pag. 42

Release 00 - 02/2008

Engine WBE 0701-WBE 0704

Service manual

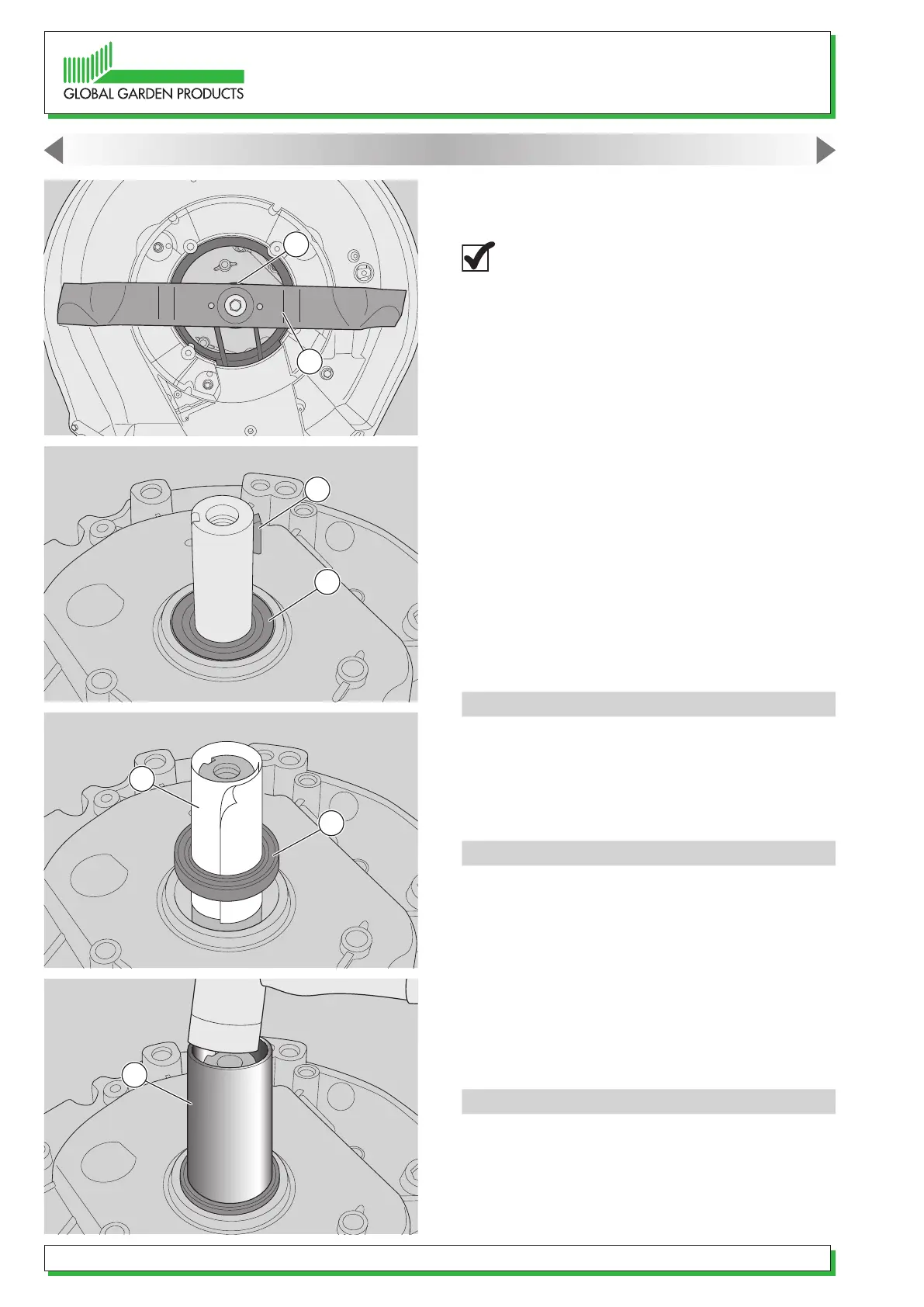

13. ENGINE BLOCK - External operations

13.8. Replacing the lower compression ring of the

engineshaft(sumpside)

NOTE - Before executing this operation di-

scharge all the oil from the bowl and rotate

180° the motor.

1 - Remove the blade (40) and hub (41).

2 - Take out the spline key (42).

3 - Use a thin screwdriver inserted under the sealing

lip to extract the oil seal ring (43).

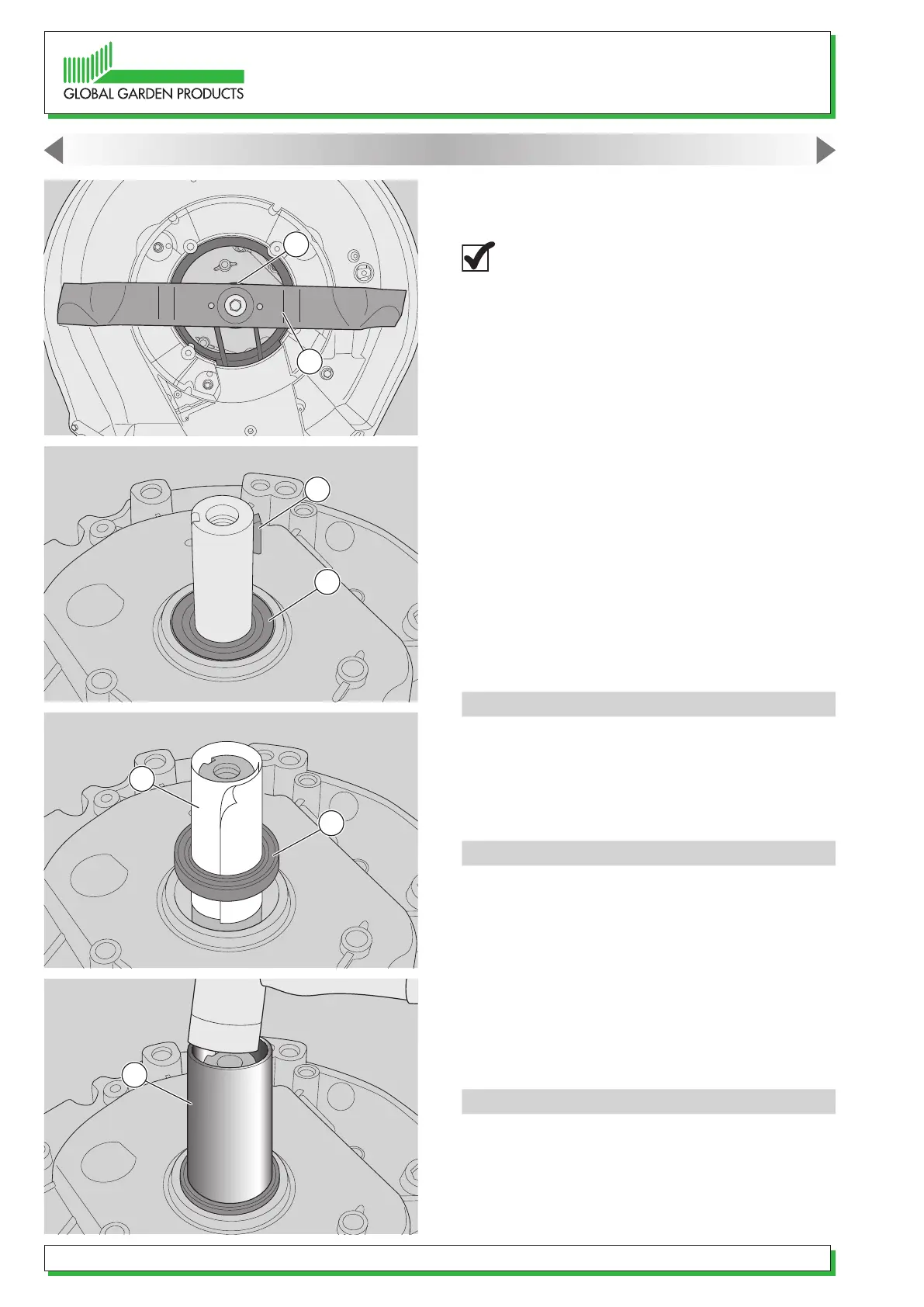

4 - Make a paper tube (44) around the shaft to

protect the sealing lip and insert the new ring (45)

so that it enters its housing.

5 - Complete the insertion with the help of a pipe

(46) of a diameter of approximately 30-35 mm.

Tightening torques

2 Spark plug tightening torque 16-18 Nm

6 Valve cover xing screws 8-12 Nm

13

Cylinder head screws 50-55 Nm

24 Flywheel xing nut 80-90 Nm

32

Screws small plate louver 8-12 Nm

Technical information

Compression Min. 4 bar

Inlet valve clearance 0,10-0,15 mm

Exhaust valve clearance 0,15-0,20 mm

Minimum inlet valve stem diameter 5,32 mm

Minimum exhaust valve stem diameter

5,27 mm

Min. inlet valve head rim thickness

0,5 mm

Min. exhaust valve head rim thickness

0,5 mm

Valve seat depth 1,8 mm

Minimum valve spring length 28.5 mm

Special equipment

3 Compression testing tool

21 Valve seat grinding tool

22 Valve grinder

42

43

45

44

46

41

40

Loading...

Loading...