S47183-e 01/2008 Design and specifications are subject to change without notice 52

7.3 Glossary

- A -

a-release – see Shunt trip device;

Activating magnet – see Closing drive;

Anti-pumping device – see SU control unit;

Arc runners – (also: arc probes; arc horns). Provide safe arc

leading into the arc chute. There are two arc runners mounted

in Gerapid breaker, front and back.

Arcing contact – see pre-arcing contact;

Auxiliary switch – (also: auxiliary contact; make/break contact;

a-/b-contact). Switch containing up to 10 auxiliary contacts, me-

chanically operated by the mechanism of the breaker in case of

switching operation. Auxiliary switch block is mounted in lower

compartment of the control box. Every contact h can be NO or

NC configured by appropriate wiring.

-C-

Closing drive – (also: activating magnet; closing solenoid; sole-

noid drive). Big black solenoid coil, mounted at the front of the

breaker below the control box. It is used for electrically, re-

motely closing of the main contacts. Power consumption is up

to 2.6kW. Closing time is ~150ms.

Closing operation – (also: switching ON; CLOSE operation). It is

operation, by which the breaker is brought from the OPEN posi-

tion to the CLOSED position. This is realizing by means of closing

drive or hand lever.

Closing solenoid - see Closing drive;

Control terminals – (also: control sockets/plugs). Fully insulated

sockets at the front cover of control box. Intended to use for

connection the auxiliary control circuits.

-E-

ED coil – (also: electr-dynamic coil). An impulse coil, actuating

element of ED tripping device, mounted on the base, under the

movable arm.

Electro-dynamic tripping device – (also: ED tripping; impulse re-

lease). Release device, consist of actuator (ED coil) and control

circuit (NEKO PCB with C-bank). This is an optional auxiliary re-

lease, activated by high-energy impulse of current. The impulse

is shaped by internal (NEKO) or external C-bank. Opening time is

less 3ms. Time to charge capacitors is ~15sec.

-F-

Forced tripping release – (also: FTU; forced tripping device/unit).

Fully insulated, direct tripping device, mounted under the bot-

tom of the breaker’s mechanism, in the way that small pin ex-

trudes. By pushing of this pin to the top, breaker will be tripped

and open.

-H-

Hand lever – (also: manual control lever). Metal bar designed for

direct, manual operating of solenoid closing coil. Hand lever can

be used for both, closing and opening operation. It is intend to

use only during maintenance.

-M-

Main circuit – (also: mains; primary circuit; current path). All the

conductive parts of the breaker included in the circuit, which is

intend to close or open. It consists of: main terminals (upper and

lower),fix contact, flexible band and lower bus bar.

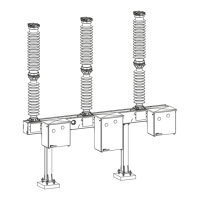

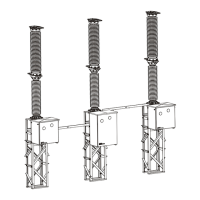

Main terminals – (also: clusters;, main connections). These are

two conductive bars provided for electrical connection to exter-

nal main circuit. Different configurations are offered.

Manual control – (also: manual operating). Close or open opera-

tion by human intervention with using of hand lever.

-N-

NEKO control PCB – (also: ED coil control unit; internal C-bank

control). Control circuit, designed as a single PCB, to supervise

the operating of electrodynamic coil. It consists of control circuit

and bank of capacitors, required to energize the ED coil. Control

circuit is supervising ED coil operations.

-O-

OCT – see Over-Current Tripping unit;

Opening operation – (also: switching OFF; OPEN operation). It’s

an operation by which the breaker is brought from the CLOSED

position to the OPEN position. This is realized by means of auxil-

iary tripping devices, OCT or hand lever.

Over-Current Tripping unit – (also: OCT). It’s an instantaneous

and direct mechanical release, tripping the breaker in case of

overloads and short circuits. It is adjustable within predeter-

mined range. Opening time depends of short circuit conditions

and shall not exceed 5ms. It does not need any imported en-

ergy, and is activated be means of magnetic energy from main

circuit.

-P-

Position indicator – (also: position indicating device). Small de-

vice mounted at the front of closing drive, which indicates

whether the breaker is in the open or close position. CLOSED

position is marked as “I”. OPEN position is marked as “O”. It is

fully mechanical device.

Pre-arcing contact – (also: pre-contact; arcing contact). Arc con-

tact on which the arc is intended to be established, to avoid of

wearing and burning of main contacts. It is mounted at the top

of flexible band. It is easy to replace and is self compensating

the contact force.

-R-

r-release – see Zero voltage release;

-S-

SEL – current measurement system, consist of sensing element

and control circuit. The sensor is an insulated tube, mounted on

the top terminal of the breaker. It’s using two Hall’s probes for

sensing the current and its direction. The proportional voltage

signal is transmitted to control circuit, placed in control box. The

SEL control PCB is an opto-isolated transducer, which generates

the standard output signals proportional to measured current.

SEL control PCB - control circuit, designed as a single PCB, for

controlling and transforming the current measurement signal

from SEL sensor.

Shunt trip device – (also: shunt release; a-release). Instantane-

ous release energized by means of voltage source. It’s directly

tripping breaker’s mechanism within 50ms. It is used for remote

OPEN operation and needs 24Vdc supply. There are available

also versions for higher control voltages, supply directly and ex-

ternally. It is installed at the bottom of mechanic block. It is con-

trol by ST PCB and releasing by external “potential free” contact.

Solenoid coil - see Closing drive;

ST control PCB – control circuit, designed as a single PCB, to su-

pervise the operating of shunt trip release.

SU control PCB – control circuit, designed as a single PCB, to

supervise the remote closing operation by means of solenoid

closing drive. It is obligatory installed in every breaker, and

placed in control box. This control circuit provides also anti-

pumping function and self cut off function, to avoid electronics

overheating during continues closing command.

Switching ON – see Closing operation;

Switching OFF – see Opening operation;

-T-

Trip-free mechanical switching device - mechanical switching

device, the moving contacts of which return to and remain in

the open position when the opening (i.e. tripping) operation is

initiated after the initiation of the closing operation, even if the

closing command is maintained. To ensure proper breaking of

the current, which may have been established, it may be neces-

sary that the contacts momentarily reach the closed position.

-U-

UVR control PCB - control circuit, designed as a single PCB, for

supervising the zero-voltage release release.

-Z-

Zero-voltage release – (also: under-voltage; UVR; r-release).

Tripping device, which permits a mechanical switching breaker

to open, when the voltage across the terminals of the UVR falls

below 3VDC. Opening time is less 50ms. It is used for remote

OPEN operation or control voltage supervision. It is installed at

the bottom of mechanic block, alternatively to ST device, and is

control by UVR PCB. Can be and released by external, “potential

free”, NO or NC contact.

Loading...

Loading...