Section 5 Engine Diagnostic Tests

32 Diagnostic Repair Manual

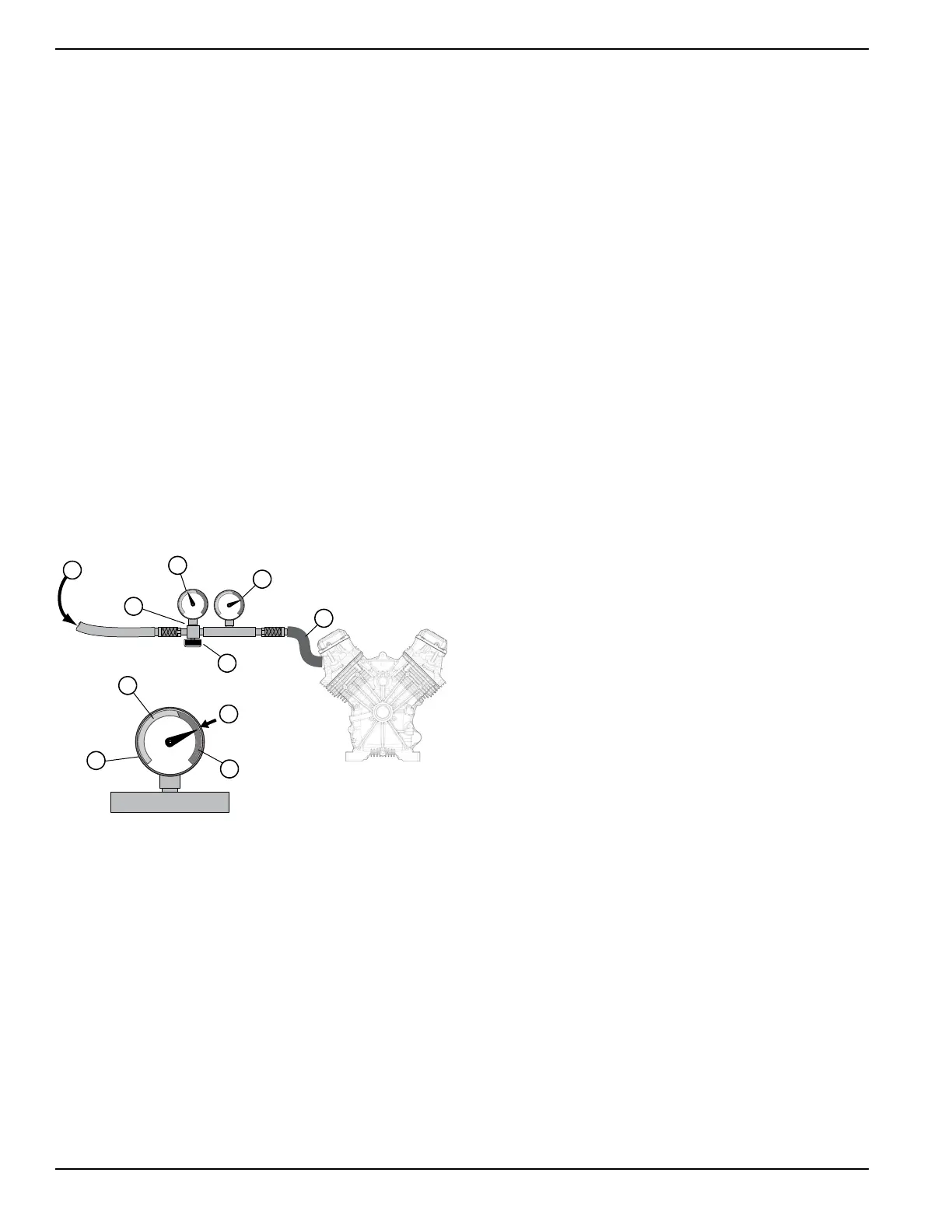

Test 25 – Check Engine / Cylinder

Leak Down Test / Compression Test

General Theory

Most engine problems may be classified as one, or a

combination of the following:

• Will not start

• Starts hard

• Lack power

• Runs rough

• Vibration

• Overheating

• High oil consumption

General Theory

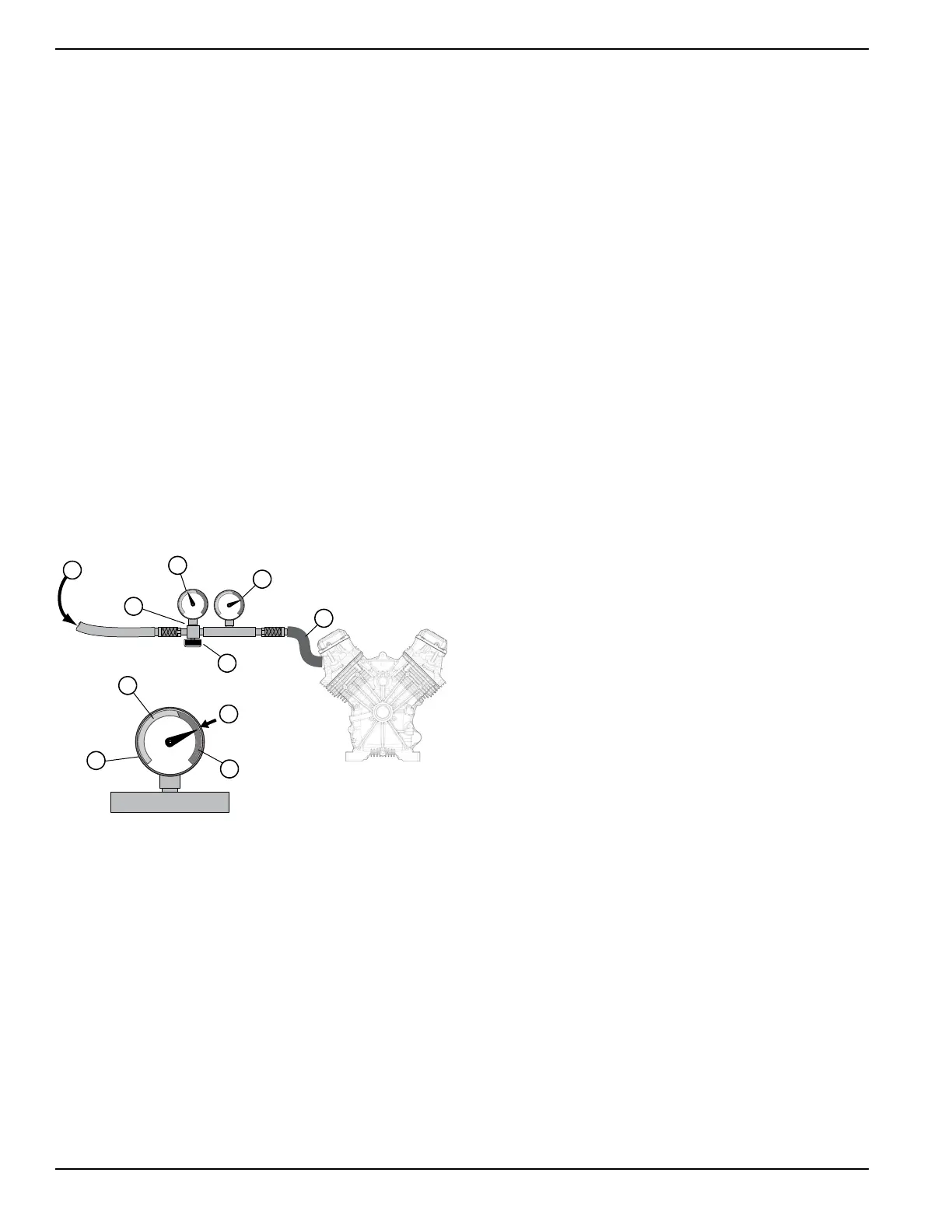

The Cylinder Leak Down Tester checks sealing

(compression) ability of engine by measuring air leakage

from combustion chamber. Compression loss can

present many different symptoms. This test detects the

section of the engine where the fault lies before

disassembling the engine. Figure 5-16 represents a

standard tester available on the market.

Figure 5-16. Cylinder Leakdown Tester

Procedure

1. Shut off the fuel supply.

2. Remove spark plug.

3. Gain access to flywheel.

4. Remove valve cover.

5. Rotate engine crankshaft until the piston reaches

top dead center (TDC). Both valves should be

closed.

6. Lock flywheel at top dead center.

7. Attach cylinder leak down tester adapter to spark

plug hole.

8. Connect an air source of at least 90 psi to the leak

down tester.

9. Adjust regulated pressure on gauge to 80 psi.

10. Read right hand gauge on tester for cylinder

pressure. 20 percent leakage is normally

acceptable. Use good judgment, and listen for air

escaping at carburetor, exhaust, and crankcase

breather. This determines where the fault lies.

Results

•

Air escapes at carburetor – check intake valve.

• Air escapes through exhaust – check exhaust

valve.

• Air escapes through breather – check piston rings.

• Air escapes from cylinder head – replace head

gasket.

Check Compression

To check engine compression, remove spark plug. Insert

an automotive type compression gauge into the spark

plug hole. Crank engine until there is no further in

pressure. The highest reading obtained is engine

compression pressure.

Minimum Allowable Compression Pressure Cold

Engine – 60 psi

If compression is poor, look the following causes:

• Loose cylinder head bolts

• Failed cylinder head gasket

• Burned valves or valve seats

• Insufficient valve clearance

• Warped cylinder head

• Warped valve stem

• Worn or broken piston ring(s)

• Worn or damaged cylinder bore

• Broken connecting rod

• Worn valve seats or valves

• Worn valve guides

NOTE: Refer to Engine Service Manual Part Number

0C1103A for further engine service information on the

410cc engine.

NOTE: Refer to Engine Service Manual Part Number

10000016870 for further engine service information on

the 426cc engine.

A. Compressed air in

B. Air pressure regulator

C. Inlet gauge pressure set point

D. Outlet gauge pressure

E. To spark plug hole

F. Regulator adjustment knob

G. Outlet gaug

e

H.

Red range indicates unacceptable leakage

I. Needle indicates minimal air leakage

J. Green range indicates acceptable leakage

A

C

B

D

E

F

I

J

G

H

Loading...

Loading...