- 96 -

12 Crankcase/clutch/actuating lever

Preparation data ----------------12.1

Fault diagnosis -----------------12.2

Crankcase -----------------------12.3

Clutch ---------------------------12.4

Actuating lever -----------------12.5

12.1 Preparation data

Matters needing attention in operation

Since the crankcase is a thin-section casting, please avoid impact on it during operation in case there is any

distortion or rupture.

All parts should be cleaned before inspection and test and should be blow dry with high pressure air.

Before operation, discharge the lubricating oil in the crankcase.

Function of the crankcase:the bearing part of the engine. Its primary function is supporting the

crankshaft, clutch, gearbox, cylinder body as well as the cylinder cover and bearing bursting impact of

combustion and movement inertia force of crankshaft connecting rod system and constituting some closed

(oil, air seal) space. The crankcase has a hanging hole which links the engine and the frame with other parts

by connecting with the hanging hole.

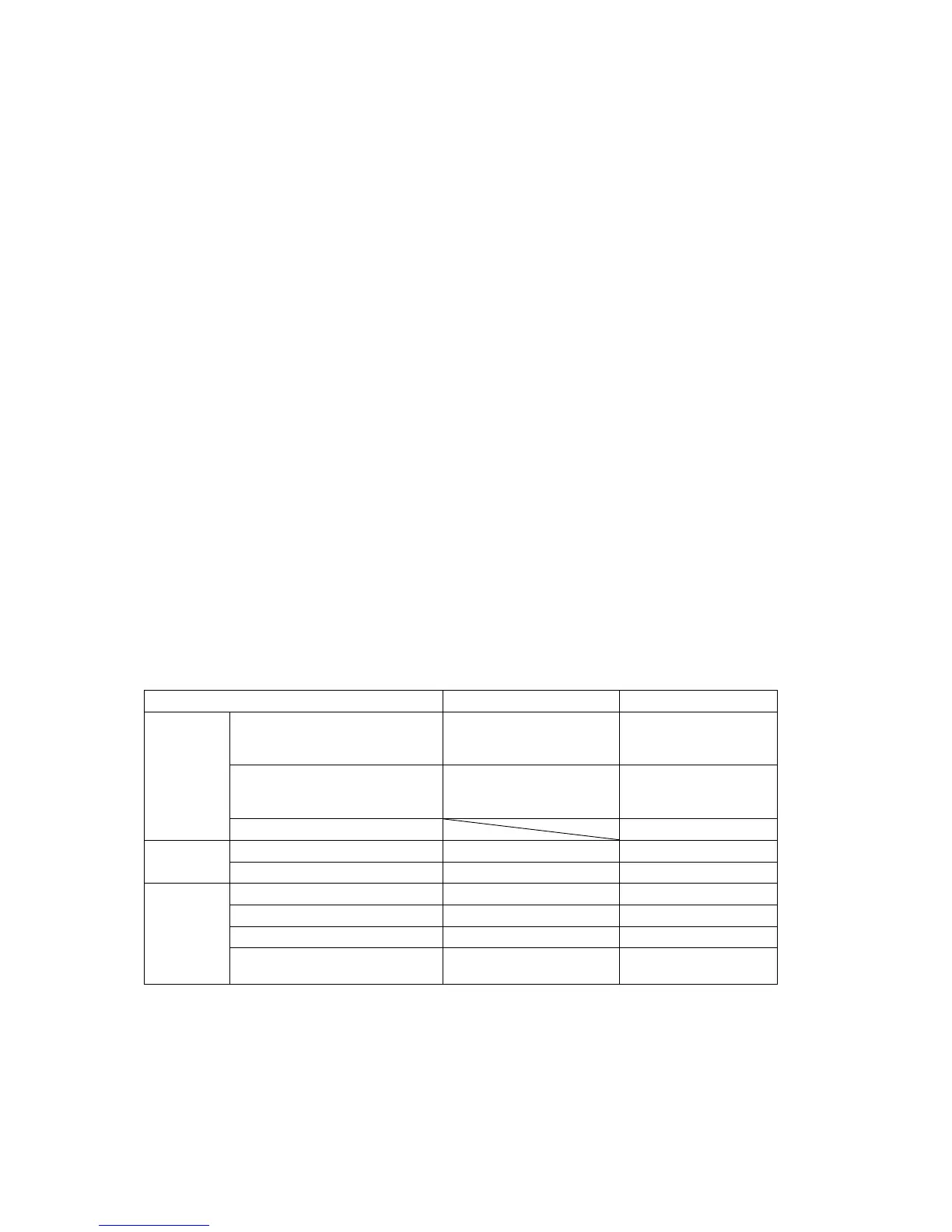

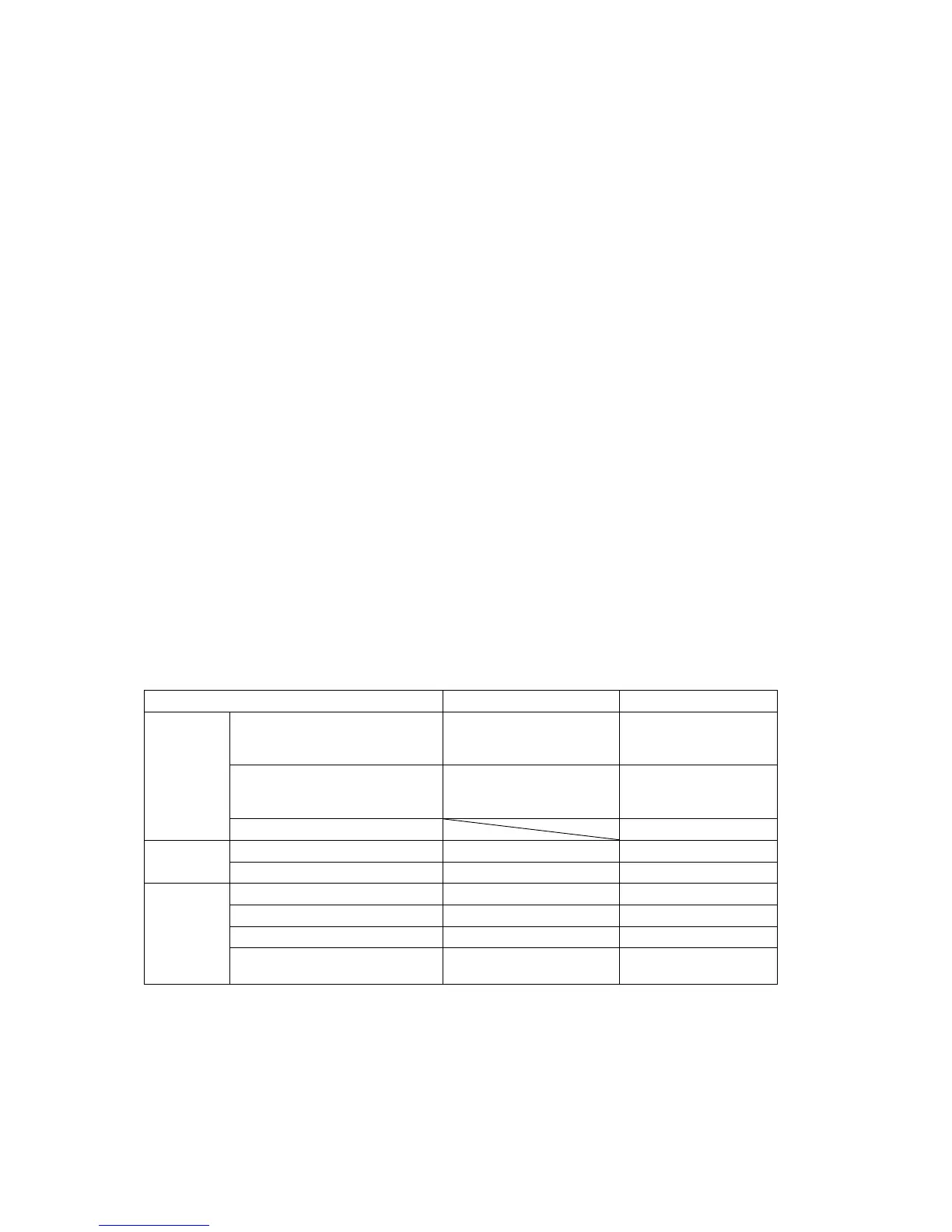

Preparation reference Unit:mm

Item Standard value Allowable limit

clearance of connecting

rod big end in right and left

direction

0.1-0.35 0.55

axial clearance of

connecting rod big end in

vertical angle

0-0.008 0.05

Crankshaft

vibration 0.1

Thickness of wearing plate 2.9-3 2.6

Clutch

Length of pressure spring 29.4-30.6 29.0

Bore diameter of shift fork 7.825-7.845 7.91

Thickness of shift fork 3.95-4.05 3.9

Outer diameter of shift drum 41.8-42 41.75

Shift

mechanism

Locked groove width of shift

drum

6.05-6.15 6.3

Tools

Multiple use fixer Clutch spring compressors

Driver's perch Box spanner

Guide rod Bearing driver

Loading...

Loading...