Section 4 AC Diagnostic Tests

50 Diagnostic Repair Manual

Results

If Continuity was not measured in step 13 replace the

starter contactor relay. If all steps passed refer back to

flow chart.

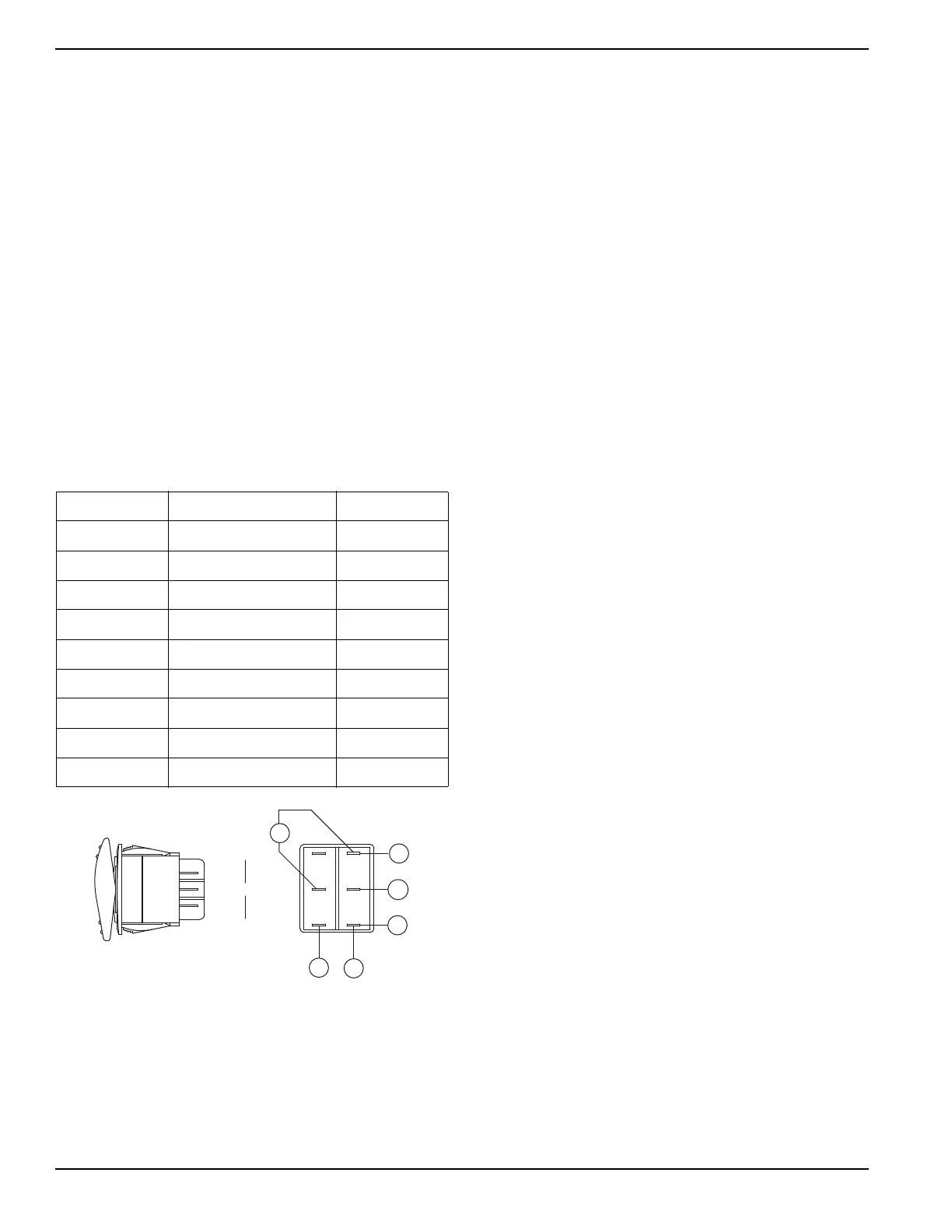

Test 27 – Check Start-Run-Stop

Switch (SW1)

Procedure

1. Set DMM to measure resistance.

2. Remove all wires from the start-run-stop switch

(SW1).

3. Use the chart below to check the condition of the

start-run-stop switch.

4. Connect one meter test lead to one terminal and

the other meter test lead to the other terminal.

5. With meter leads connected activate the switch to

START, STOP or RUN and follow the chart.

6. Connect all wires to the switch.

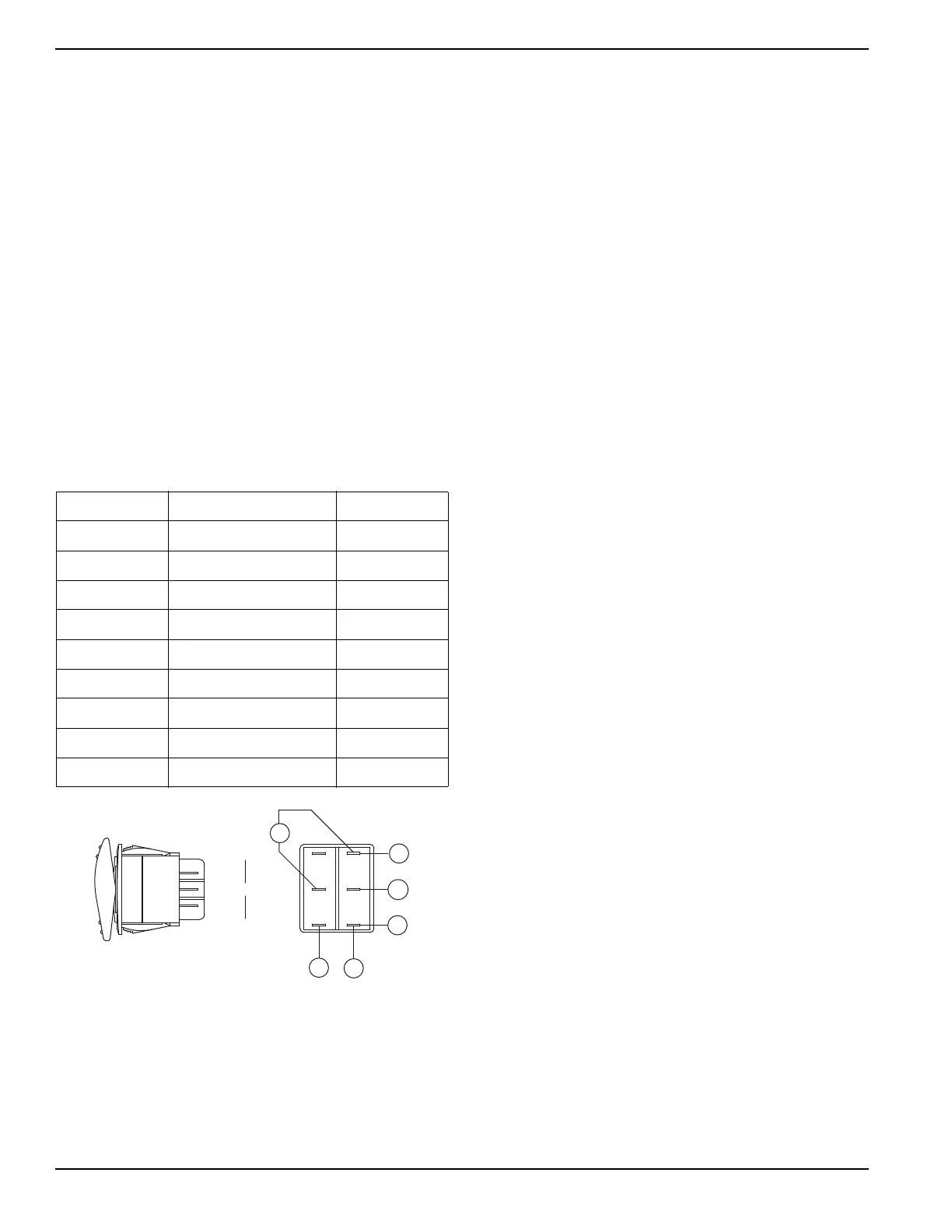

Figure 4-35. Start-Run-Stop Switch (SW1)

Results

If the switch fails any part of the test procedure replace

the switch.

Test 28 – Check Start-Run-Stop

Switch (SW1) Wiring

Procedure

1. Set DMM to measure resistance.

2. Remove wire 17 from the starter contactor relay

(SCR).

3. Connect one meter test lead to wire 17.

4. Remove wire 17 from the start-run-stop switch

(SW1).

5. Connect the other meter test lead to wire 17.

a. Continuity should be measured.

6. See Figure 4-35. Remove wire 0 from both

positions on the start-run-stop switch (SW1).

7. Connect a meter test lead to each wire 0.

a. Continuity should be measured.

8. Connect one meter test lead to one wire 0 and

connect the other meter test lead to frame ground.

a. Continuity should be measured.

9. Set DMM to measure DC voltage.

10. Remove wire 15 from the start-run-stop switch

(SW1).

11. Connect the positive meter test lead to wire 15.

12. Connect the negative meter test lead to frame

ground.

a. 12 VDC should be measured.

Results

Repair or replace any wiring that did not have continuity.

If voltage was not measured in step 12 repair wiring

between the starter contactor relay (SCR) and the start-

run-stop switch (SW1).

If all steps passed, repair or replace wire 16 between the

starter contactor (SC) and the starter contactor relay

(SCR).

Test 29 – Check Ignition Spark

Procedure

A commercially available spark tester may be used to

test the engine ignition system. One can also be

purchased from Generac Power Systems (Part No.

0C5969).

1. Disconnect a high tension lead from a spark plug.

2. Attach the high tension lead to the spark tester

terminal.

3. See Figure 4-36. Ground the spark tester clamp by

attaching to the cylinder head.

CONDITION TERMINALS RESULT

STOP 5,4 OPEN

STOP 5,6 CLOSED

STOP 2,1 OPEN

STOP 2,3 CLOSED

RUN ALL CONDITIONS OPEN

START 5,4 CLOSED

START 5,6 OPEN

START 2,1 CLOSED

START 2,3 OPEN

167

STOP

0

15

15

17

4

5

6

1

2

3

RUN

START

0

Loading...

Loading...