SecoGear 24kV-27kV Air Insulation Switchgear

24

Repairs

Immediate repairs are required in case of following situation emerges:

• Deteriorated insulation, discharges, flashover and breakdown

• Damaged component in the switchgear

• Any other abnormal observation which may affect safety

Inspection Items

• Check all the compartments and internal components for

dampness, rust and dirt.

• Check the tightening torques of the busbar bolted connections

on select

ed samples.

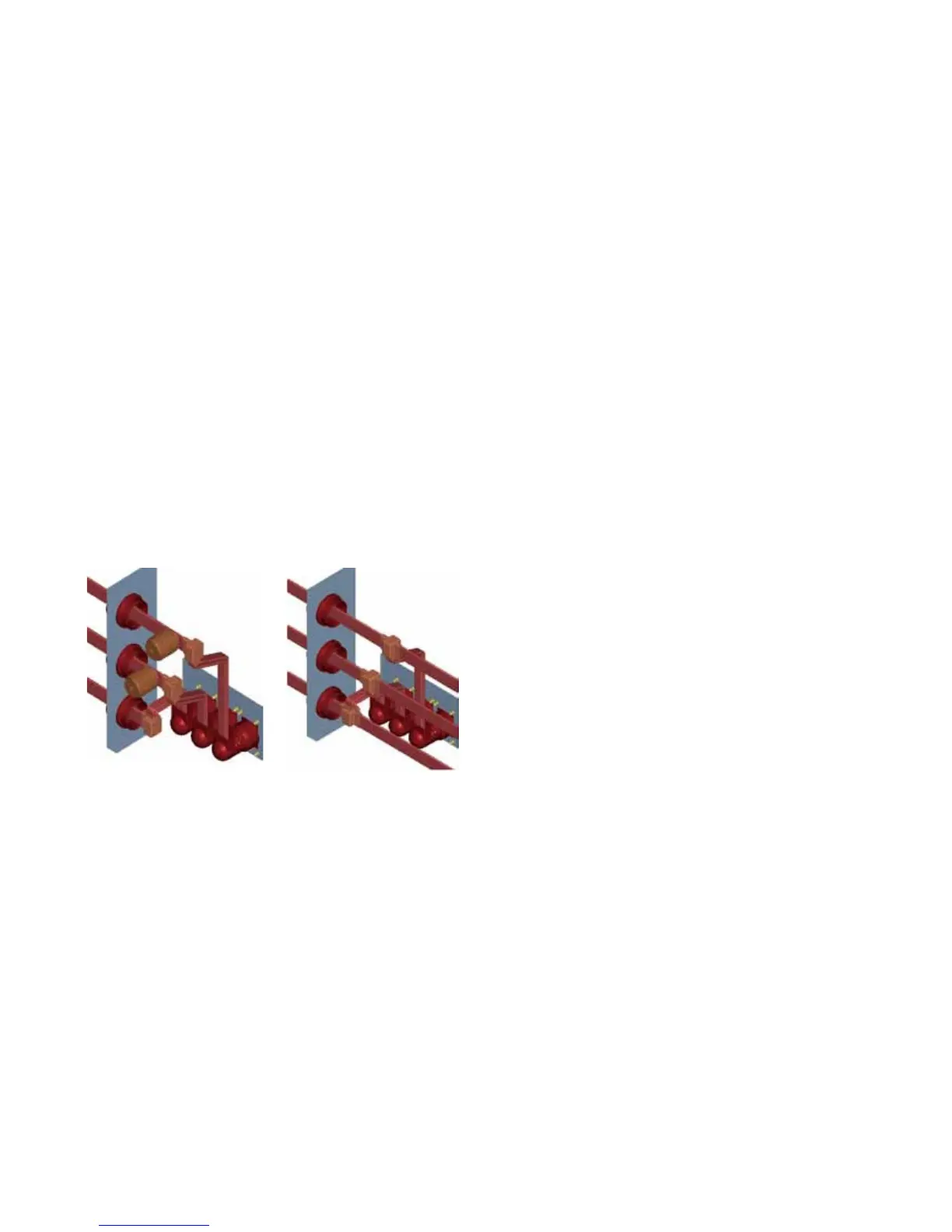

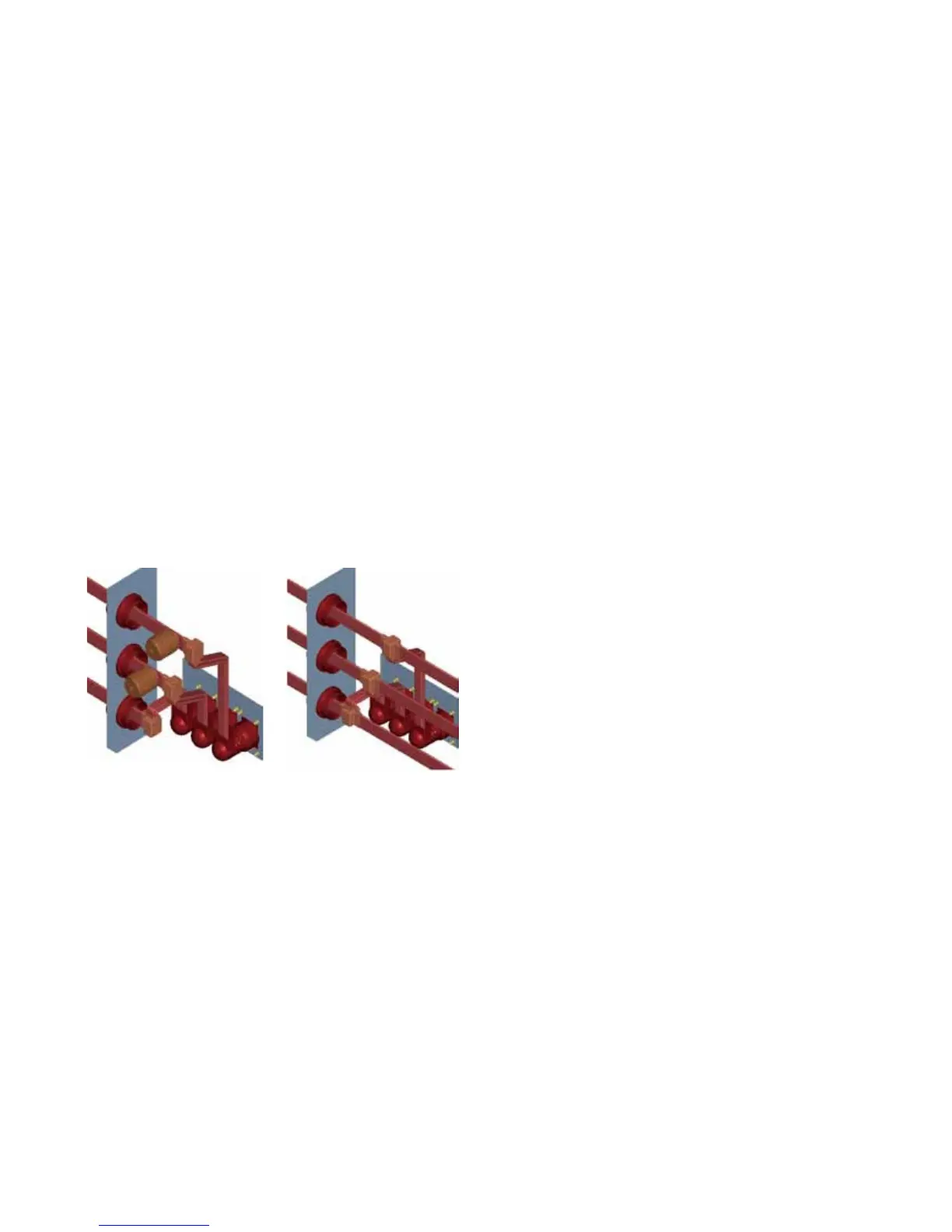

• Remove the pressure flaps on the busbar compartment and

remove the insulation shield (See fig 5/2). Check the torque is

86 N-m using a torque wrench.

Insulation

shield (for side

panel)

Insulation shield

(Middle panel)

Figure 5/2: Main busbar shield(Need to be replaced)

• Check the fixed contact including its profile for any sign of

sparking or wear-and-tear.

• Check the shutter mechanism i

n the circuit breaker

compartment.

• Check the interlocking between the circuit breaker and the

earthing switch.

• Check the bolted connection between the power cable

connectors and lugs.

• Check earthing switch operation.

• Check the interlocking between the earthing switch and the

cable compartment door.

• Check the interlocking between the circuit breaker and the

breaker compartment door.

• Check liv

e voltage indications.

• Check the heater (If installed).

Performance test

Performance test is to validate the electrical performance of the switchgear. It is recommended to be carried out together with the

scheduled service.

Performance test includes:

• Close and open the circuit break for five times, and check the circuit

• Check all the interlocking mechanism

• Electrical test including power frequency

withstand test, CT/VT ratio and the contact resistance for the circuit break

• Verify mechanical characteristics of the circuit break

Loading...

Loading...