63

Water may lead to corrosion of parts in the refrigeration system.

Therefore, the indoor unit and tubing between the indoor and outdoor unit must be leak tested and

evacuated to remove any non-condensable and moisture from the system.

Air purging with vacuum pump

⚫ Preparation

Check that each tube (both liquid and gas side tubes) between the indoor and outdoor units have been

properly connected and all wiring for the test run has been completed. Remove the service valve caps

from both the gas and the liquid side on the outdoor unit. Note that both the liquid and the gas side

service valves on the outdoor unit are kept closed at this stage.

⚫ Pipe length and refrigerant amount:

Note: Pipe length means the liquid side of each indoor unit.

⚫ When relocate the unit to another place perform evacuation using vacuum pump.

⚫ Make sure the refrigerant added into the air-conditioners liquid form in any case.

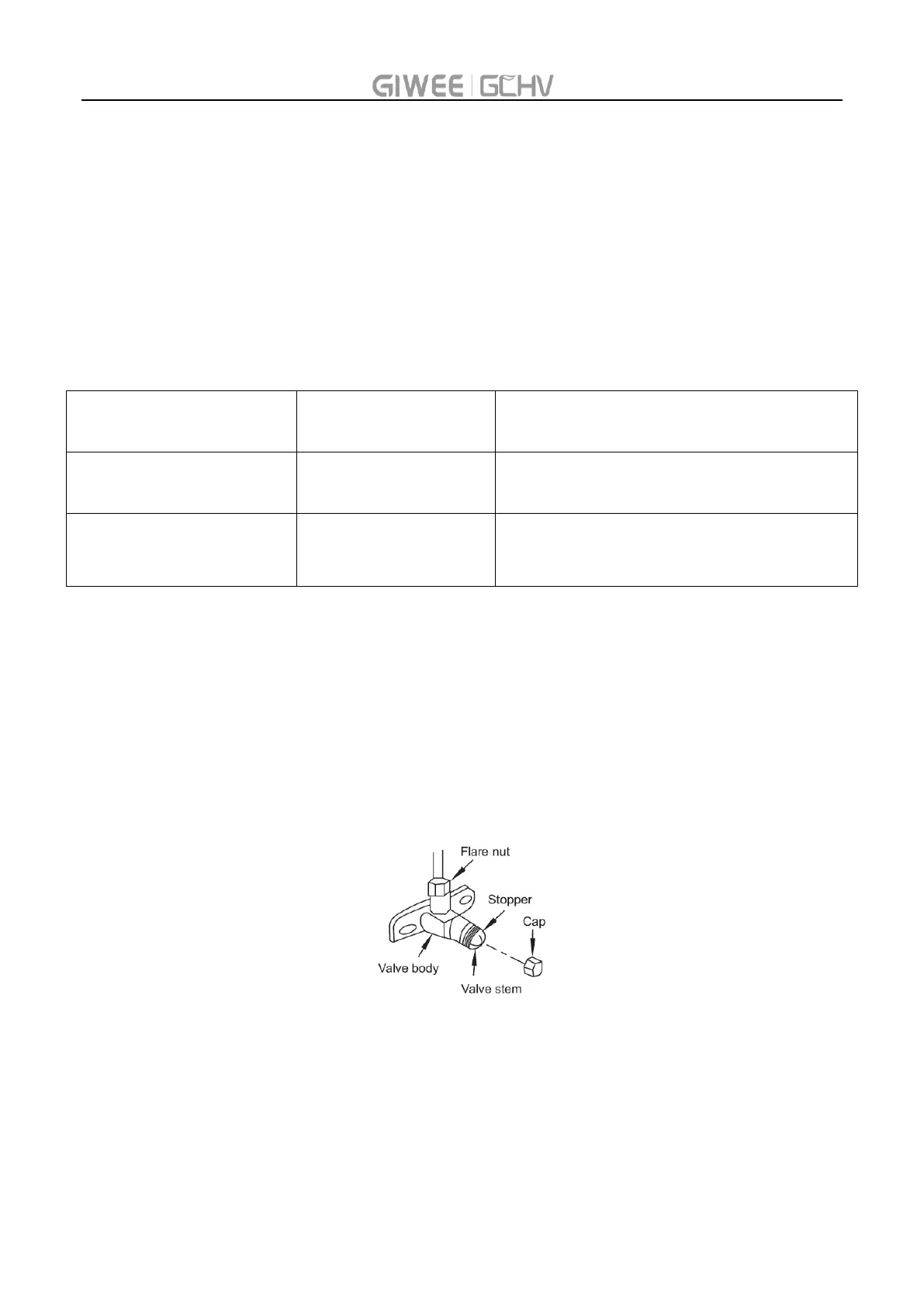

Caution in handling the stop valve

⚫ Open the valve stem until it hits against the stopper. Do not try to open it further.

⚫ Securely tighten the valve stem cap with a spanner or the like.

⚫ Valve stem cap tightening torque.

When using the vacuum pump

⚫ Preparation

(For method of using a manifold valve, refer to its operation manual.)

1. Completely tighten the flare nuts, A, B, C, D, connect the manifold Valve charge hose to a charge

port of the low-pressure valve on the gas pipe side.

2. Connect the charge hose connection to the vacuum pump.

Loading...

Loading...