SecoGear 24kV-27kV Air Insulation Switchgear

26

Verify the switchgear is de-energized and the safety

measures are in place.

Don't fasten the bolt initially when locking the fixed

contact, Please fasten by applying torque when the

upper branch and main busbar, lower branch and the

current transformer are fixed;

Inspection and replacement of the

fixed contact and spout bushing

It is normal to find the fixed contact surface oxidized due to

current flow an

d environmental factors during period of service.

However if the surface becomes rusty due to wet or corrosive

conditions, the fixed contact must be replaced. The spout

bushing may be replaced depending of its condition.

Clean the contact with a cotton-free paper, and apply some

pure alcohol if necessary. Brush small amount of contact

lubrication grease (DE-G51 for example) on the surface after

wipi

ng. It is important to check any abnormal condition such as

the burning marks on the spout bushing, which may be caused

by the epoxy.

• Check and replace the fixed contact

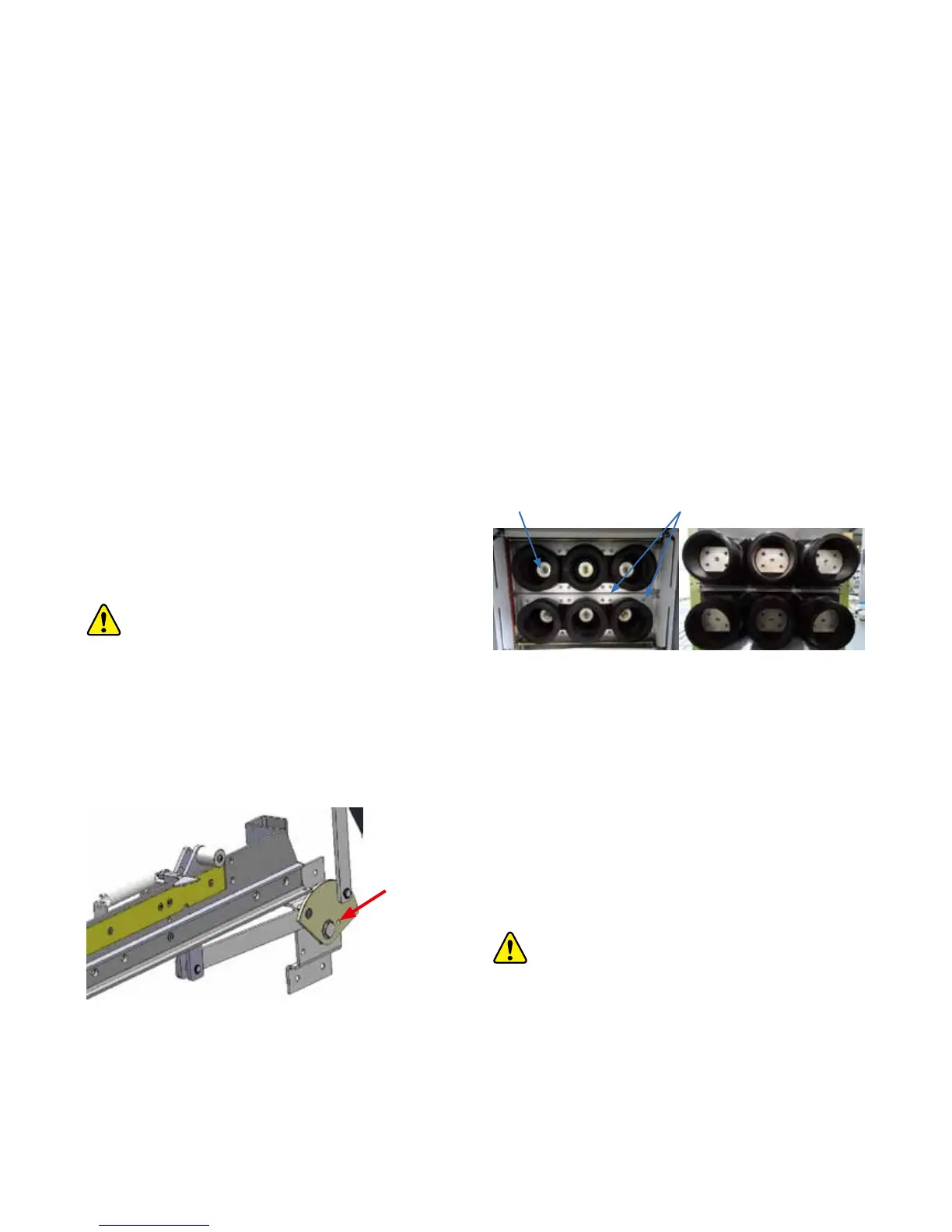

• Withdraw the circuit break . Open the shutter mechanism, and

insert two M8 bolts into the overlapping holes on the shafts

(See figure 6/2). Then the fixed contact along with the spout

bushing are visible.

Figure 6/2 : shutter mechanism

• Inspect the contacts. Replace the contact if the silver coating

on copper is worn, or the surface is corroded, damaged or

over heated.

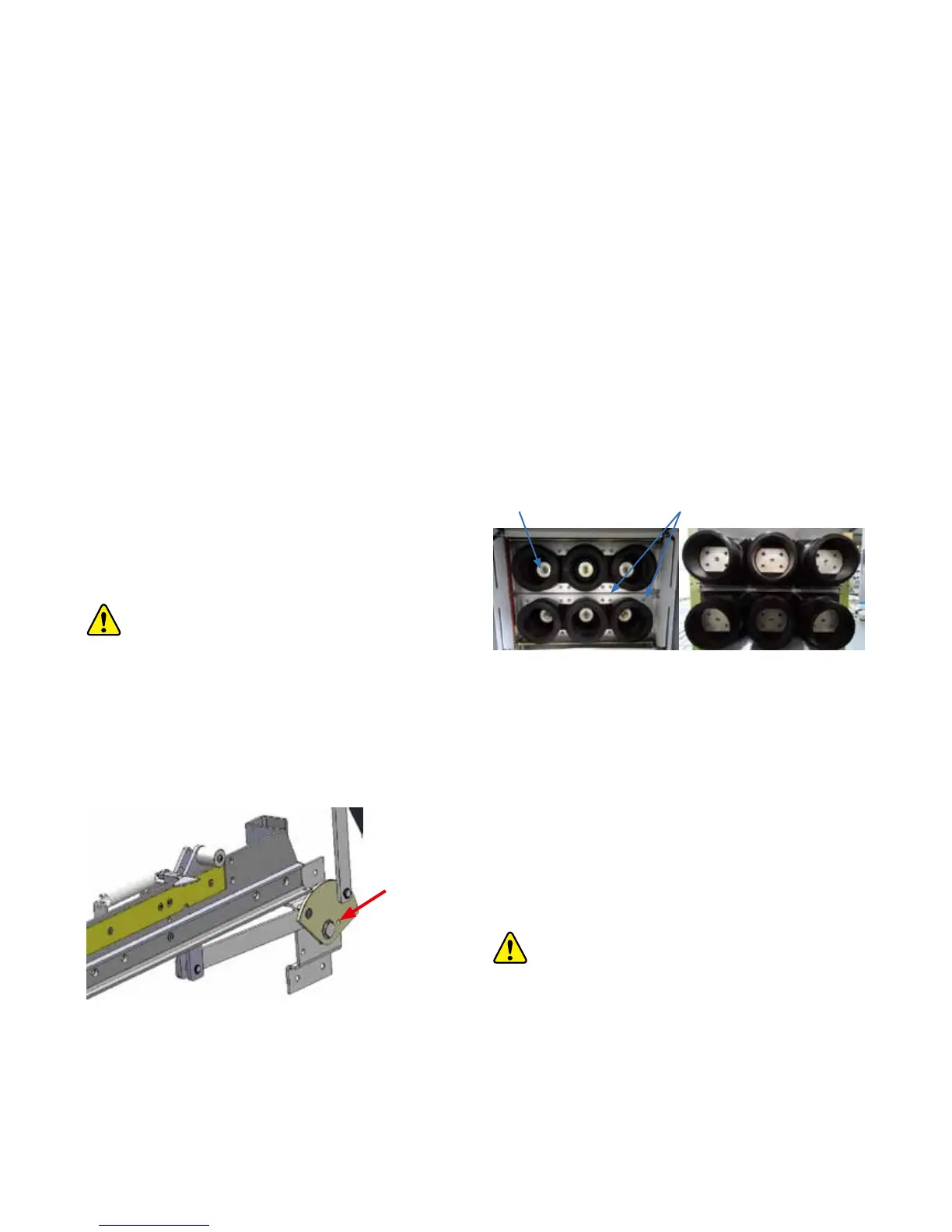

• Remove the bolts on the fixed contact, and replace the fixed

contact (see figure 6/3)

• Replace the spout bushing

• Remove the bolt at the joint of the upper branch and main

busbar

• Remove the bolt at the joint of the lower branch busba

r and

the current transformer

• Remove the center bolt of the fixed contact and then remove

the vertical connections

Figure 6/3: Fixed contact and spout bushings

• Remove four fixing screws (M12) of the spout and then the

spout can be removed (see figure 6/3)

• Replace the new spout bushing and fasten the fixing screws

(M12). Inject glass glue in the clearance between the spout

bushing and the mounting m

etal frame

• Insert the upper and lower branch busbar into the spout

bushing, and fix the fixed contact

Attention:

The torque will be different based on different sizes of

the bolt and with/without lubrication. Corresponding torques of

different bolts identified below:

Silver plating fixed contact

Front Rear

Fixing screws

Loading...

Loading...