PUR

MINIMUM

PRESSURE

)

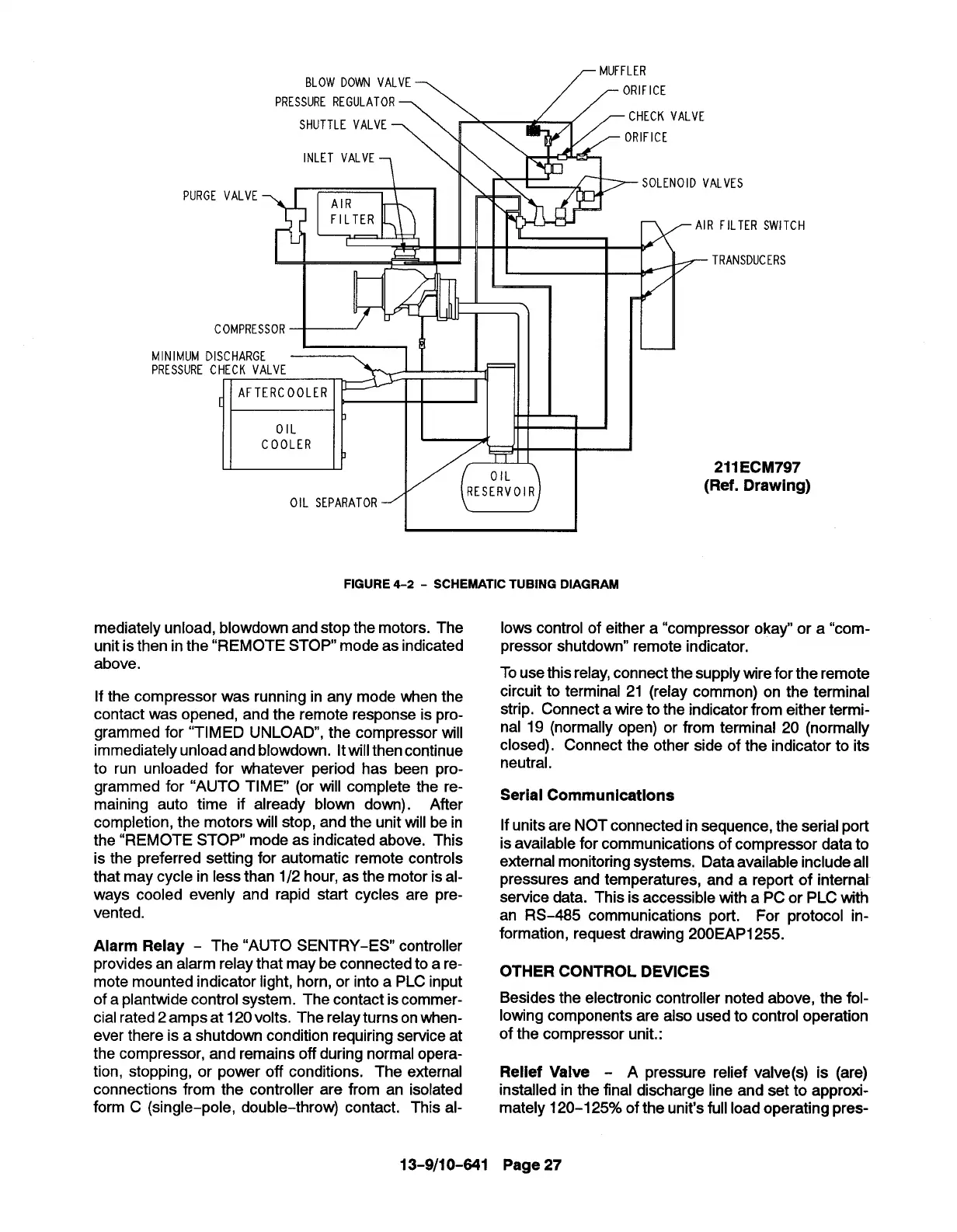

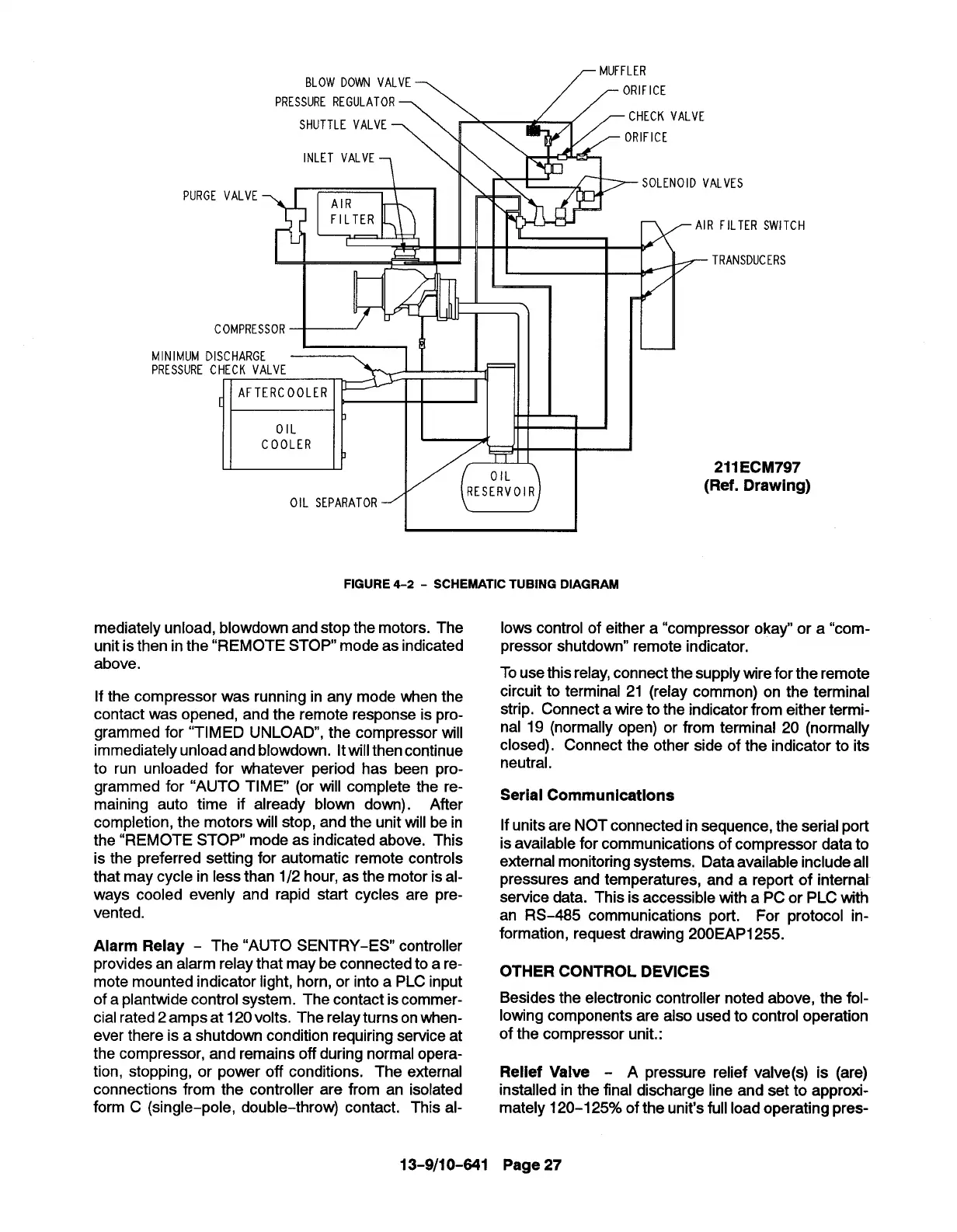

FIGURE 4-2- SCHEMATIC TUBING DIAGRAM

mediately unload, blowdown and stop the motors. The

unit is then in the “REMOTE STOP mode as indicated

above.

If the compressor was running in any mode when the

contact was opened, and the remote response is pro-

grammed for “TIMED UNLOAD, the compressor will

immediately unload and blowdown. It willthen continue

to run unloaded for whatever period has been pro-

grammed for “AUTO TIME (or will complete the re-

maining auto time if already blown down). After

completion, the motors will stop, and the unit will be in

the “REMOTE STOP mode as indicated above, This

is the preferred setting for automatic remote controls

that may cycle in less than 1/2 hour, as the motor is al-

ways cooled evenly and rapid start cycles are pre-

vented.

Alarm Relay - The “AUTO SENTRY-ES controller

provides an alarm relay that maybe connected to a re-

mote mounted indicator light, horn, or into a PLC input

of a plantwide control system. The contact is commer-

cial rated 2 amps at 120 volts. The relay turns on when-

ever there is a shutdown condition requiring service at

the compressor, and remains off during normal opera-

tion, stopping, or power off conditions. The external

connections from the controller are from an isolated

form C (single-pole, double-throw) contact. This al-

13-9/10-641

lows control of either a “compressor okay” or a “com-

pressor shutdown” remote indicator,

To use this relay, connect the supply wire for the remote

circuit to terminal 21 (relay common) on the terminal

strip. Connect a wire to the indicator from either termi-

nal 19 (normally open) or from terminal 20 (normally

closed). Connect the other side of the indicator to its

neutral.

Serial Communications

If units are NOT connected in sequence, the serial port

is available for communications of compressor data to

external monitoring systems. Data available include all

pressures and temperatures, and a report of internat

service data. This is accessible with a PC or PLC with

an RS-485 communications port. For protocol in-

formation, request drawing 200 EAP1255.

OTHER CONTROL DEVICES

Besides the electronic controller noted above, the fol-

lowing components are also used to control operation

of the compressor unit.:

Relief Valve - A pressure relief valve(s) is (are)

installed in the final discharge line and set to approxi-

mately 120-1 25% of the unit’s full load operating pres-

Page 27

Loading...

Loading...