Diagnostic Repair Manual 9

Section 3 AC Diagnostic Tests

Introduction

Perform the Diagnostic Tests in this section in

conjunction with the Brushless Troubleshooting

Flowcharts or the Brush Type Troubleshooting

Flowcharts. Test numbers in this section correspond to

numbered tests in the flow charts.

NOTE: Test procedures in this manual are not

necessarily the only methods for diagnosing the condition

of components and circuits. All possible methods that

might be used for system diagnosis have not been

evaluated. If any diagnostic method is used other than

the method presented in this manual, the technician must

be sure that neither personal safety nor product safety,

will be endangered by the procedure or method selected.

NOTE: For graphics of different configurations of stators

and the wire numbers associated with different

components, see appropriate wiring diagrams and

schematics for the generator.

Test 1 – Check No-Load Voltage and

Frequency

Procedure

1. Disconnect or turn OFF all electrical loads

connected to the generator.

2.

Set digital multimeter (DMM) to measure AC voltage.

3. Reset all circuit breakers to ON.

4. Start engine and let stabilize and warm up.

5.

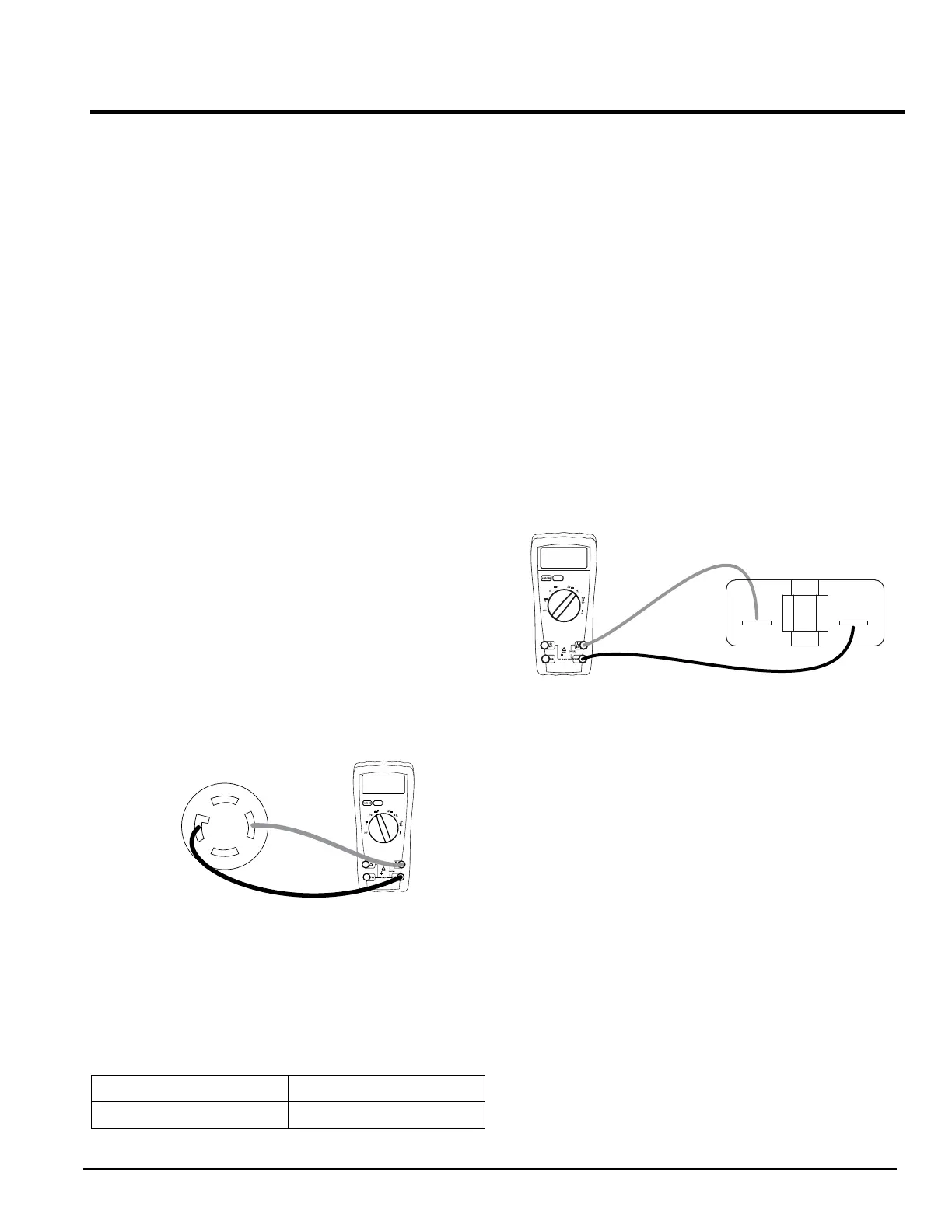

See

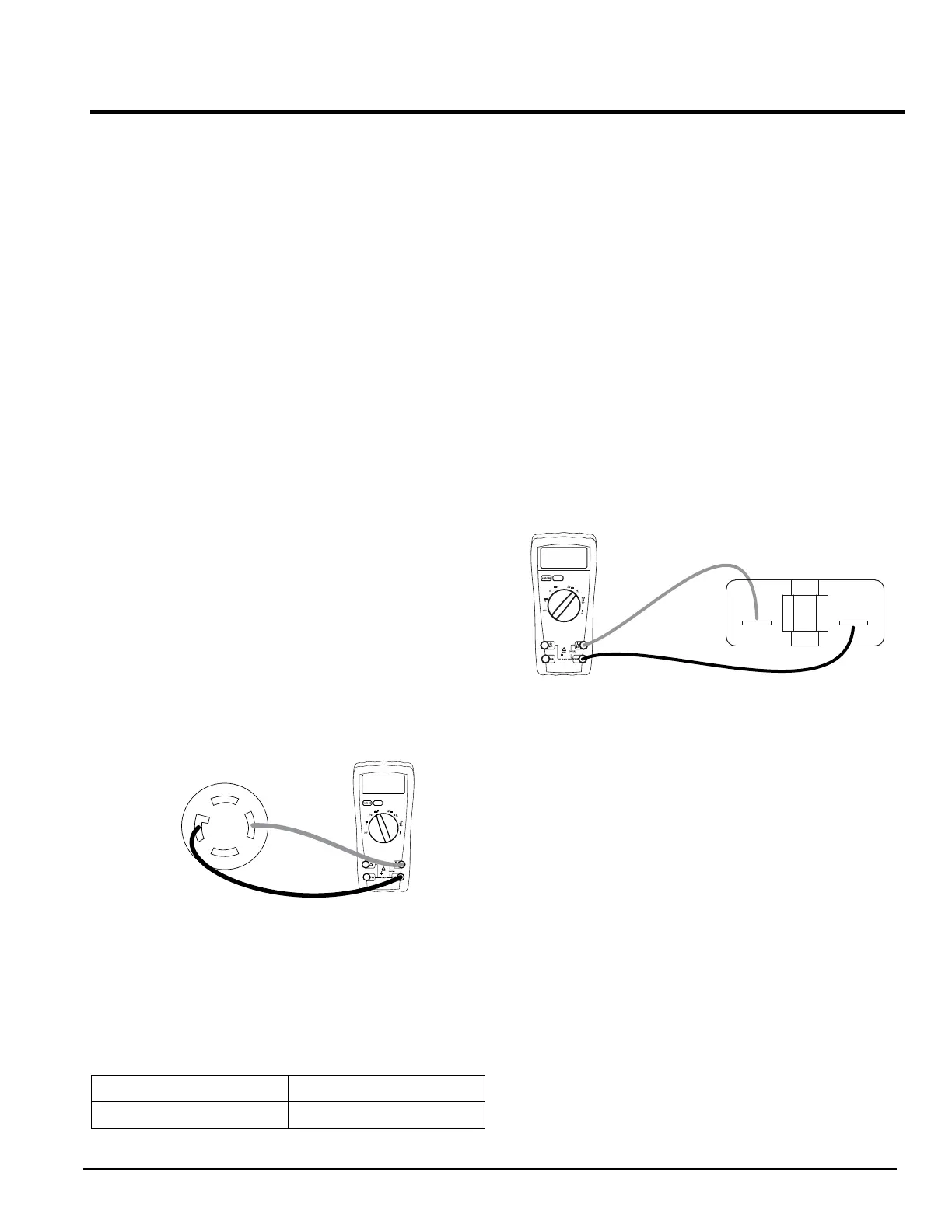

Figure 3-1

. Place meter test leads into an

outlet.

Figure 3-1. DMM Test Leads Connected to a 240 VAC

Receptacle

6. Read AC voltage.

7. Connect an AC frequency meter as described in

Step 5.

8. Read AC frequency.

Results

Refer to flow chart.

Test 2 – Check Main Circuit Breaker

Procedure

The generator has circuit breakers located on the control

panel. If outlets are not receiving power, make sure

breakers are set to ON or “Closed”.

If a breaker is suspected to have failed, test as follows:

1. Set DMM to measure resistance.

2. With generator shut down, disconnect all wires

from suspected circuit breaker terminals to prevent

interaction.

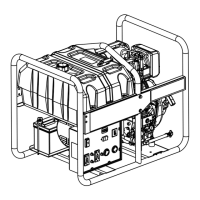

3. See Figure 3-2. With the generator shut down,

connect one meter test lead to one terminal of the

breaker and the other meter test lead to the other

termi

nal.

4. Set breaker to ON or “Closed”. The meter should

read CONTINUITY.

5. Set breaker to OFF or “Open”. The meter should

indicate INFINITY.

Figure 3-2. 20/30 Amp Breaker Test Points

Results

1. If circuit breaker tests good, refer to flow chart.

2. If breaker tests bad, replace.

Test 3 – Check Continuity of

Receptacle Panel

General Theory

Continuity of the receptacle panel is important as it

recognizes the receptacle has continuity through the

wiring and is physically connected to the stator. Most

stator winding values are between 0.01 and 0.02 Ohms

of resistance. If a higher than normal value is shown, a

poor connection could be the problem preventing that

receptacle from receiving power.

Procedure

1. Set DMM to measure Resistance.

2. See Figure 3-3. Connect DMM to each receptacle

on unit.

NOTE: Only one outlet on each receptacle needs to be

tested.

No Load Voltage No Load Frequency

223.2 – 256.8 VAC 62.5 – 62.0 Hz

Loading...

Loading...