www.geeetech.com

Page 63

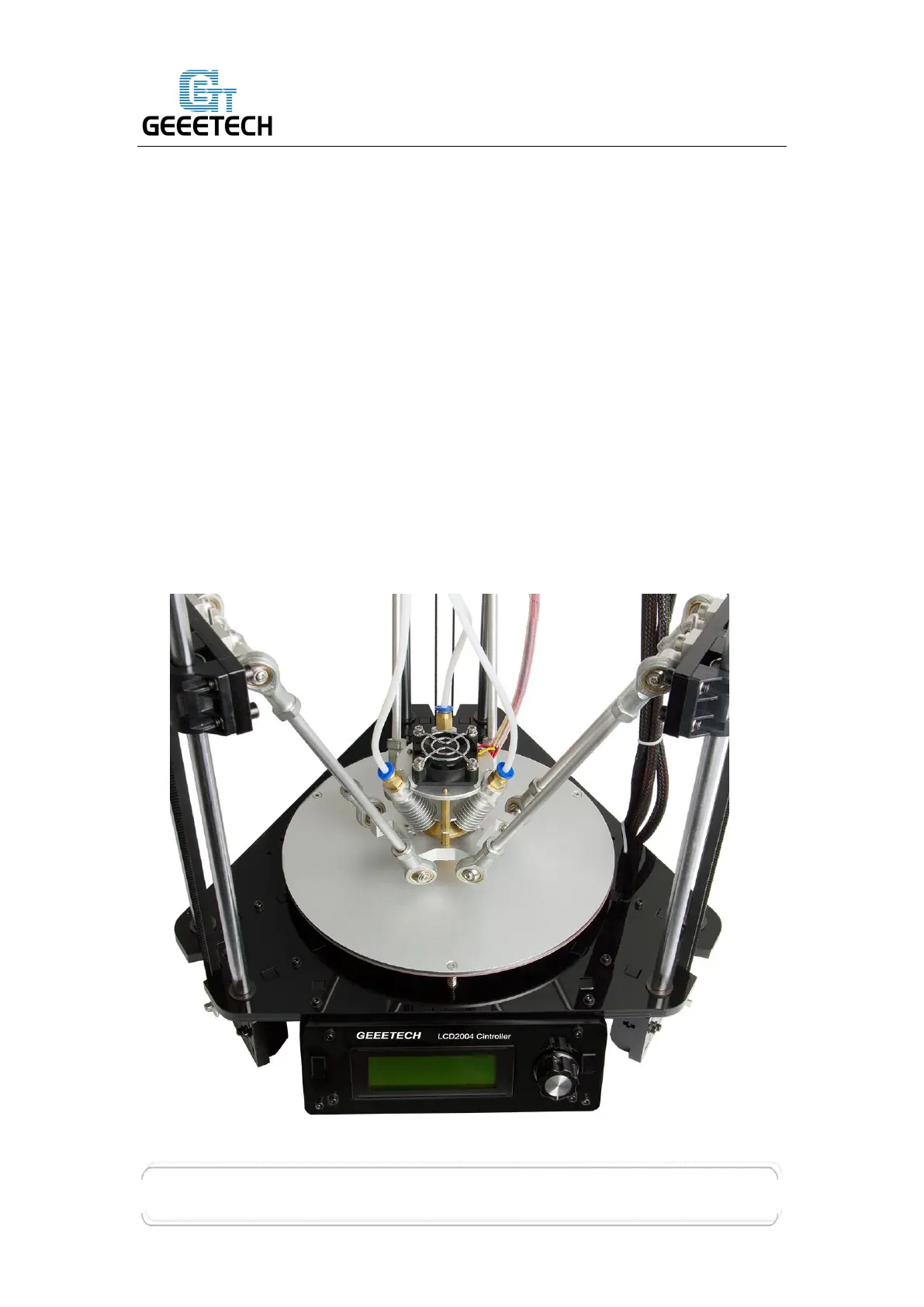

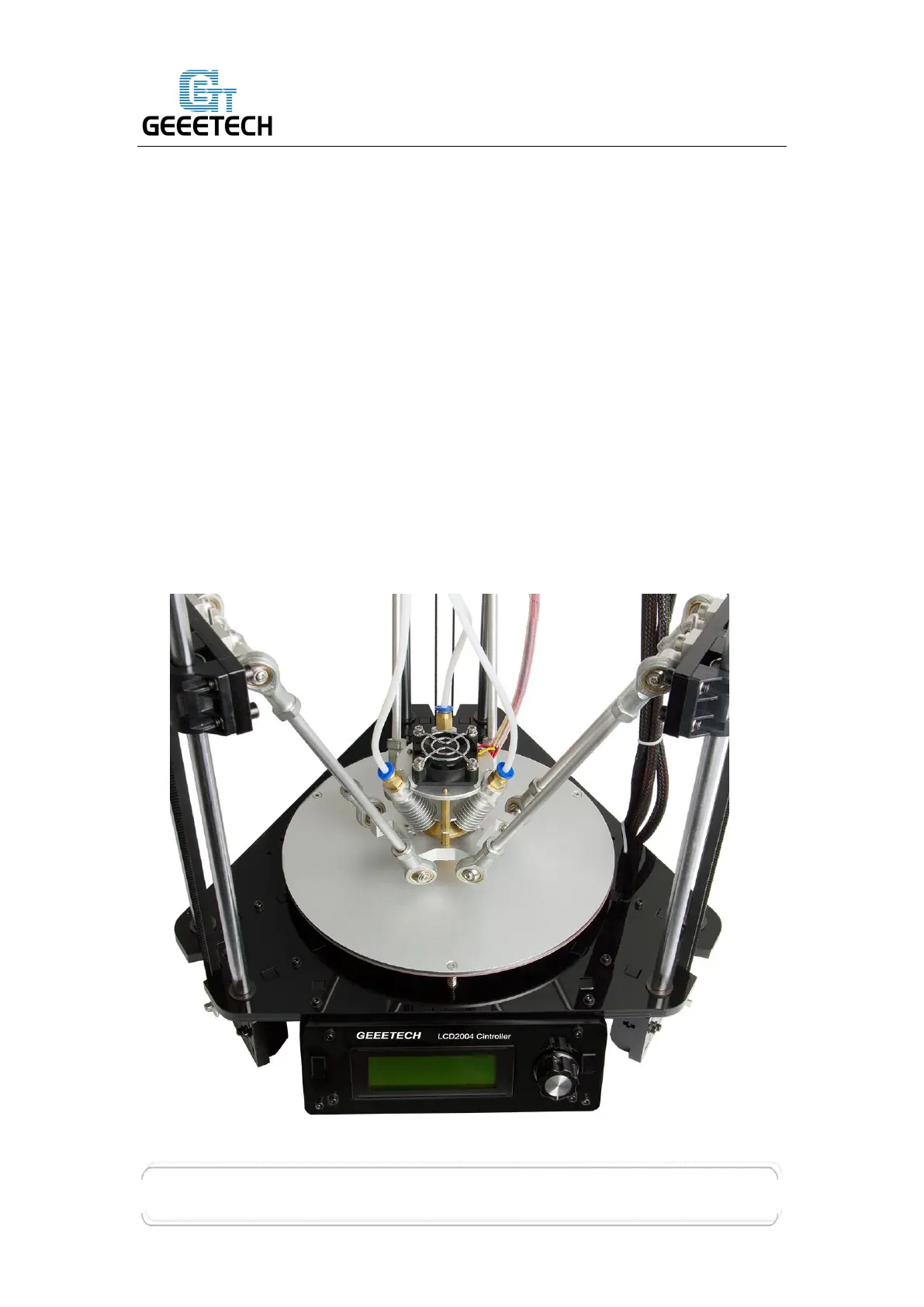

1. Before inserting the bowden tube into the HeatSinks, cut off a small piece

perpendicular the end as to make a perfect right angle cut. This is to eliminate the

gap between the tube and the hotend which will also help avoid clogging.

2. At the motor end of the bowden tube, drill the inside of the tube using an exacto

knife (or another sharp tool) in order to create a small funnel. When loading

filament this will help guide the filament into the tube. Be absolutely sure to

remove all excess from drill remaining before inserting the tube into the extruder

coupling since you do not want this residue ending up inside the hotend as it will

most likely cause clogging of your hotend.

3. Prior to applying filament you must fully insert the bowden tubes (approx. 60 mm)

into the end of the three HeatSinks. If you do not, the HeatSinks will get clogged

and the filament gets stuck!

Loading...

Loading...