Section 5 Engine Diagnostic Tests

28 Diagnostic Repair Manual

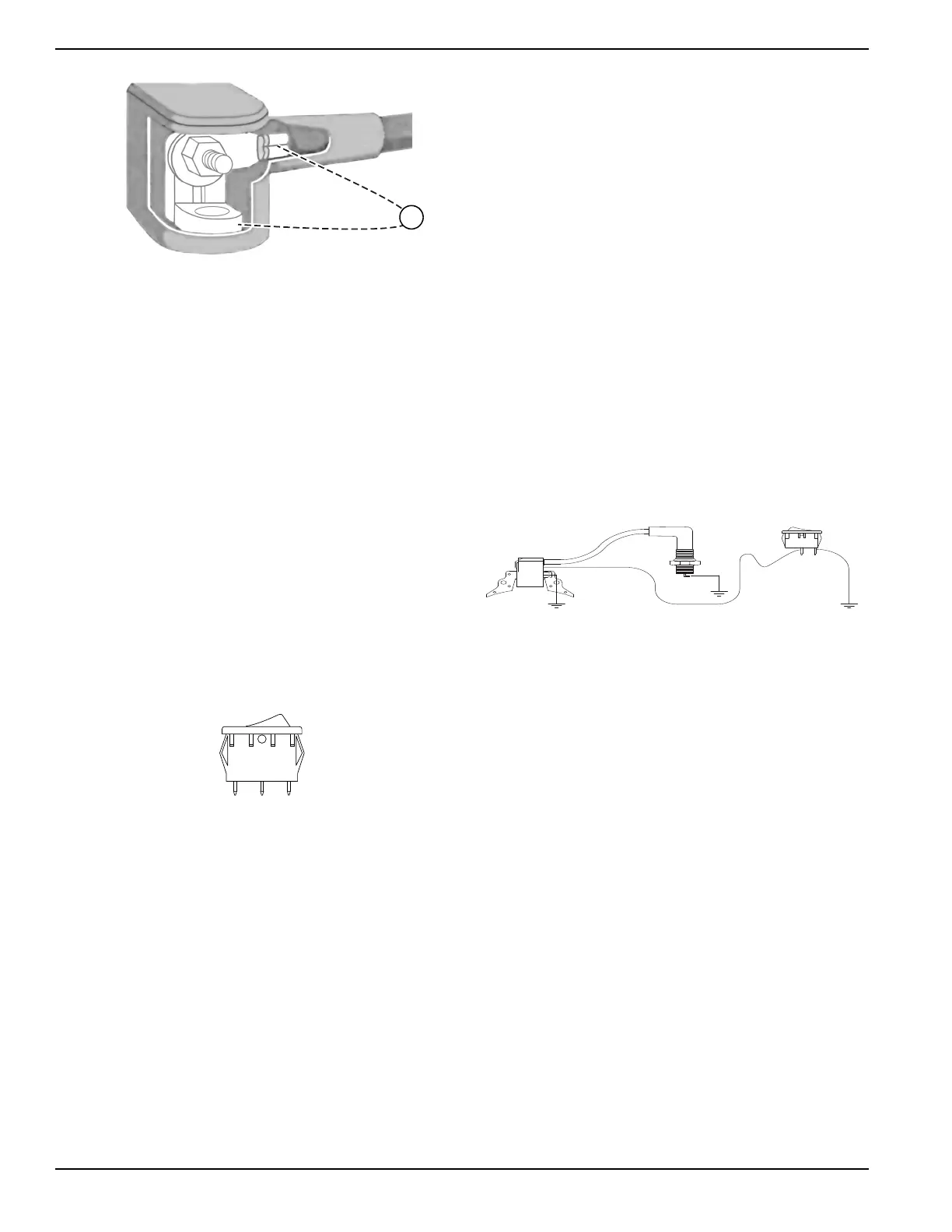

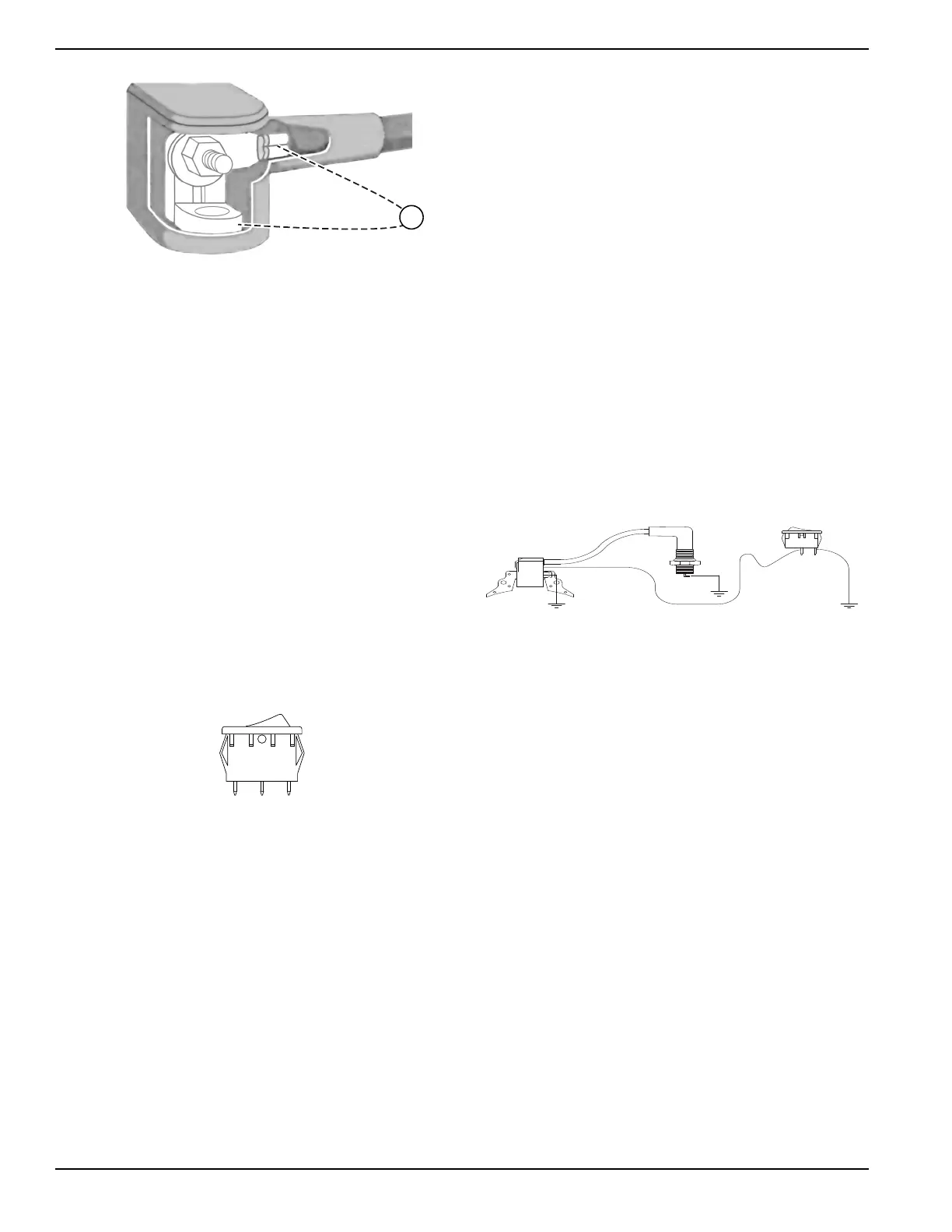

Figure 5-3. Starter Circuit Voltage Drop Test

Connections

7. If voltage drop is greater than the above, based on

the circuit or component, clean or replace the failed

connection or component. If voltage drop test

results are within the above, based on the circuit or

component, refer back to the flowchart.

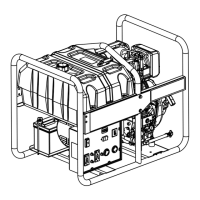

Test 17 – Check START-RUN-STOP

Switch (410/426cc Engine)

General Theory

See Figure 5-4. The START-RUN-STOP switch utilizes

ground potential to start and shutdown the engine. When

the switch is actuated to START, positive 12 VDC is

delivered to the starter contactor, allowing the engine to

crank. Once positive 12 VDC is removed, by releasing

the switch to the RUN position, it disengages the starter

allowing the engine to operate. When switch is actuated

to STOP, ground is applied to the magneto coil(s) which

inhibits spark from occurring.

Figure 5-4. START-RUN-STOP Switch

Procedure

1. Set a digital multimeter (DMM) to measure

resistance.

2. Remove all wires from START-RUN-STOP Switch

(SW1).

3.

Connect one meter lead to Terminal 2 and the other

meter lead to Terminal 1. Actuate switch to START

position. CONTINUITY should be measured.

4. Actuate switch to the STOP position. INFINITY

should be measured.

5. Keep one meter lead on Terminal 2 and connect

the other meter lead to Terminal 3. Actuate switch

to the STOP position. CONTINUITY should be

measured.

6. Actuate switch to START position. INFINITY

should be measured.

7. Connect one meter test lead to disconnected Wire

0 from Terminal 2 and connect the other meter test

lead to the positive post of the battery, 12 VDC

should be measured. If voltage is not measured,

repair or replace Wire 13A between the starter

contactor and the START-RUN-STOP switch.

8. Connect all wires to the switch.

Results

1. If any other readings were measured, replace

START-RUN-STOP switch.

2. Refer to flow chart.

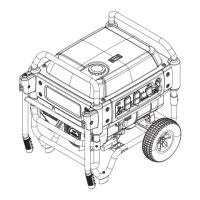

Test 18 – Test OFF-ON Switch

General Theory

The OFF-ON switch applies a ground to the shutdown

harness (Wire 18). Applying ground to the harness

grounds out the magneto and inhibits spark.

Procedure

1. See Figure 5-5. Disconnect Point A from switch.

Figure 5-5. OFF-ON Switch Test Points

2. Connect one meter lead to male connector on

switch and the other meter test lead to a clean

frame ground.

3. Actuate switch back and forth between ON and

OFF. CONTINUITY should only be measure in the

OFF position.

Results

1. If switch failed Step 3, replace OFF-ON switch.

2. If OFF-ON switch is good, refer to flow chart.

Test 19 – Check Starter Motor

The following conditions affect starter motor

performance:

1. Binding or seizing in starter motor bearings.

2. A shorted, open, or grounded armature.

a. Shorted, armature (wire insulation worn an

d

wire

s touching),. indicated by low or no RPM.

b. Open armature (wire broken), indicated by lo

w

or

no RPM and excessive current draw.

c. Grounded armature (wire insulation worn and

wire touc

hing armature lamination or shaf

t),

in

dicated by excessive current draw or no RPM.

3. A defective starter motor switch.

Loading...

Loading...