- 85 -

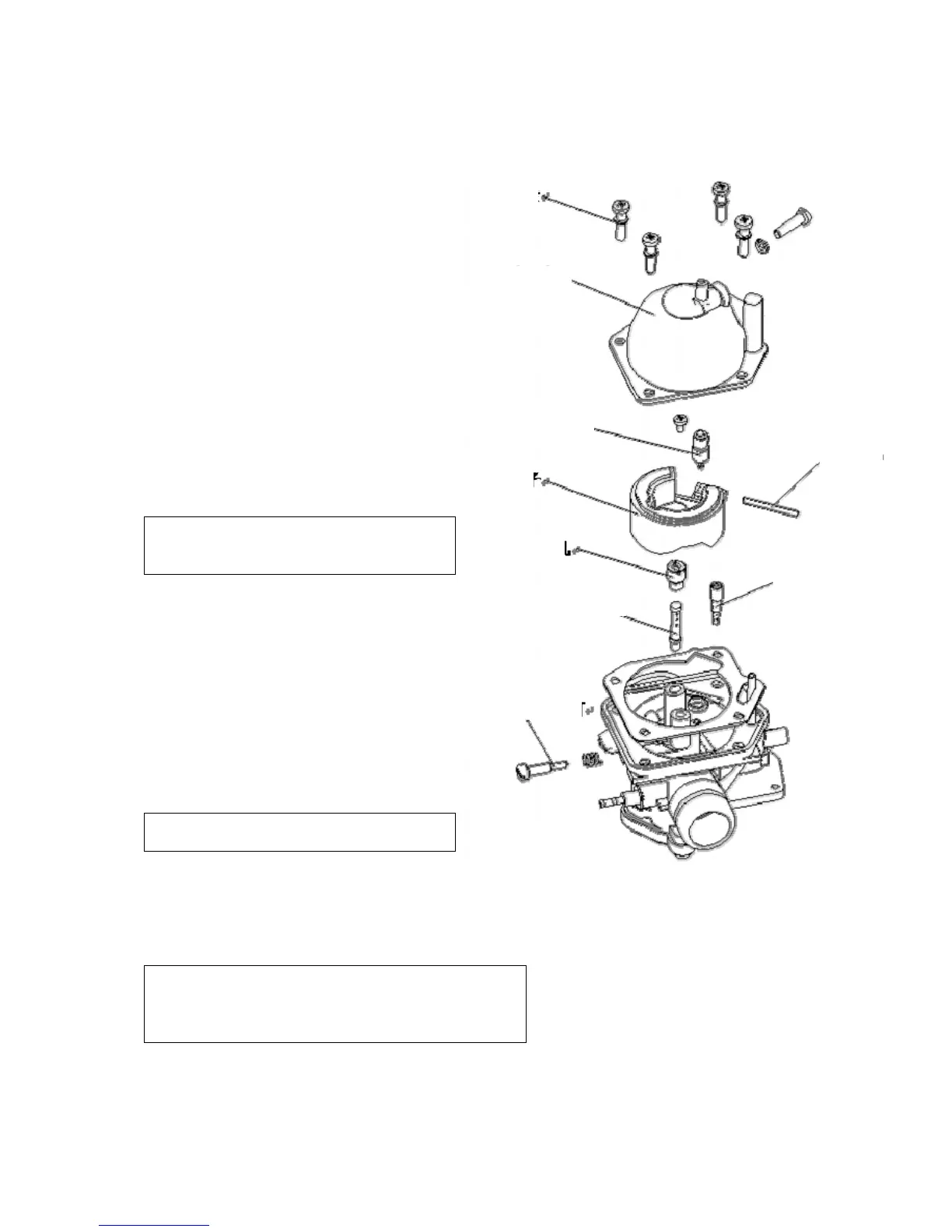

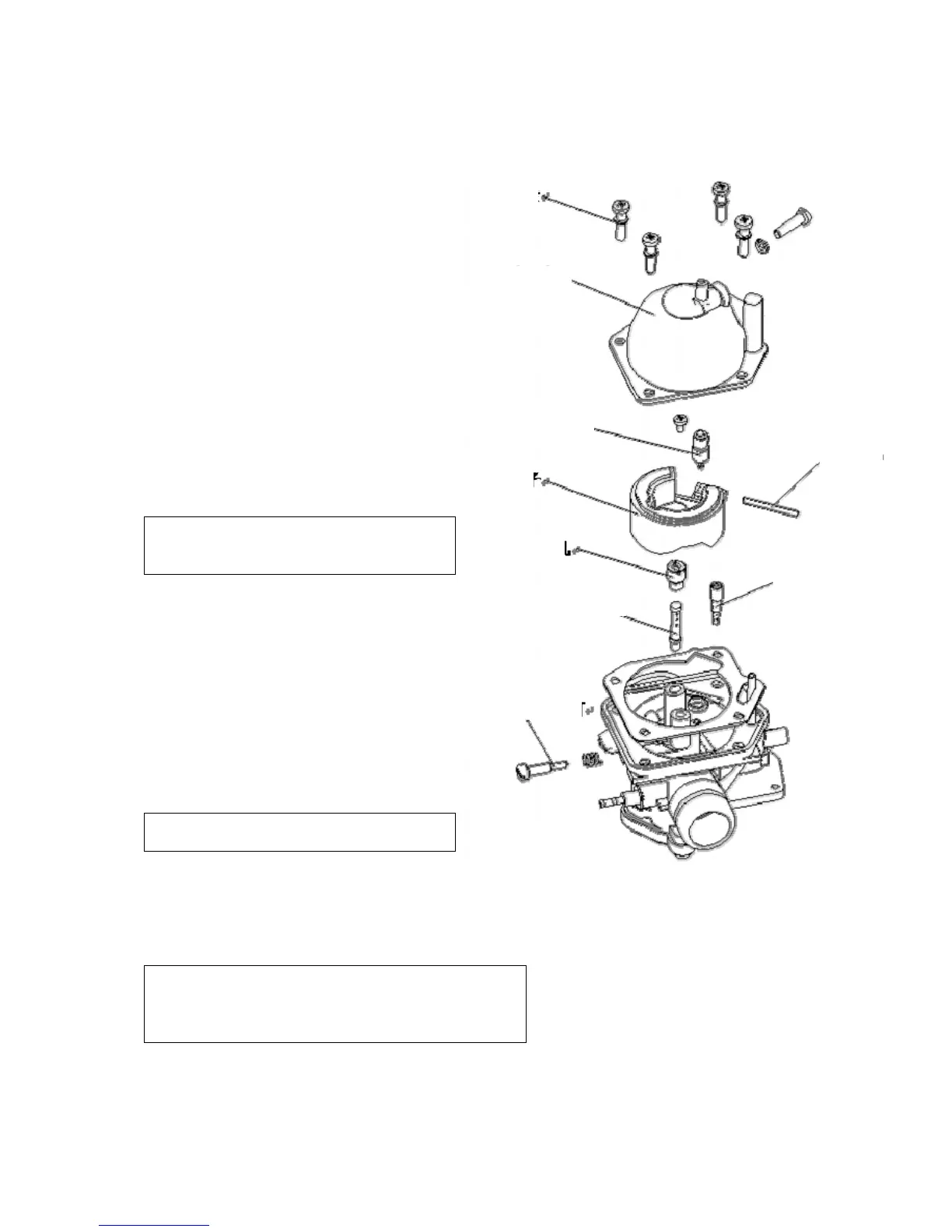

10.5 Float chamber

10.5.1 Dismantling

Dismantle the four fixing bolts and unload the

float chamber.

Dismantle the float pin and unload the float and

needle valve set.

Dismantle the main jet, main bubble tube and

idle jet.

Dismantle the idle adjustment bolts.

10.5.2 Inspection

Inspect whether the needle valve set is worn out

or damaged. If it's true, replace it with a new

product and replace the main jet at the same

time.

Inspect whether the idle jet, main jet and main

bubble tube is worn out, damaged or polluted.

If it's true, replace them.

Note:

Clean every part of the carburetor with gasoline

and blow them dry with high pressure air.

10.5.3 Assembly

Assembly is conducted in the reverse order of

disassembly.

10.6 Installation of carburetor

Assembly is conducted in the reverse order of

disassembly.

Note:

Assembly is conducted in the reverse order of disassembly.

Install the carburetor in the reverse order of disassembly.

10.6.1Adjustment of carburetor

Note:

The idle adjustment bolt was adjusted when delivered out

of the factory and needs no readjustment. When

dismantling, take down the turning circle number for the

benefit of installation.

Switch on and warm up the machine for about 3 minutes, so that the engine will operate in normal running

temperature.

Adjust the idle adjustment bolts and set engine speed to be 1400rpm.

Screw the mixture adjustment bolt to the end with proper force.

The idle adjustment bolt and nozzle shouldn't

be damaged. When screwing off the idle

adjustment bolts,memorize the circle number.

The idle speed must be adjusted after the

installation.

bolt

float chamber

needle valve set

float

main jet

float pin

main bubble tube

idle adjustment bolt

idle jet

Loading...

Loading...