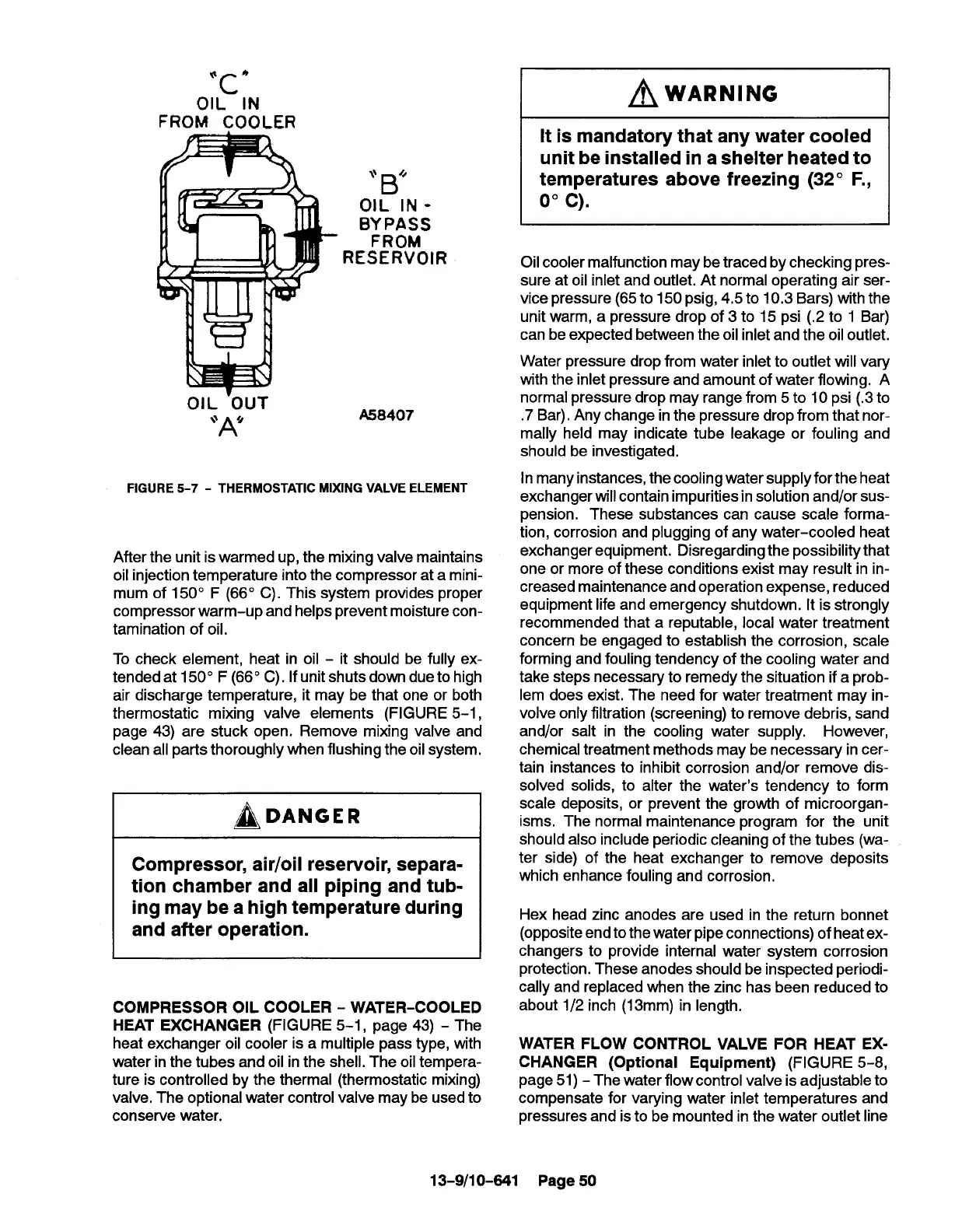

OIL”lN

~wARNiNG

FROM COOLER

“B’

OIL lN -

B;:~~S

RESERVOIR

OIL ‘OUT

“A’

A58407

FIGURE 5-7 - THERMOSTATIC MIXING VALVE ELEMENT

After the unit is warmed up, the mixing valve maintains

oil injection temperature into the compressor at a mini-

mum of 150° F (66° C). This system provides proper

compressor warm-up and helps prevent moisture con-

tamination of oil.

To check element, heat in oil - it should be fully ex-

tended at 150° F (66° C). If unit shuts down due to high

air discharge temperature, it may be that one or both

thermostatic mixing valve elements (FIGURE 5-1,

page 43) are stuck open. Remove mixing valve and

clean all parts thoroughly when flushing the oil system.

~DANGER

Compressor, air/oil reservoir, separa-

tion chamber and all piping and tub-

ing may be a high temperature during

and after operation.

COMPRESSOR OIL COOLER - WATER-COOLED

HEAT EXCHANGER (FIGURE 5-1, page 43) - The

heat exchanger oil cooler is a multiple pass type, with

water in the tubes and oil in the shell. The oil tempera-

ture is controlled by the thermal (thermostatic mixing)

valve. The optional water control valve may be used to

conserve water.

It is mandatory that any water cooled

unit be installed in a shelter heated to

temperatures above freezing (32° F.,

0°c).

Oil cooler malfunction may be traced by checking pres-

sure at oil inlet and outlet. At normal operating air ser-

vice pressure (65 to 150 psig, 4,5 to 10.3 Bars) with the

unit warm, a pressure drop of 3 to 15 psi (.2 to 1 Bar)

can be expected between the oil inlet and the oil outlet.

Water pressure drop from water inlet to outlet will vary

with the inlet pressure and amount of water flowing. A

normal pressure drop may range from 5 to 10 psi (.3 to

.7 Bar). Any change in the pressure drop from that nor-

mally held may indicate tube leakage or fouling and

should be investigated.

In many instances, the cooling water supply for the heat

exchanger will contain impurities in solution and/or sus-

pension. These substances can cause scale forma-

tion, corrosion and plugging of any water-cooled heat

exchanger equipment. Disregarding the possibility that

one or more of these conditions exist may result in in-

creased maintenance and operation expense, reduced

equipment life and emergency shutdown. It is strongly

recommended that a reputable, local water treatment

concern be engaged to establish the corrosion, scale

forming and fouling tendency of the cooling water and

take steps necessary to remedy the situation if a prob-

lem does exist. The need for water treatment may in-

volve only filtration (screening) to remove debris, sand

and/or salt in the cooling water supply. However,

chemical treatment methods may be necessary in cer-

tain instances to inhibit corrosion and/or remove dis-

solved solids, to alter the water’s tendency to form

scale deposits, or prevent the growth of microorgan-

isms, The normal maintenance program for the unit

should also include periodic cleaning of the tubes (wa-

ter side) of the heat exchanger to remove deposits

which enhance fouling and corrosion,

Hex head zinc anodes are used in the return bonnet

(opposite endtothe water pipe connections) of heat ex-

changers to provide internal water system corrosion

protection. These anodes should be inspected periodi-

cally and replaced when the zinc has been reduced to

about 1/2 inch (13mm) in length.

WATER FLOW CONTROL VALVE FOR HEAT EX-

CHANGER (Optional Equipment) (FIGURE 5-8,

page 51) - The water flow control valve is adjustable to

compensate for varying water inlet temperatures and

pressures and is to be mounted in the water outlet line

13-9/10-641 Page 50

Loading...

Loading...