Book No.: 95-0014-0000/A OPERATOR

Issue: 06 HANDBOOK

Page 13 of 30

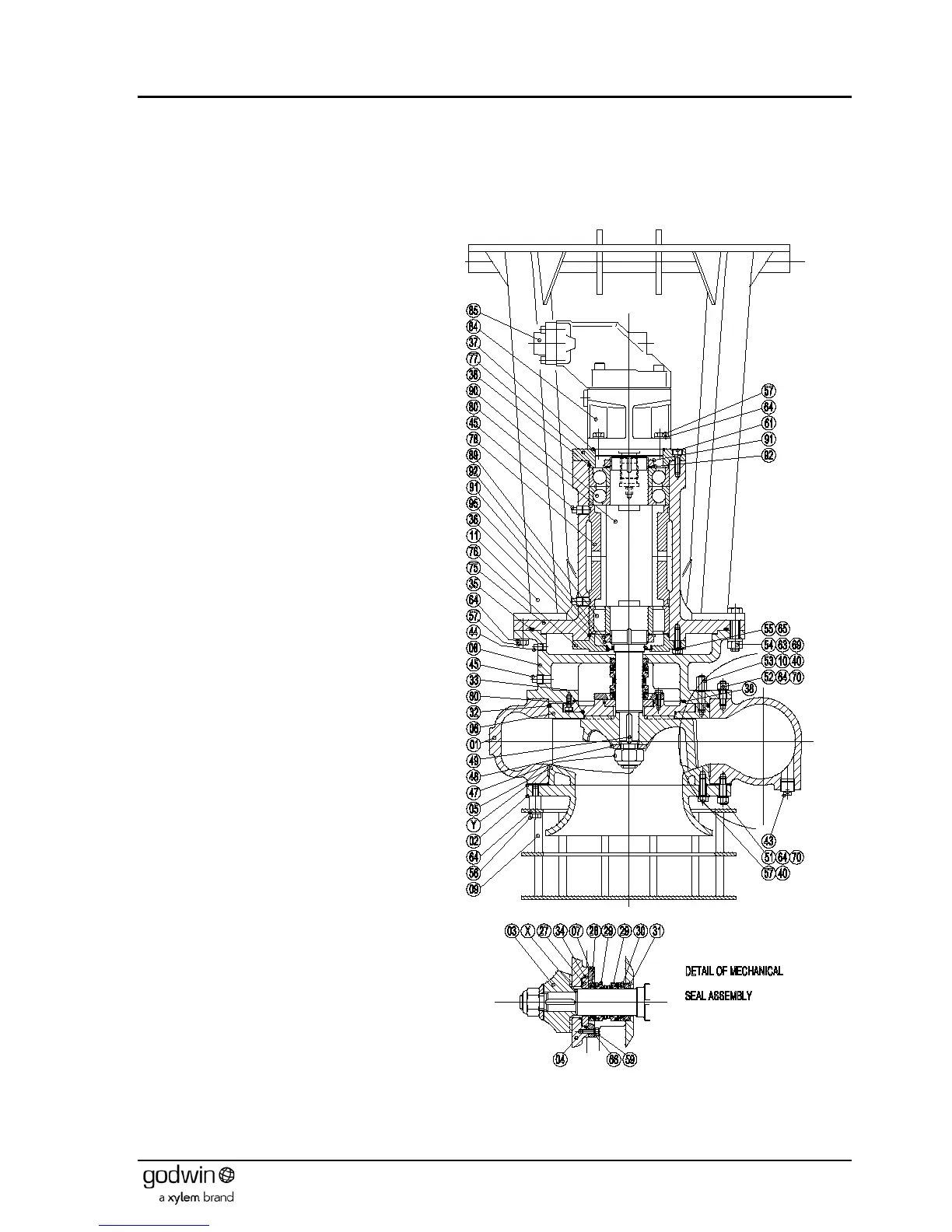

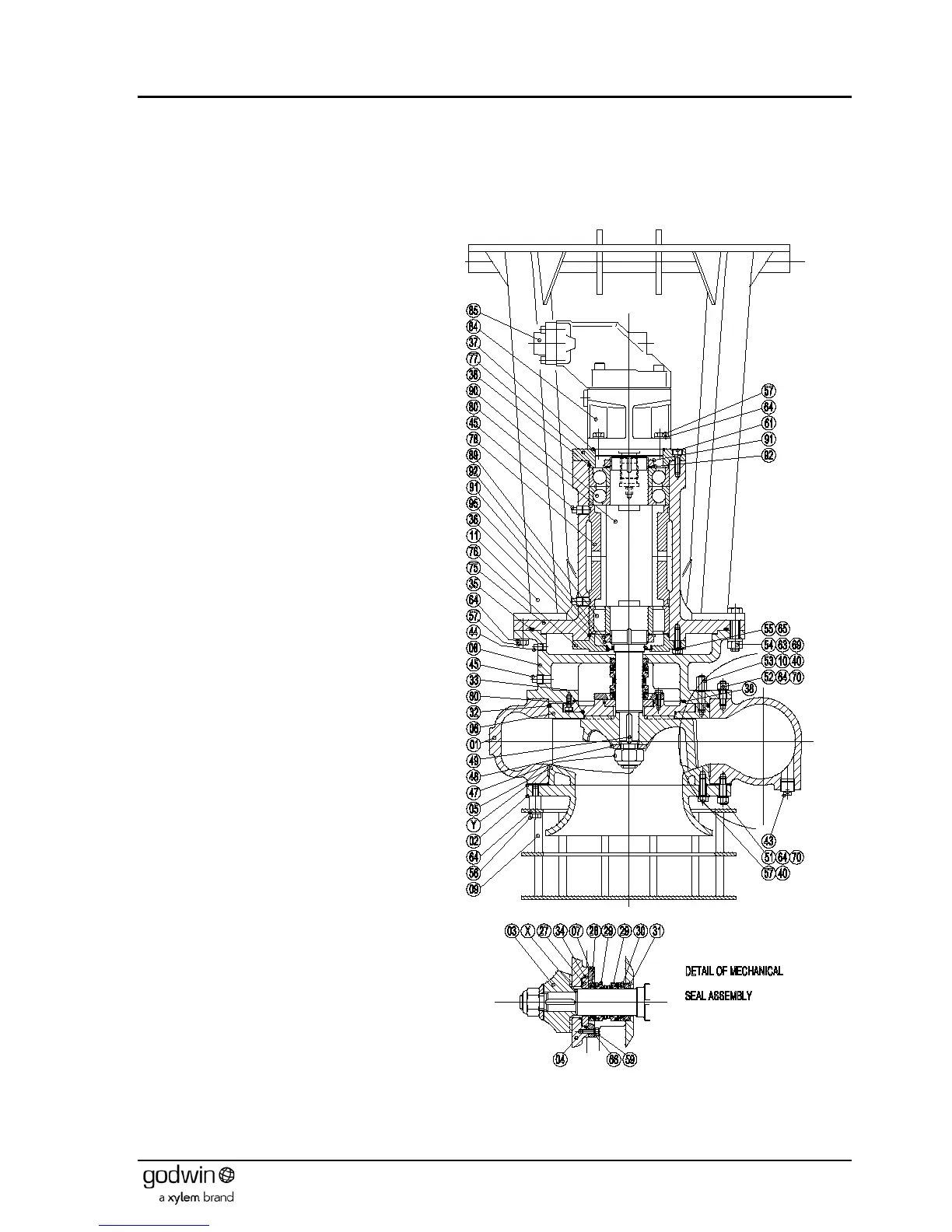

7.3 HS150HH, HS200-SG, HS200 & HS250 pumps

Note that dismantling and reassembly procedures refer to the item numbers in the illustration and are correct for a

directly corresponding build. However because of the number of possible build configurations some interpretation of the

diagram will be necessary for other pump variants. Some additional illustrations have been included to aid in this

purpose.

7.3.1 Dismantling

1. If not previously done remove the plugs (45)

from the bearing bracket (75) and drain the

oil. Remove the plug (44) from the adaptor (8)

and drain any leakage.

2. Remove the plug (45) from the adaptor and

drain the seal housing of oil.

3. Undo set screws (56) holding the strainer (9)

to the pump body (1). Remove strainer.

4. Release the nuts (70) holding the bearing

bracket, adaptor, wear plate and impeller

assembly to the pump body (1). (NOTE.

These are the nuts on the larger PCD. The

screws on the smaller PCD retain the wear

plate to the bearing bracket).

5. Extract the bearing bracket assembly from the

pump body (1). The front cover (2) and wear

plate (5) may be removed from the body by

releasing the nuts (70). The front wear plate

can be removed from the front cover by

removing the screws (57).

6. Place a bar through the vanes of the impeller

(3) to lock it in position and prevent rotation.

Unscrew (RH thread) and remove the impeller

retaining nut (47) and washer (48). Note that

the nut has a nylon insert that provides a self-

locking function. The nut will therefore remain

stiff to turn until this nylon insert is clear of the

shaft.

7. Pull the impeller (3) off the shaft (80) and

remove the key (49). Four off M8 tapped

jacking screw holes are provided in the boss

of the impeller if required to aid in its removal.

Shims (15, 16, 17 & 18) may be found on the

shaft behind the impeller. These have been

used to achieve the required rear clearance.

Keep a check on quantity and thickness for

comparison purposes when rebuilding.

8. Release the nuts (10) holding the rear wear

plate (6) to the bearing bracket assembly.

Remove the wear plate.

9. Undo and remove the socket head cap

screws (60) holding the inner wear plate and

seal carrier (4) to the adaptor (8). Remove

this inner wear plate with care as it carries the

seal seat (27). Once removed, the seal seat

can be removed from the wear plate by

undoing the screws (59) to release the seal

clamping plate (7).

10. The mechanical seals (29) are now exposed

and can be released by undoing their

clamping screws. Ensure that the screws are

fully retracted before moving the seals to

ensure that they do not mark the shaft during

removal. Slide the mechanical seals (2 off 29)

off the shaft (80) and extract the seal seat from

the adaptor (8).

Figure 10 Typical HS200 pump

Loading...

Loading...