Section 5 Engine Diagnostic Tests

Diagnostic Repair Manual 29

4. Broken, damaged or weak magnets.

5. Starter drive dirty or binding.

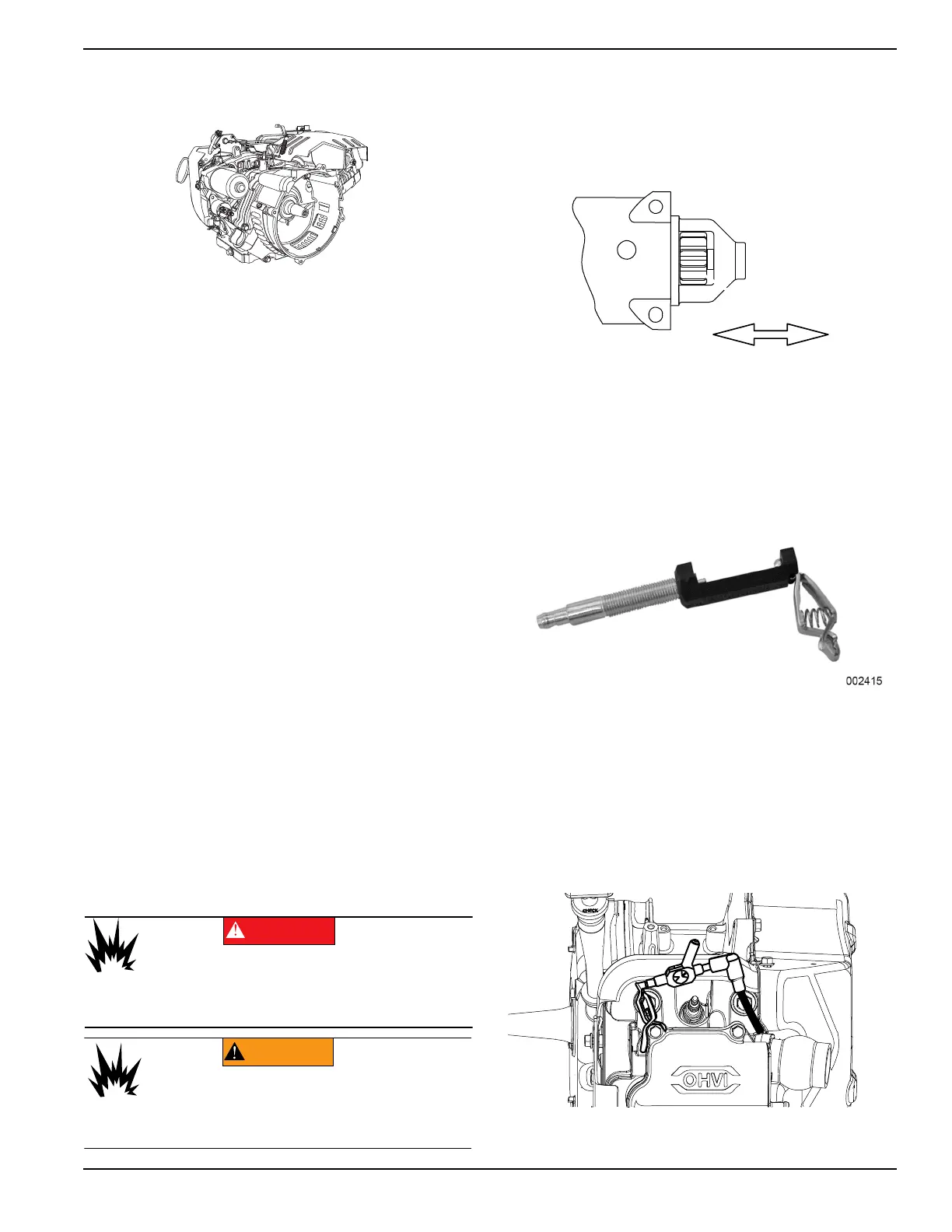

Figure 5-6. Starter Motor (SM)

Procedure

The battery should have been previously checked and

fully charged.

Set a DMM to measure DC voltage (12 VDC). Connect

meter positive (+) test lead to starter contactor stud (the

small jumper wire connected to starter). Connect

common (-) test lead to starter motor frame.

Set Start-Stop Switch to START and observe meter.

Meter should indicate battery voltage. Starter motor

should operate and engine should crank.

Results

1. If battery voltage is indicated on meter but motor

did NOT operate, remove and test starter motor for

proper operation independent of engine.

2. If battery voltage was indicated and Starter Motor

tried to engage (pinion engaged) but engine did not

crank, check for mechanical binding of engine or

rotor.

NOTE: If a starting problem is encountered, the engine

itself should be thoroughly checked to eliminate it as the

cause of starting difficulty. It is good practice to check

engine for freedom of rotation by removing spark plugs

and turning crankshaft over slowly by hand to be sure it

rotates freely.

IMPORTANT NOTE: Do not rotate engine with electric

starter with spark plugs removed. Arcing at the spark

plug ends may ignite the gasoline vapor exiting the spark

plug hole.

Checking The Pinion

See Figure 5-7. When starter motor is activated, the

pinion gear should move and engage flywheel ring gear.

If pinion does not move normally, inspect pinion for

binding or sticking.

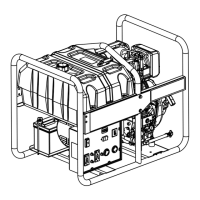

Figure 5-7. Check Pinion Gear Operation

Test 20 – Check Ignition Spark

Procedure

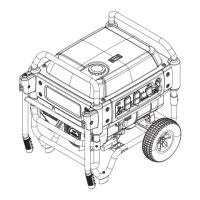

A commercially available spark tester may be used to

test engine ignition system. One can also be purchased

from Generac or local supplier.

Figure 5-8. Spark Tester

1. Disconnect spark plug lead from spark plug.

2. Attach high tension lead to spark tester terminal.

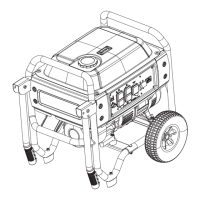

3. See Figure 5-9 and Figure 5-10. Ground spark

tester clamp by attaching to cylinder head.

4. Crank engine rapidly. Engine must crank at 350

rpm or more. If spark jumps tester gap, assume the

ignition system is working properly. Repeat on

remaining cylinder spark plug.

Figure 5-9. Testing Ignition System

(000143)

DANGER

Explosion and Fire. Fuel and vapors are extremely

flammable and explosive. Store fuel in a well

ventilated area. Keep fire and spark away. Failure

to do so will result in death or serious injury.

WARNING

Explosion. Turn fuel supply OFF before

checking for spark. Failure to do so could

result in death or severe injury.

(000333)

Loading...

Loading...