SecoGear 24kV-27kV Air Insulation Switchgear

16

Operations and trouble shooting

Operations and trouble shooting

Before start up, the following work should be completed:

a. Check the overall condition of the switchgear and clear any

potential risk factor.

b. Check the switch,truck,isolated contactor and insulating

parts etc. by visual inspection.

c. Check the connection between earthing bus bar and

earthing conductor of the transformer substation out

side the

compartment is secure.

d. Remove all of the remaining materials, unnecessary objects

and tools inside of the compartment.

e. Wipe the compartment body and the insulation parts with

a soft cloth that should be clean and dry. Then wipe off any

remaining dust and grease.

f. Clean the surface of earthing busbar. The earthing loop

resistance should be less than 350 micro-ohms.

g. Re-install the cov

er removed during the period of installation,

wiring and commissioning.

Warning

a. Comply with all relevant safety regulations

b. Maintain circuit breakers in disconnection position

c. Remove earth wires and short wires of the hazardous areas

d. Pay attention to any abnormal situations

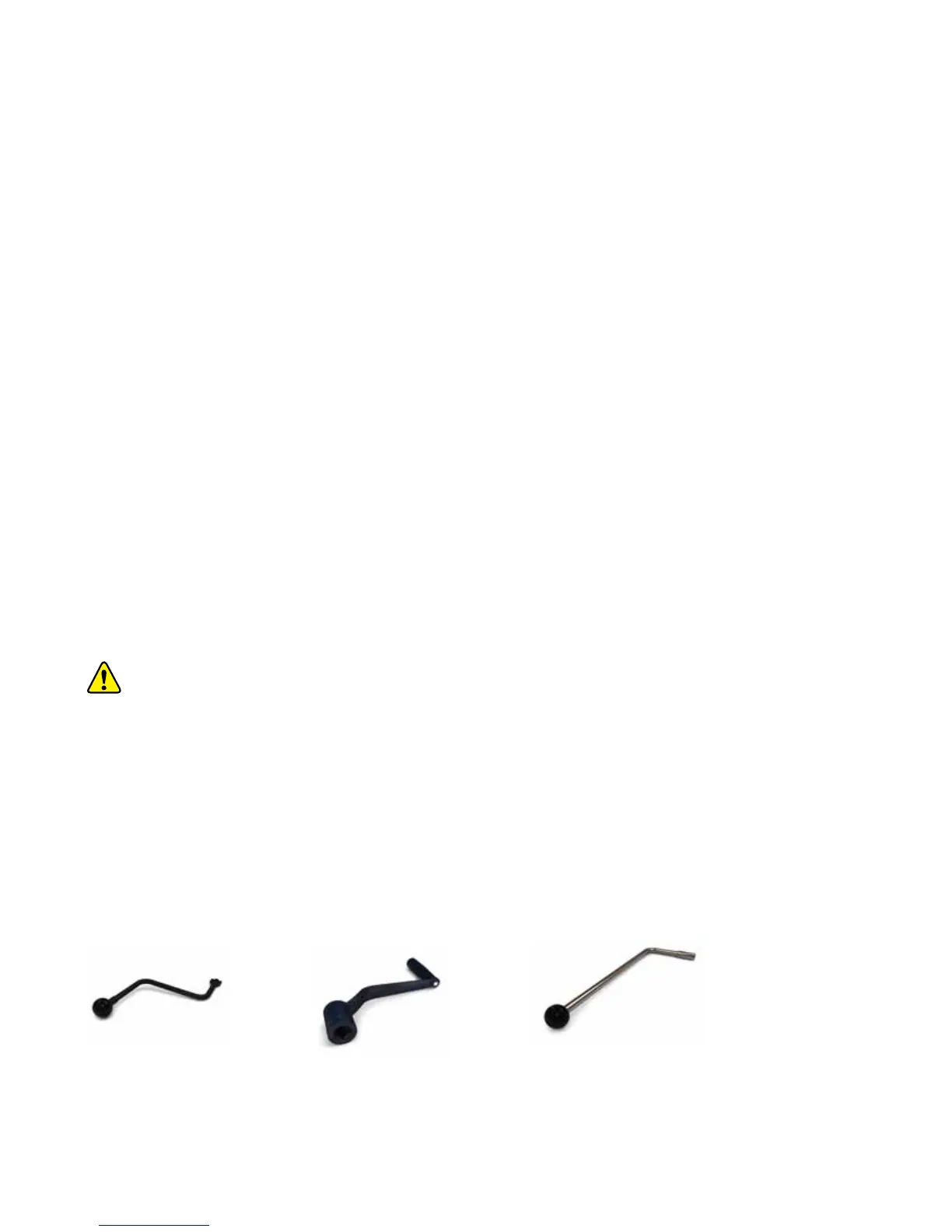

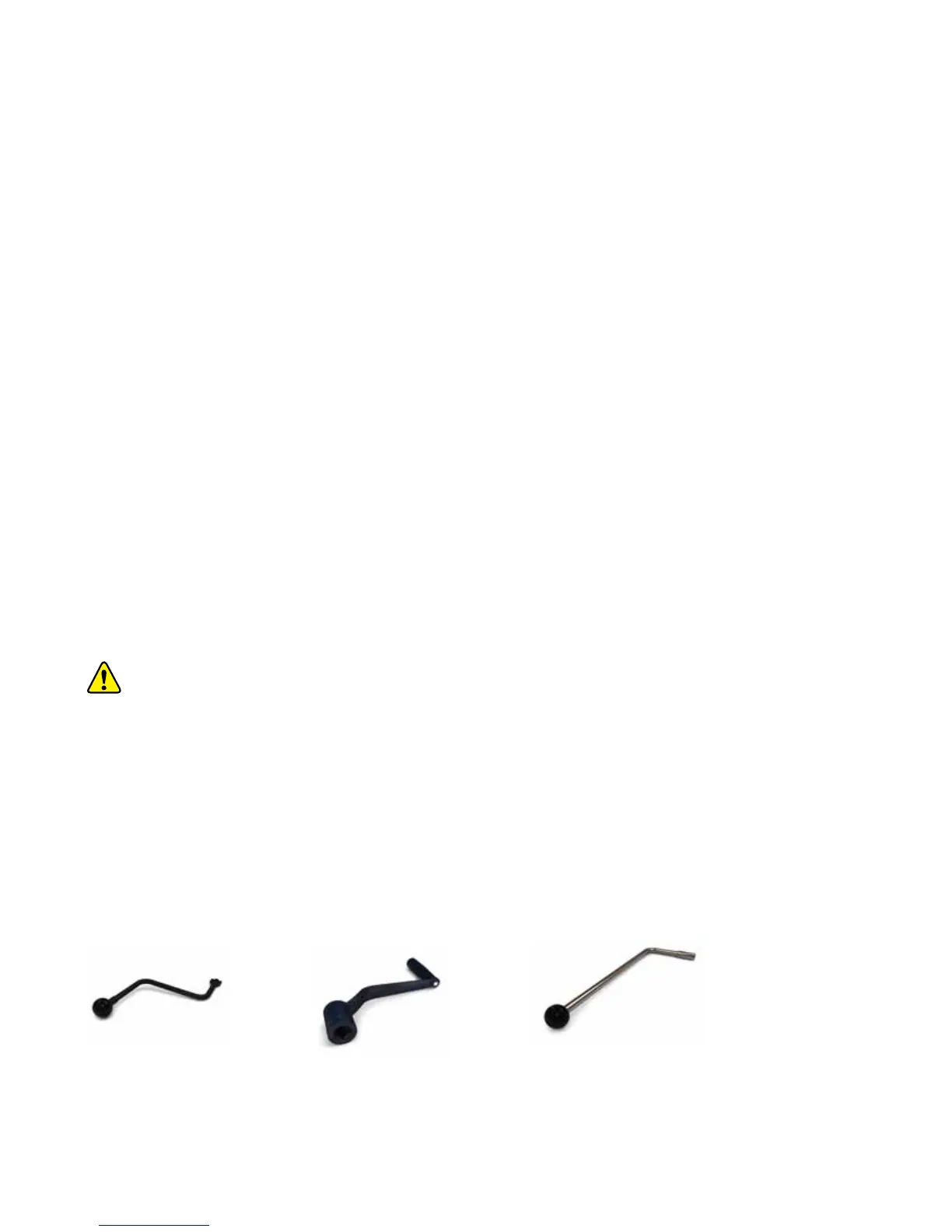

Use of hand tools

1) Gear door lock key

drawing no: 5GD.253.008

2) Rack handle for truck

drawing no: Y-002

FIG 20 : Hand Tools

h. Remove the shipping cap on the pole of the circuit breaker.

i. When

testing the power frequency withstand voltage of main

circuit, pay particular attention to sensors, cables and other

equipment during the test process.

Attention:

Read the product manual carefully when testing

the VT withstand voltage; use a test voltage of appropriate

frequency to avoid core saturation.

j. Place the Circuit Breaker on auxiliary control power.

k. Perform the operation test of the ci

rcuit breaker by manual or

electric control; observe the corresponding position indicator.

l. Check the interlocking validity, both mechanical and electrical.

m.Conductive paste can be applied on the circuit breaker

primary contacts.

3) Earthing switch operation handle

drawing no: 5GD.253.144

Loading...

Loading...