S47183-e 01/2008 Design and specifications are subject to change without notice 40

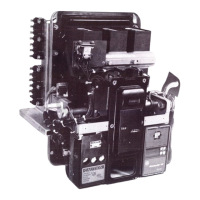

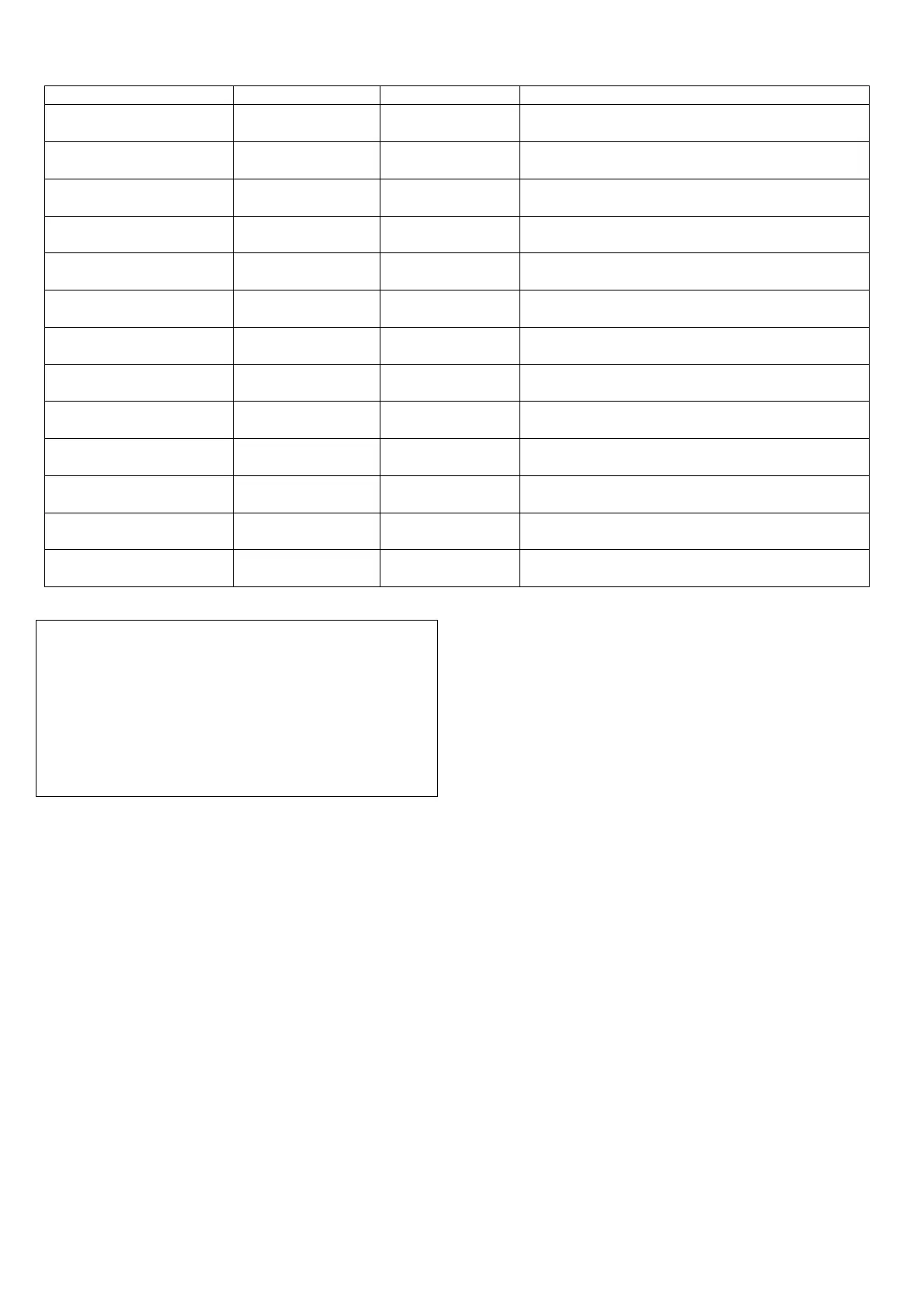

6.2 List of maintenance works

TYPE OF THE WORK BY WHOM WHEN REQUIRED RECOMMENDATIONS

A. Arc chute changing Customer.

Trained technician

As a result of the

inspection C

B. Pre-arcing contact and

arc runners changing

Customer.

Trained technician

As a result of the

inspection C

Replace complete pre-arcing set .

C. Protective walls chang-

ing

Customer.

Trained technician

As a result of the

inspection C

D. Adjustment of the con-

tacts

GE.

Service engineer

As a result of the

inspection C

Only in case, when replacement of the pre-arcing

contact results with incorrect gaps. See point 6.1.5.

E. Replacement of the

control board

Customer.

Trained technician

As a result of the

inspection B,E

F. Adjustment of the

mechanism

GE.

Service engineer

As a result of the

inspection B,E

G. Flexband or fix contact

changing

GE.

Service engineer

As a result of the

inspection C,E

H. Mechanism changing GE.

Service engineer

As a result of the

inspection B,E

I. Dumper(s) changing GE.

Service engineer

As a result of the

inspection E

Replace upper and lower dumper at the same

time.

J. Trip unit changing & ad-

justment

GE.

Service engineer

As a result of the

inspection B,E

K. Auxiliary switches ad-

justment and changing

Customer.

Trained technician

As a result of the

inspection B,E

In case of wrong signalization of the switches, ad-

justment might be necessary.

L. Drive changing GE.

Service engineer

As a result of the

inspection B,E

M. Accessories changing GE.

Service engineer

As a result of the

inspection B,E

Table 4

Required tools:

• Cleaning tissue

• Pocket lamp

• Hand lever

• Hexagon wrench SW 4, SW 5, SW 6

• Screw wrench SW 10, SW 13

• Small and medium screwdriver

• Pliers

• Wire cutter

• File

• Steel brush

6.2.1 Maintenance of contact system (after 11/2003)

Pay attention to the warnings, Section 1 !

This section is valid for breakers manufactured after

11/2003.

This section refers to maintenance works A, B, C from

Table 4.

A) Remove the arc chute

• [Fig. 49]. Loosen the clamping screws (3) and (4), using

SW 5 hexagon wrench and take off the arch chute (1)

from the adapter (2).

B) Remove the arc chute adapter

• [Fig. 48]. For dismantling the arc chute adapter loosen

and pull out the four upright screws (1) using SW5 tool.

Pay attention that no screws or washers fall inside the

breaker !

• [Fig. 48]. Draw aside and lift off both parings of

adapter (2). Then pull out two protective walls (3).

C) Changing the protective walls, arc runners and arcing

contacts

• [Fig. 48]. Pull out two protective walls (3).

• [Fig. 50]. Loosen screws (6a) with tool (SW4) and take

out front wall (6).

• [Fig. 50]. Loosen screw (5a) with tool (SW5) and take

out the front arc runner (5).

• [Fig. 50]. Take out the back arc runner (4) by loosen

two screws (4a) with tool (SW5). Don’t remove the pro-

tective cap (4b).

• [Fig. 50]. Loosen and take out screw (7) inclusive lock-

ing plate (8). Don’t split up screw and locking plate!

• [Fig. 50]. Pull out axis (9). Pull out pre-arcing contact

(10) and put in new pre-arcing contact.

• [Fig. 50]. Put in axis (9) and protect it by the locking

plate (8). Tighten screw (7) with torque of 10 Nm

[88lbf*in].

• [Fig. 50]. Install front-arc runner (5) and back-arc run-

ner (4). Tighten it using torque of 10 Nm [88lbf*in].

• [Fig. 50]. Install front wall (6) and adjust it by position-

ing the protective wall. Tighten with torque of 10 Nm

[88lbf*in].

• [Fig. 48]. Put in two protective walls (3).

Loading...

Loading...