Section 4 AC Diagnostic Tests

58 Diagnostic Repair Manual

Test 42 – Check Oil Pressure Switch

and Wire 86

• If the engine cranks and starts, then shuts down

almost immediately, the cause may be one or more

of the following:

• Low engine oil level

• Low oil pressure

• A defective oil pressure switch

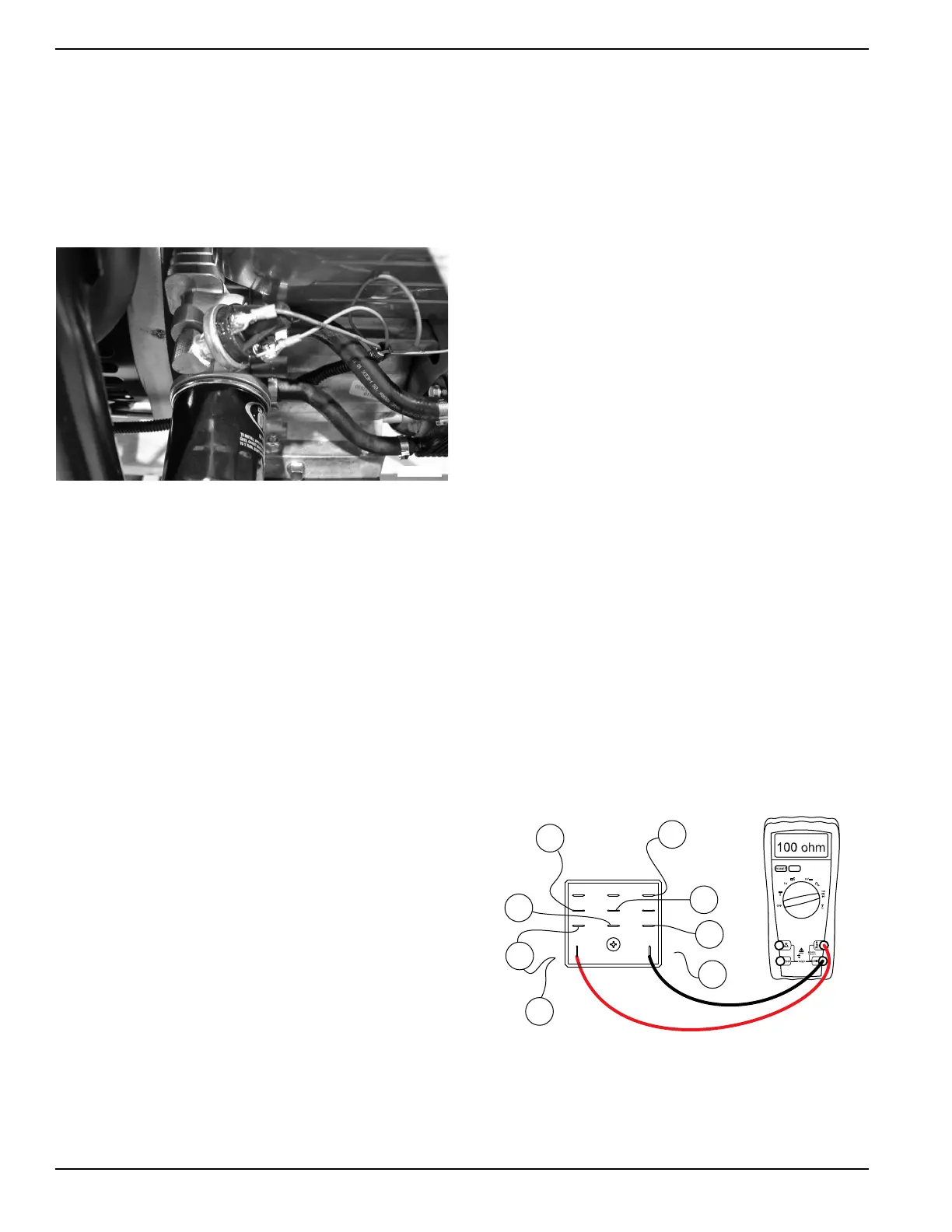

Figure 4-52. Low Oil Pressure Switch

Procedure

1. Check engine crankcase oil level. If necessary, add

the recommended oil to the dipstick FULL mark.

NOTE: Do not overfill above the full mark.

2. Disconnect wire 86 and wire 0 from the oil pressure

switch terminals.

3. Remove the switch and install an oil pressure

gauge in its place.

4. Start the engine while observing the oil pressure

reading on gauge. Normal oil pressure is

approximately 35-40 psi with engine running.

a. If normal oil pressure is indicated, go to step

11 of this test.

b. If oil pressure is below about 10 psi, shut

engine down immediately. A problem exists in

the engine lubrication system.

NOTE: The oil pressure switch is rated at 10 psi for v-

twin engines.

NOTE: Refer to Service Manual, Generac P/N 0F6923

for engine service recommendations.

5. Remove the oil pressure gauge and install the oil

pressure switch.

NOTE: Do not connect wire 86 or wire 0 to the switch

terminals.

6. Set DMM to measure resistance.

7. Connect the meter test leads across the switch

terminals.

a. With engine shut down, Continuity should be

measured.

8. Crank and start the engine.

a. Infinity should be measured.

9. Connect one test lead to wire 0 (disconnected from

LOP).

10. Connect the other test lead to a clean frame

ground.

a. Continuity should be measured.

b. If continuity is not measured repair or replace

wire 0 between the LOP and the ground

terminal connection on the engine mount.

11. If the LOP switch tests good in steps 5-10 and oil

pressure is good in steps 2-4, but the unit still shuts

down with a LOP fault, check wire 86 for a short to

ground.

12. Set DMM to measure resistance.

13. Disconnect the J2 connector from the circuit board.

14. Remove wire 86 from the LOP switch.

15. Connect one test lead to wire 86.

16. Connect the other test lead to a clean frame

ground.

a. Infinity should be measured.

b. If Continuity is measured, repair or replace

wire 86 between the LOP switch and the J2

connector.

Results

1. If switch tests good, refer to Flow Chart.

2. Replace switch if it fails the test.

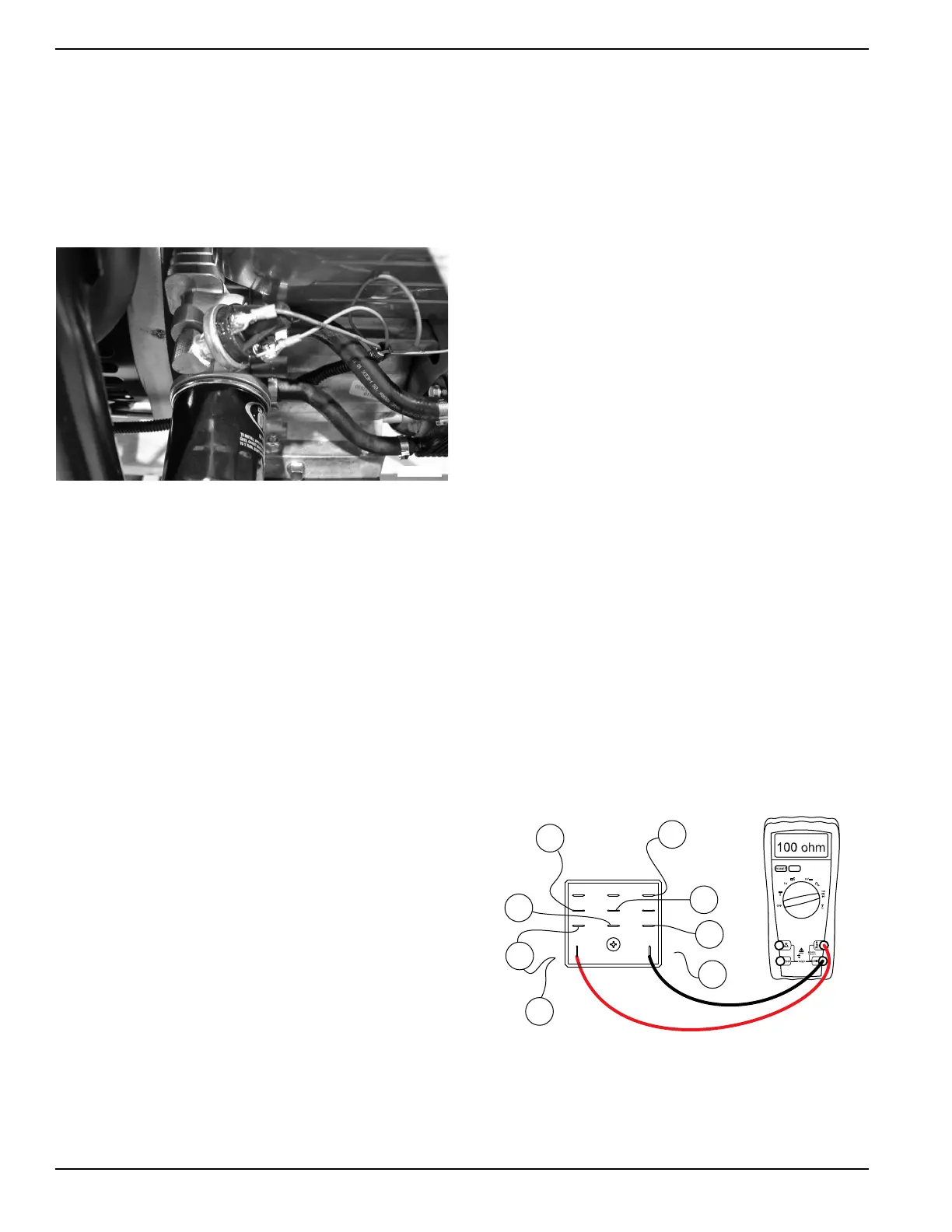

Test 43 - Check Start Stop Relay (SSR)

Procedure

1. Set DMM to measure resistance.

2. See Figure 4-53. Disconnect wire 15 and wire 229

from the Start Stop Relay (SSR).

Figure 4-53. Testing Start Stop Relay (SSR)

3. Connect one meter test lead to the terminal that

wire 15 was removed from.

4. Connect the other meter test lead to the terminal

that wire 229 was removed from.

SSR

15B

1413

9 10 12

5

1 2

6

4

8

229

0

18

14

15

15

15

Loading...

Loading...