Section 4 AC Diagnostic Tests

Diagnostic Repair Manual 51

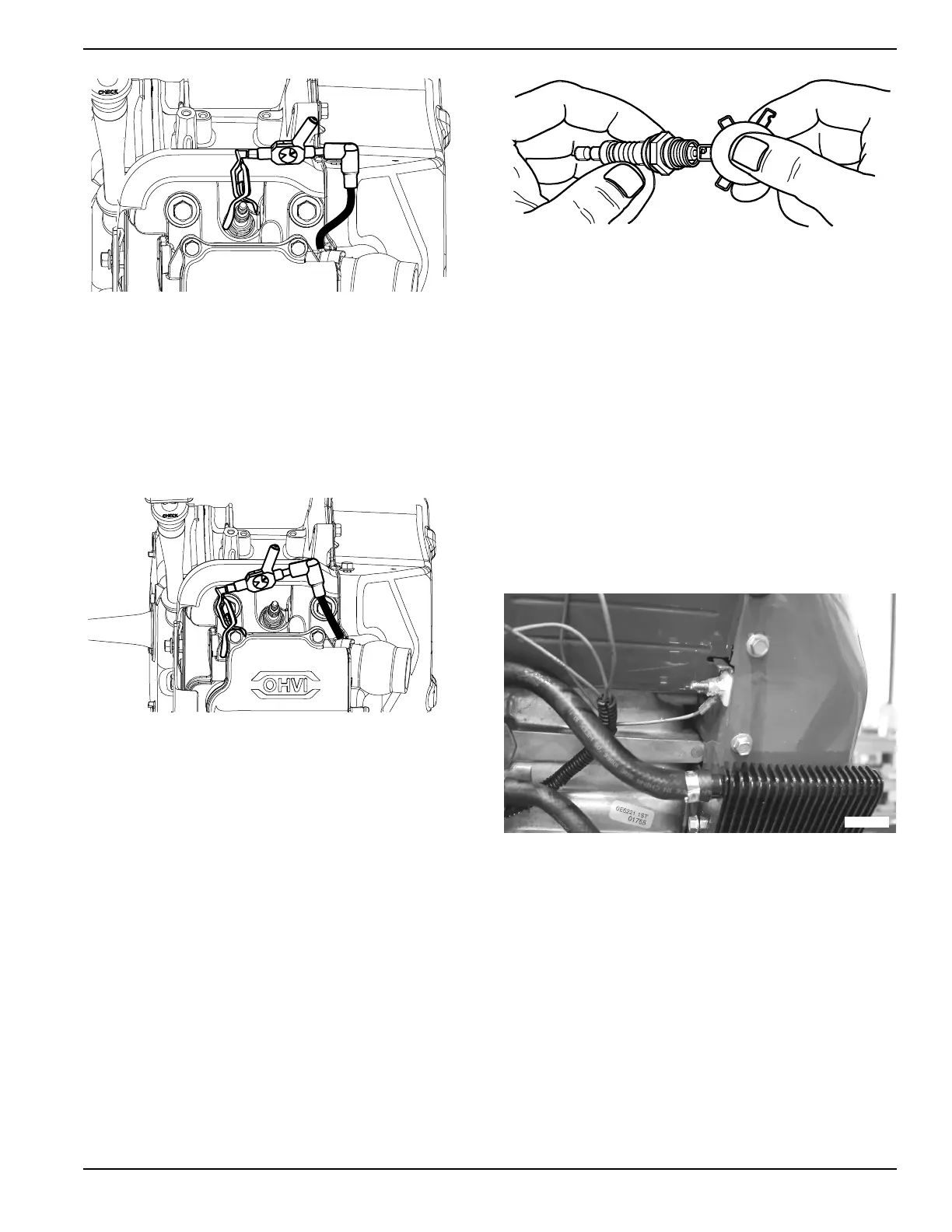

Figure 4-36. Testing Ignition System

4. Crank the engine rapidly. Engine must be cranking

at 350 rpm or more.

a. If spark jumps the tester gap, the ignition

system is working properly.

b. Repeat on remaining cylinder spark plug.

5. If spark jumps the tester gap intermittently, the

problem may be in the ignition magneto.

Figure 4-37. Checking Engine Miss

Results

Refer back to the flow chart.

Test 30 – Check Spark Plugs

Procedure

1. Remove spark plugs.

2. Clean with a commercial solvent. DO NOT BLAST

CLEAN SPARK PLUGS.

3. Replace spark plugs if badly fouled, if ceramic is

cracked, or if badly worn or damaged.

4. Set gap to 0.040 inch (1.016 mm).

5. Use a Champion RC14YC (or equivalent)

replacement spark plug.

Figure 4-38. Setting Spark Plug Gap

Results

1. Clean and re-gap or replace sparks plug as

necessary.

2. Refer back to the flow chart.

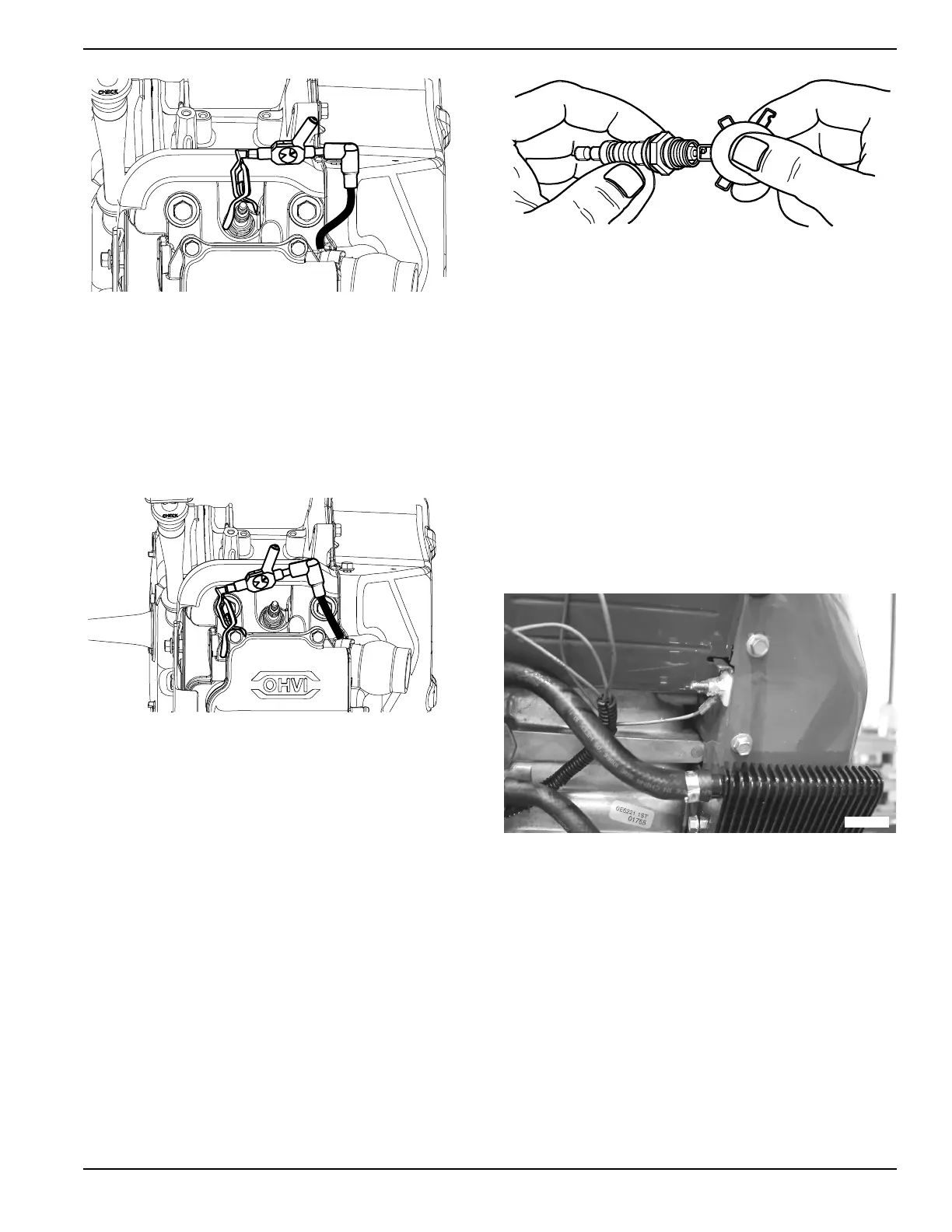

Test 31 – Remove Wire 18 / Shutdown

Lead

Procedure

1. See Figure 4-39. Disconnect wire 18 from the stud

located above the oil cooler.

2. Perform Test 29 again checking for spark.

Results

Refer back to flow chart.

Figure 4-39. Wire 18

Test 32 – Test Start Stop Relay (SSR)

Procedure

1. Set DMM to measure DC voltage.

2. See Figure 4-40. Remove wire 15 from Terminal

13 on the start stop relay (SSR).

3. Connect the positive meter test lead to wire 15

removed in step 2.

4. Connect the negative meter test lead to frame

ground.

a. If 12 VDC is measured proceed to step 5.

b. If 12 VDC is not measured repair or replace

wire 15 between the SSR and battery charge

rectifier 2 (BCR2).

Loading...

Loading...