Section 2 Direct Excitation (Brush Type)

Diagnostic Repair Manual 7

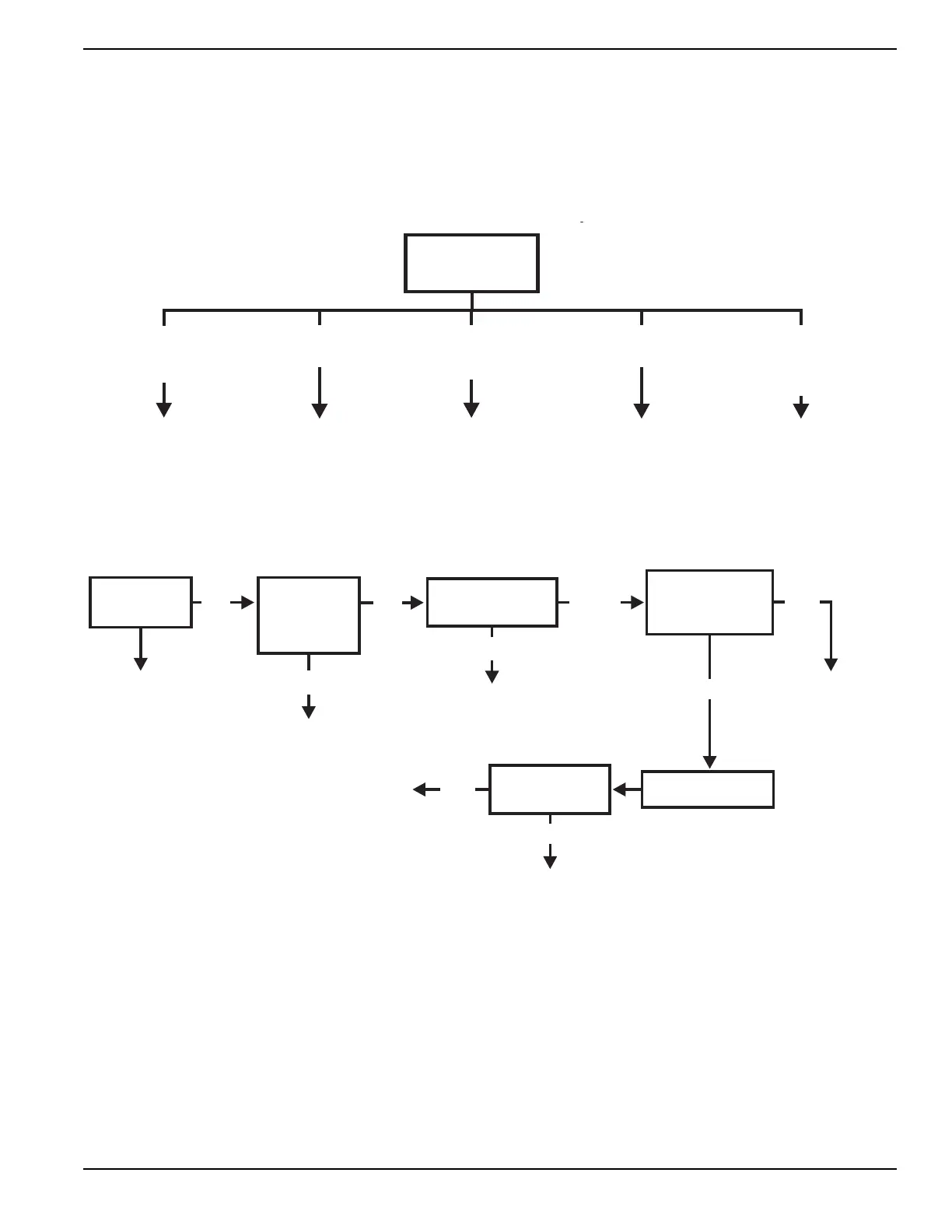

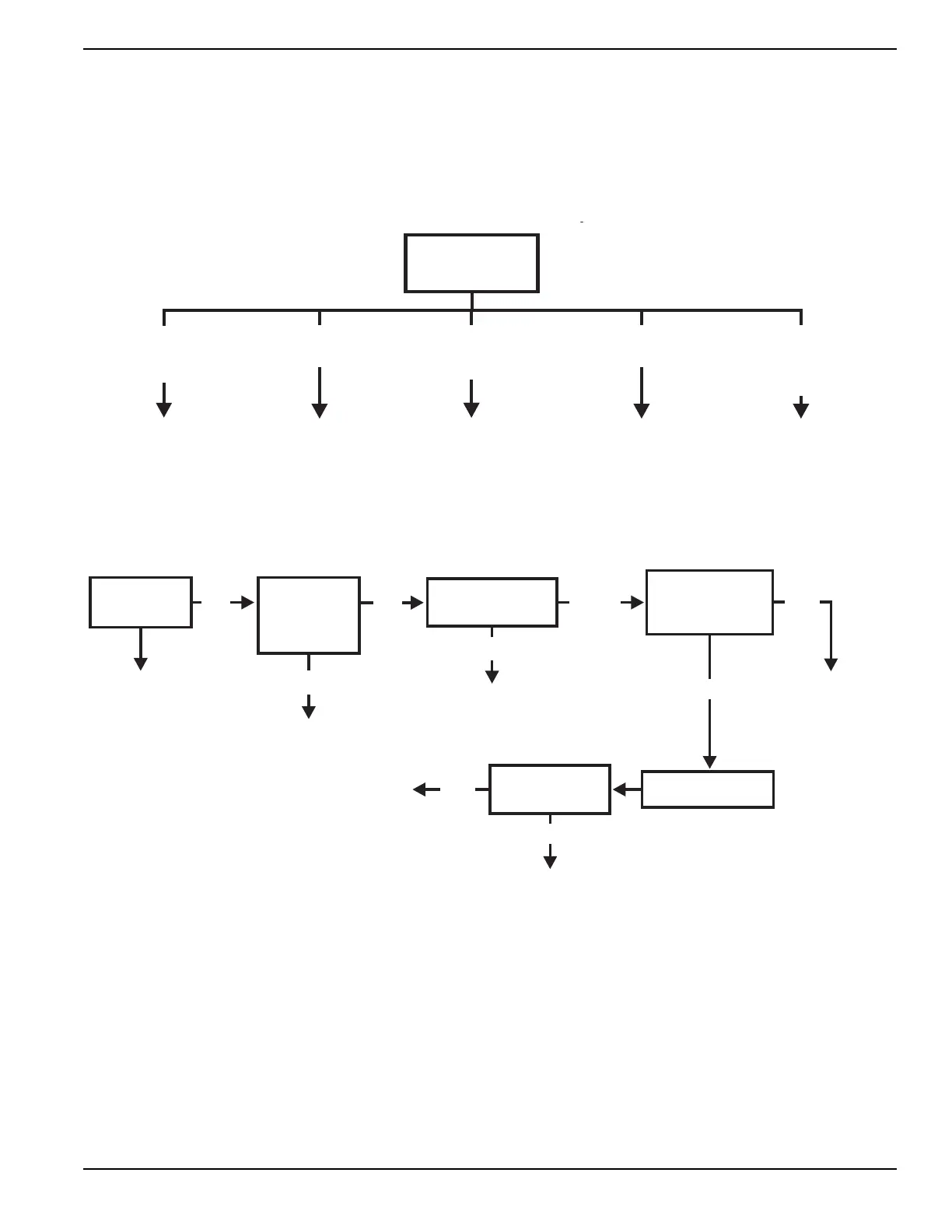

Troubleshooting Flowcharts

Introduction

Use the Flow Charts in conjunction with the AC Diagnostic Tests . Test numbers used in the flow charts correspond to

the numbered tests in the AC Diagnostic Tests . The first step in using the flow charts is to identify the correct problem

on the following pages. For best results, perform all tests in the exact sequence shown in the flow charts.

If Problem Involves AC Output (Brush Type)

Problem 5 – Generator Produces Zero Voltage or Residual Voltage

GO TO PROBLEM 6 GO TO PROBLEM 5GO TO PROBLEM 8 GO TO PROBLEM 7

VOLTAGE &

FREQUENCY BOTH

HIGH OR LOW

FREQUENCY GOOD

VOLTAGE HIGH

ZERO VOLTAGE

ZERO FREQUENCY

FREQUENCY GOOD,

LOW OR RESIDUAL

VOLTAGE

TEST 1 - CHECK

NO LOAD VOLTAGE

& FREQUENCY

NO LOAD VOLTAGE &

FREQUENCY GOOD -

VOLTAGE/FREQUENCY

FALLS OFF UNDER LOAD

p

VERIFY ROTOR IS SPINNING,

GO TO PROBLEM 5

BAD

BAD

GOOD

TEST 2 – CHECK

MAIN CIRCUIT

BREAKER

RESET TO “ON”

OR REPLACE IF BAD

REPLACE COMPONENT

AS NEEDED

REPLACE COMPONENT

AS NEEDED

TEST 3 – CHECK

CONTINUITY OF

RECEPTACLE PANEL

REPLACE

ALTERNATOR

REPLACE AUTOMATIC

VOLTAGE REGULATOR

TEST 4 – FIXED

EXCITATION

TEST/ROTOR AMP

DRAW TEST

ON

GOOD

STOP TESTING

GOOD

BAD

RE-CHECK VOLTAGE

AT RECEPTACLE

PANEL

TEST 13 –

TEST 120/240

CHANGEOVER

SWITCH

(IF EQUIPPED)

REPLACE SWITCH

ON

BAD

Loading...

Loading...