Connecting Pump/Dispenser Inlet Pipes Installing Units on Island

Page 5-16 MDE-5427E Latitude

™

Installation Manual · July 2022

For Latitude installations:

• Selection of proper components mounted to the bottom of the strainer housing is critical in

maintaining the proper location of the shear valve groove of the shear valve to the base

plane of the dispenser. You must follow the shear valve manufacturer’s required

positioning for this groove.

• A check valve is strongly recommen

ded. When installed, Gilbarco recommends using

N23274, which is approximately 2-1/2-inch long and can take the place of the close nipple

located above the union. Failure to install a check valve here can result in fuel sale

indication when the fueling position is activated with the nozzle closed and the check

valve back at the STP is leaking.

• A union is required above the shear valve.

• A Morrison male end Shear Valve [N23047 (Morrison # 636M-0200AV)]

can be used to

properly maintain the position of the shear groove. The installer must verify if other

manufacturer’s shear valves will ensure proper positioning of the shear groove as per their

specifications.

• Not all double poppet shear valve models or styles will fi

t the Latitude unit.

• Other combinations of unions, chec

k valves, and shear valves may be possible and still

maintain proper location of the shear groove.

• Removal of a strainer from the system will void warranty

.

Follow the shear valve manufacturer

’s instructions for installation procedures, testing, and so

on.

• Install the shear valve on each

product inlet pipe.

Note: Latitude dispensers require 1-1/2-inch male

top shear valves. Gilbarco strongly

recommends using double poppet shear valves that shut off flow from both storage

tanks and internal to the unit (for example, OPW #10BHMP or

Exxon

®

- OPW # 10RMSP). The Latitude dispensers use 2-inches male top shear

valves (for example, Morrison Bros. 2” 636 m).

• For Latitude units, install the shear valve

on each 2-inch inlet and outlet.

• Install a shear valve on the master dispenser satellite outlet and at sat

ellite inlet.

• Do not mount the shear valve upside down.

• Ensure that the valve linkage is ac

cessible and has no interference to open or close from

other piping, structure, or components.

Note: The dispenser product inlet pipes must be

aligned with the shear valve. Do not

restrict shear valve linkage with pipes, braces, and so on.

• Test shear valve operation.

• Close the shear valve until equipme

nt start-up. Cap the inlet pipe. This prevents dirt and

other particles from entering the product line. It also prevents fuel spillage.

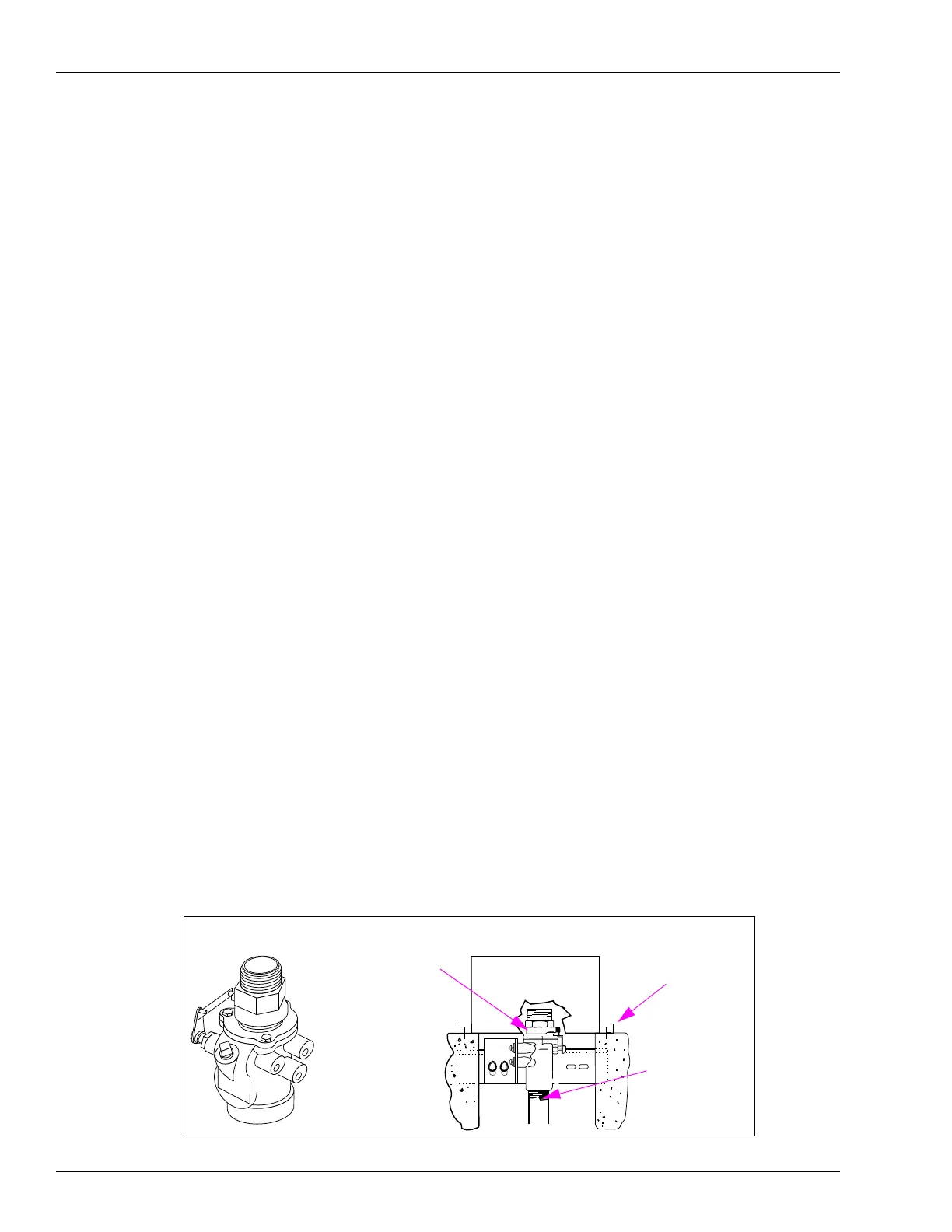

Figure 5-11: Shear Valve

Shear Valve

Shear valve groove location must be

flush to island surface ± 0.75’

Shear Groove

Island Surface

Product Inlet Pipe

Loading...

Loading...