO and

IVC valves are wired and operating properly.

If the inlet valve closes at low pressure, check the wiring to the blowdown

valve and the piping and check valves in its discharge line.

The ES controller operates the inlet valve to maintain pressure near the

set pressure, matching delivery to demand. If the pressure continues to

rise above set pressure, check that the inlet valve operates freely, and that

control air is supplied to the IVC valve. If modulation does not close the

valve, itwill be closed during a blowdown as pressure approaches the high

pressure limit.

The external air receiver should be sized appropriately to prevent rapid

cycles. The rapid response time in CONSTANT RUN mode will operate

with small receivers, but any plant air system will operate more efficiently

with adequately sized storage. Refer to the operating instructions for fur-

ther information.

Extra segments or “ghosting” of characters indicates damage probably

from excessive high voltage. Replace the controller, and install protection

to prevent further damage to electrical equipment,

The sequencing system transmits low-level signal between units to com-

municate pressures. Units must be properly grounded to a good ground

system, the communications cable should use only appropriate quality

cable, and the cable should be run in its own conduit.

In the sequence mode, the operating system requires all compressors be

piped directly to receiver, such that all transducers sense the same pres-

sure. Check valves or restrictions between compressors and the storage

will cause system instability. Run units inAUTOMATIC mode until the sys-

tem is corrected.

If this shutdown occurs in the sequence mode only, it indicates instability

due to rapid changes in pressure of the system. Remove restrictions be-

tween the compressor and receiver, increase receiver size if necessary

to slow down the pressure,swings.

Accuracy of the pressure display and controls requires that the controller

and transducers be calibrated together. This MUST be done with no pres-

sure at the transducer, or errors will

occur. This is easiest to check with

all pressure removed. All pressure displays should indicate Opsi (0.0 Bar)

+/- 1 PSI. If the display indicates greater pressures, recalibrate the sys-

tem as instructed in the configuration adjustments. Note: reservoir pres-

sure may drop below zero psig when the compressor is stopped, but will

return slowty to zero as the vacuum is relieved.

13-9/10-641 Page 65

Loading...

Loading...