OPERATOR Book No.: 95-0014-0000/A

HANDBOOK Issue: 06

Page 24 of 30

7.5.2.3 ADJUSTING IMPELLER FRONT CLEARANCE

Unscrew and remove the impeller cap screw and flat washer.

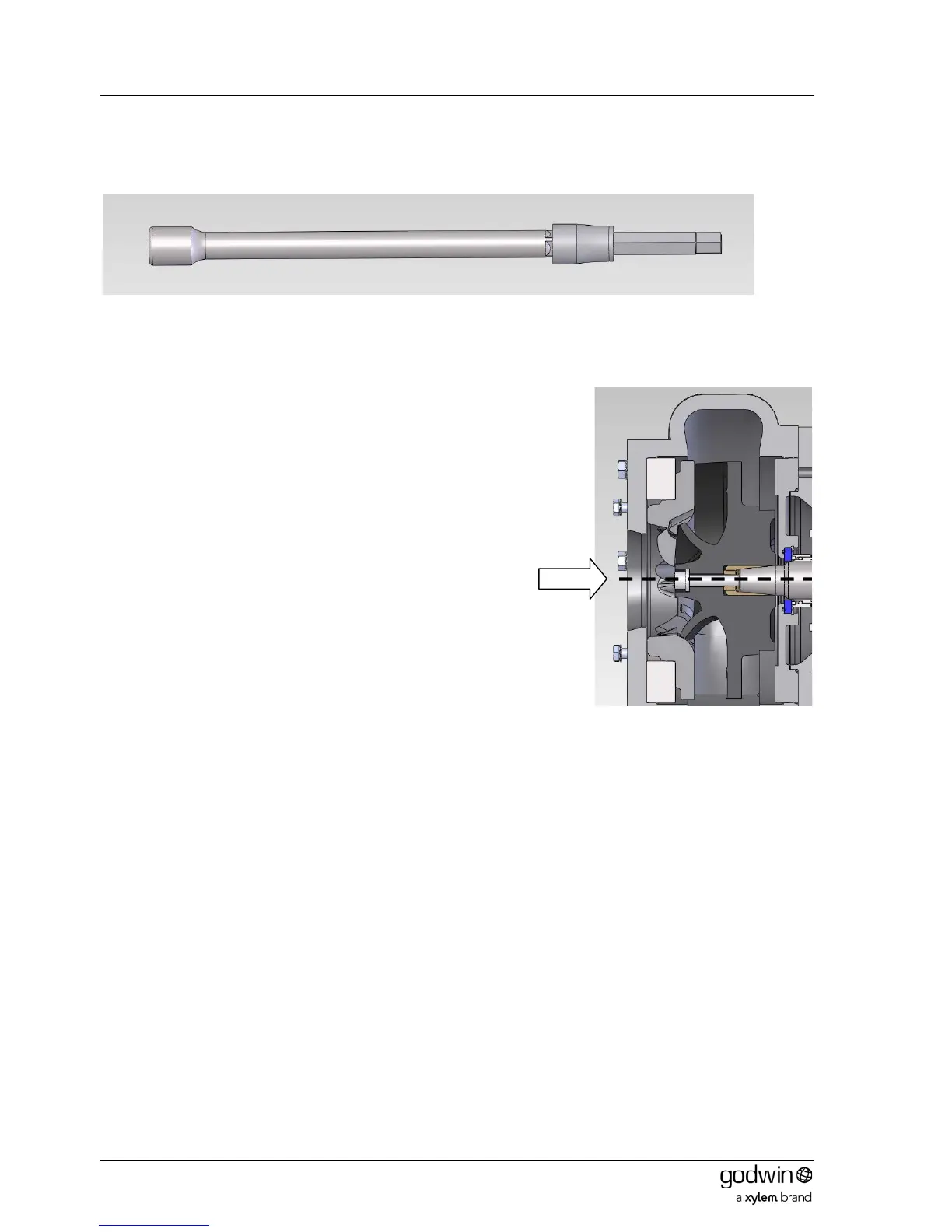

Using the Hexagon head (Allen bit) 12mm x 65mm long with extension bars (Figure 30 if needed) turn the adjustment

screw clockwise by hand until the impeller firmly makes contact with the wear plate (insert ring).

Figure 30 Hexagon head (Allen bit) and extension bar

Remove the Hexagon head (Allen bit), reach into the pump inlet and check the impeller cannot be rotated from this

position by hand.

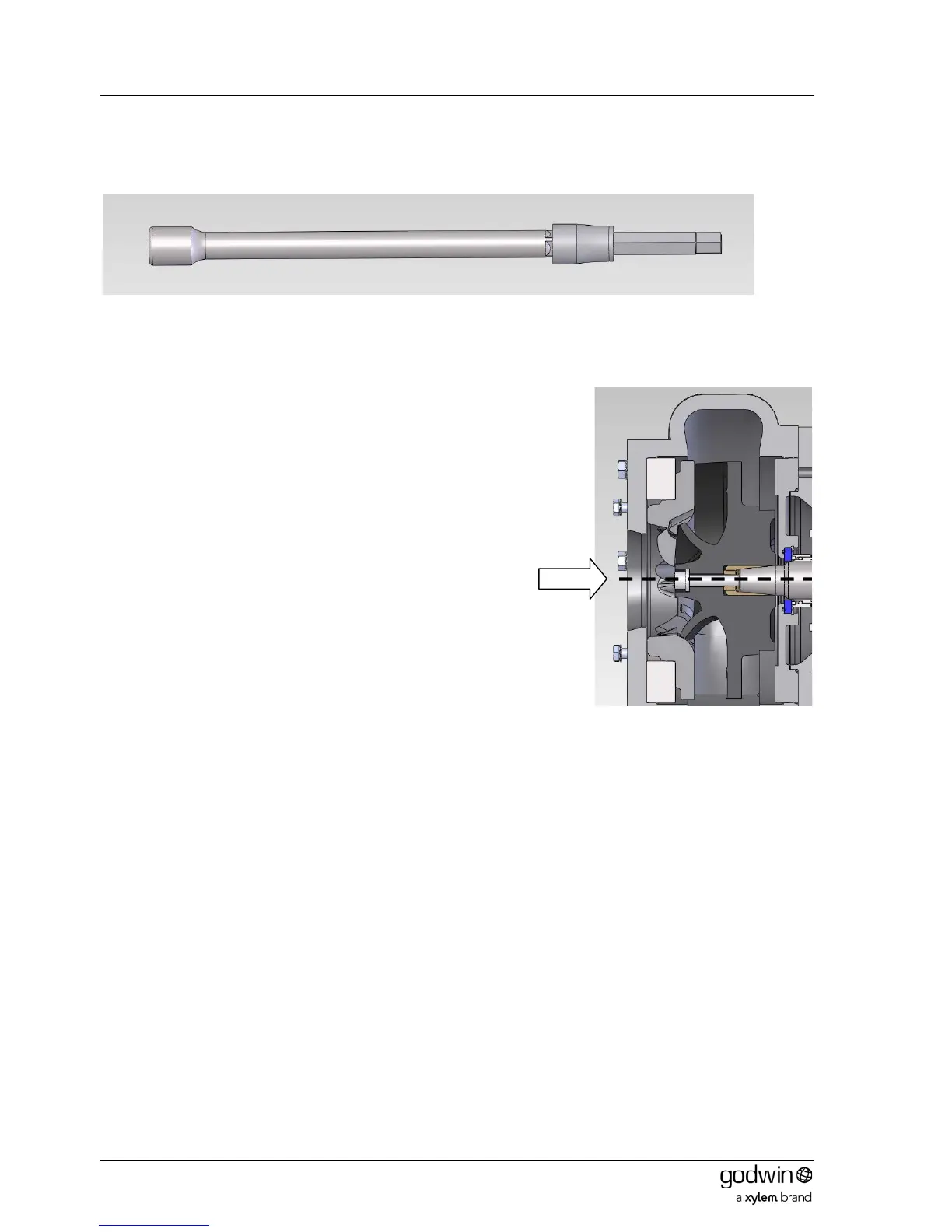

Insert the anti-rotation bar through the access plug in the pump body to

prevent the impeller rotating.

Fit the lubricated impeller cap screw and flat washer.

Tighten the impeller cap screw to the correct torque using a torque

wrench, and then turn it an extra 1/8 turn (45°) with a wrench or bar.

(Check cap screw size and see Section 10.4

Table 2 for values).

Using feeler gauges reach into the pump inlet and measure the

available impeller to wear plate (insert ring) clearance.

The minimum acceptable running clearance is 0.2mm (0.008”)

Important: Remove the anti-rotation bar and replace access plug in the

pump body.

Figure 31 Cross-section of pump inlet

Loading...

Loading...