- 64 -

6.3 Ignition system inspection

*Note

•When there is no spark in the spark plug, inspect

whether the wire or part is loosen or in poor contact and

confirm whether each voltage value is normal.

•Since there are a great many of avometer brands with

different interior resistance, the values tested will differ

accordingly.

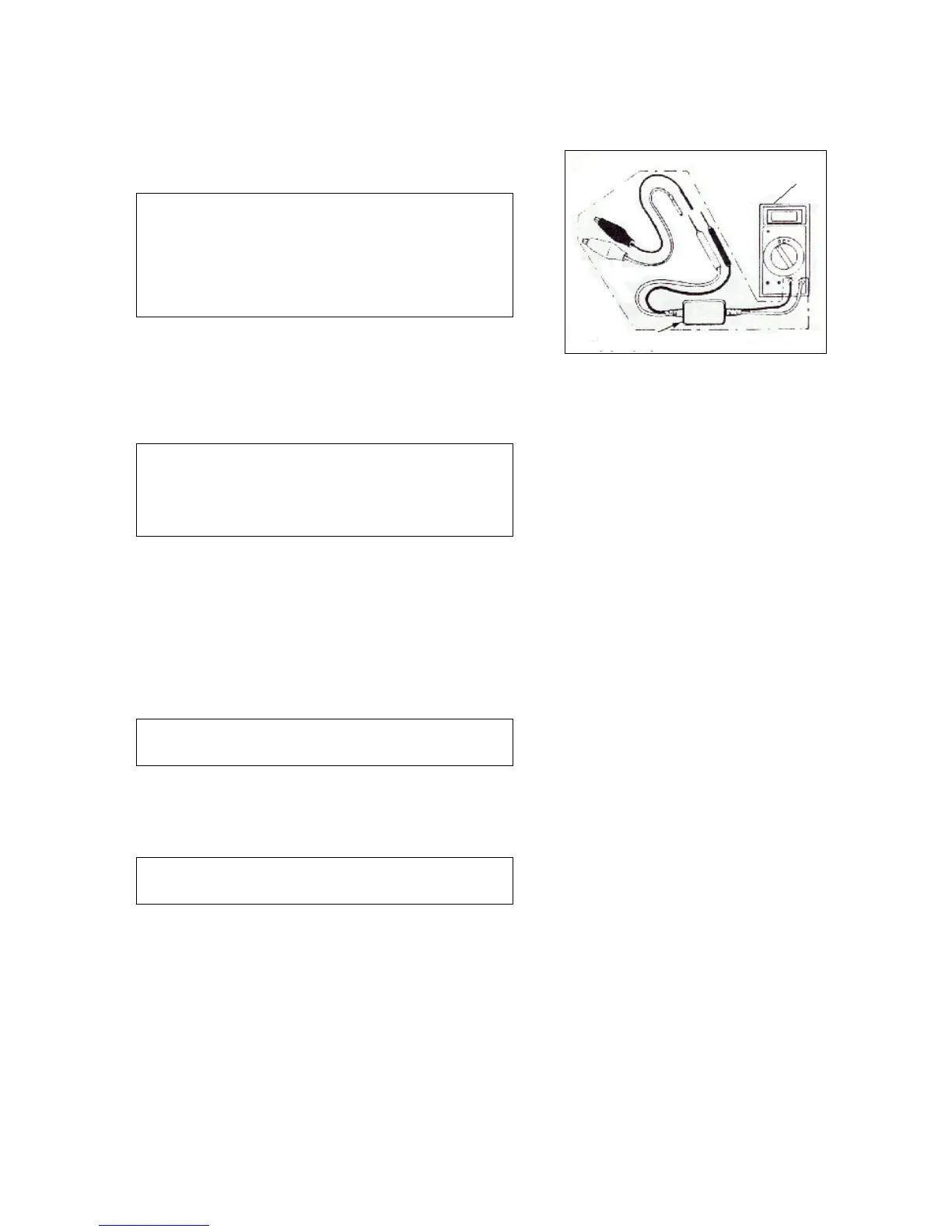

Connect the avometer with a high voltage diverter or an

electric meter with input resistance above 10MΩ10CV.

6.3.1 Primary voltage of ignition coil

Replace the spark plug with a good one and connect it with the engine. *Note

Correctly connect each circuit before the test.

Normal compression pressure of the air cylinder is

achieved in the test when the spark plug is installed on the

cylinder head.

Remove the middle cover.

Connect the wire of ignition coil and connect the primary

coil terminal(black / white) with the diverter at the

Ground. Press the startup electrical machinery or step on

the actuating lever to measure the primary peak voltage of

the ignition coil. Minimum voltage:95V or above.

*Note

The metal area of the avometer prod mustn't be touched

by fingers to prevent electroshock.

6.3.2 Charge coil

*Note

Install the spark plug on the air cylinder head and inspect

with normal compression pressure.

Remove the 4P and 2P joint of CDI group, and connect a

High Voltage diverter between the charge coil of the 2P

joint (red / white terminal)to the wire and the 4P joint

(black terminal). Press the startup motor or step on the

actuating lever to measure the peak voltage of the charge

coil.

Connecting method: positive pole connected with red /

white line, and negative pole connected with black line.

avometer

hi

Loading...

Loading...