Diagnostic Repair Manual 17

Section 4 EFI Engine Control Diagnostic Tests

Basic EFI Theory

Electronic Fuel Injection was first introduced to

automobiles in the late 1960s. EFI is not new, as its roots

were firmly established many years ago. However, EFI is

fairly new to portable generators.

Basic Open-Loop Theory

EFI uses a solenoid valve called an injector to meter fuel

delivery. The typical system uses 1 injector per cylinder.

When the solenoid is energized, fuel sprays out into the

intake valve port. Fuel is delivered to the injector by a

high-pressure electric pump at approximately 36 psi. Fuel

delivery is controlled by the injector which is cycled by

the ECU. The ECU (Engine Control Unit) produces a

signal to open the injector for a certain length of time

depending on engine conditions transmitted by the

sensors. The longer the injector is open, the more fuel is

injected. As engine load increases, the injector open time

is increased to match the increased airflow. This ECU

output signal is called the injector pulse width. The longer

the pulse width, the more fuel is injected. In a typical

Open-Loop EFI system, there is no oxygen (O

2

) sensor

to monitor or change the fuel delivery.

Engine Requirements

The correct proportion of fuel is required to be mixed with

the incoming air for efficient operation. Most generator

engines utilize a ratio of approximately 14.7 parts air to 1

part fuel for the no load to full load power band. This is

the chemically correct ratio which results in the lowest

average emissions and best power. A rich condition is

characterized by an excess of fuel and a lean condition is

characterized by an excess of air or lack of fuel.

As the load is increased, up to capacity, the throttle is

opened and as airflow increases fuel flow must increase

to match it.

Fuel System

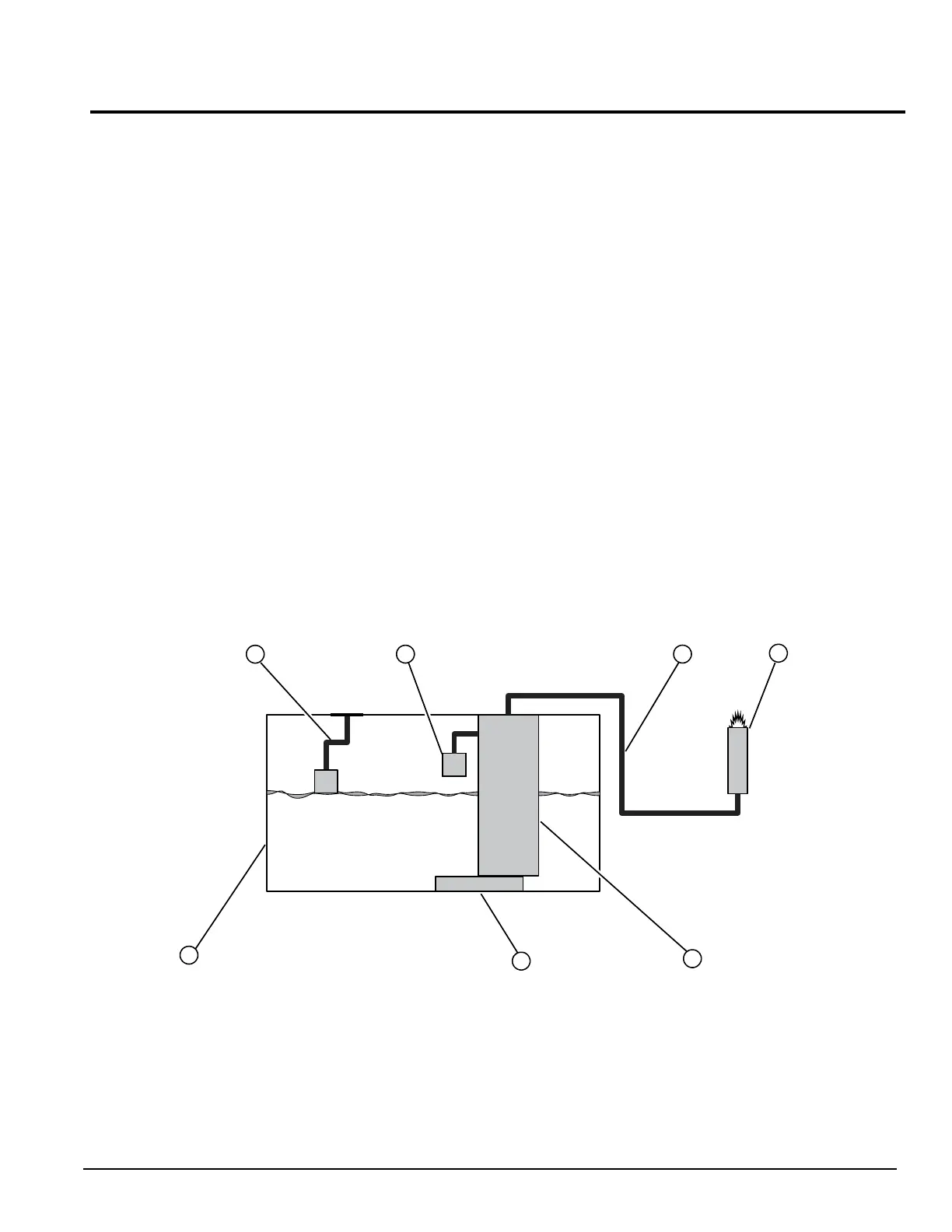

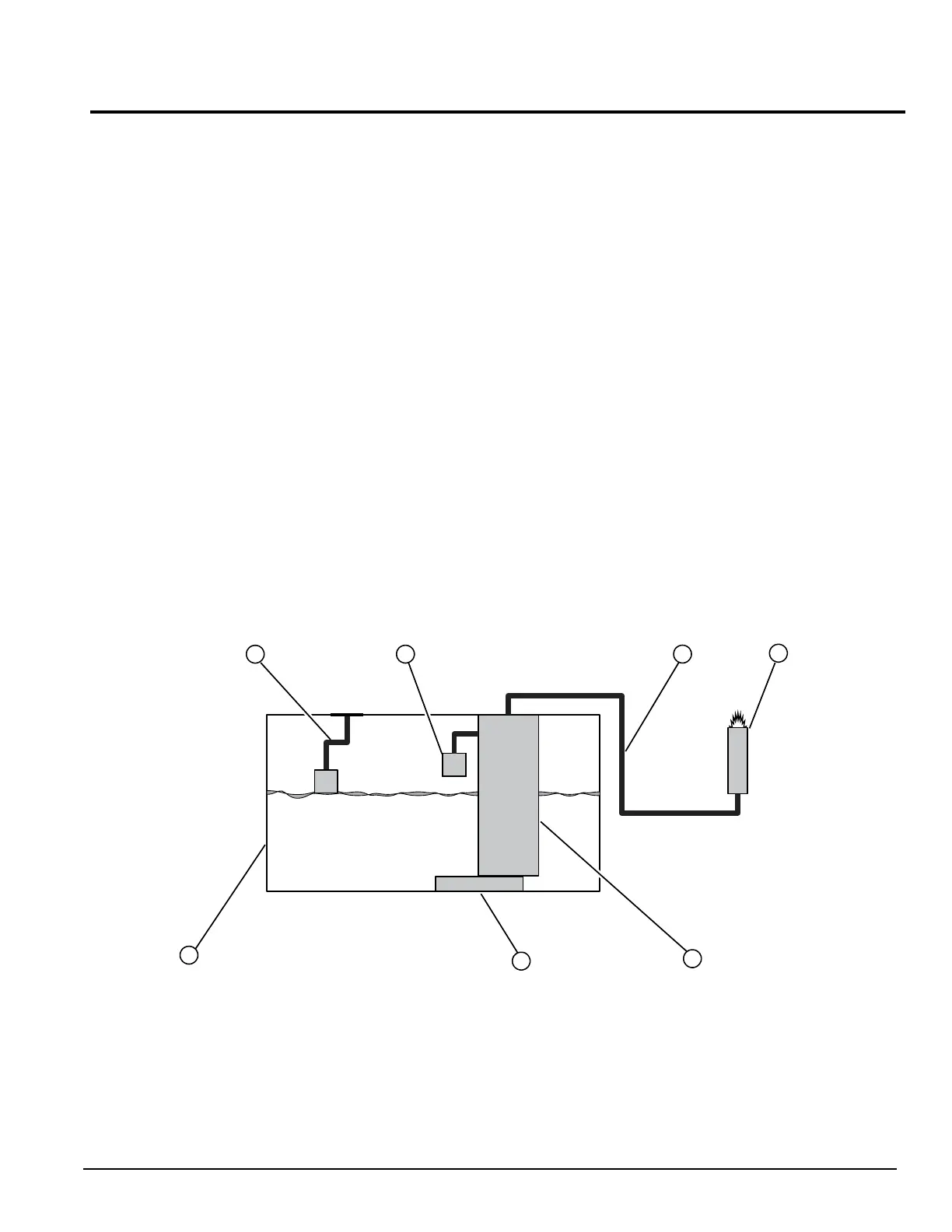

See Figure 4-1. EFI fuel systems consist of a tank,

pump, regulator, and injector. Fuel is drawn from the tank

by the pump which steps up the pressure to

approximately 36 psi. Fuel pressure is controlled by the

fuel pressure regulator located in the fuel pump,

discharging unused fuel back into the tank. When load

demand increases, there is sufficient fuel available. The

injector is sealed with an O-ring and has a 2-pin electrical

plug to carry switching current to the solenoid windings.

When energized, the solenoid core is pulled back,

allowing fuel to spray out in a fine, conical pattern.

Figure 4-1. Return-less System

A. Fu

el Gauge / Float C

. Pre

ssure Line

E. Fu

el Pump

G.

Fuel Tank

B.

Pre

ssure Regulator D.

F

uel Injector F.

F

uel Filter

Loading...

Loading...