OPERATOR Book No.: 95-0014-0000/A

HANDBOOK Issue: 06

Page 4 of 30

3 SAFETY PRECAUTIONS

WARNING. ALL ITEMS IN THIS SECTION, IF NOT STRICTLY OBSERVED, COULD RESULT IN SEVERE

PERSONAL INJURY OR LOSS OF LIFE.

Only use lifting equipment of suitable capacity for the size and weight of the equipment being lifted. The pump units are

designed for lifting by wire rope in use or slings around the workshop.

The equipment must always be lifted using safe working practices and in accordance with any local and national

guidelines or statutes. If in doubt, consult Xylem Dewatering Solutions or a local lifting expert.

Whilst lifting the unit keep personnel well away and never allow people underneath.

Personnel working on the pump must always wear clean, correctly fitting clothing and safety footwear. Clothing

impregnated with oil or fuel can constitute a health hazard through prolonged contact with the skin and may also

constitute a fire hazard.

Check the type of liquid the pump has been used for before working on them. Residues could be hazardous to your

health. If in doubt, flush thoroughly with clean water before commencing work.

Rotating equipment presents a hazard in itself. Alert surrounding personnel before starting and post notifications whilst

in operation.

Moving parts are guarded to protect you. Guards removed for maintenance must be replaced before starting the pump.

Never insert anything into the pump body whilst the pump is running and the delivery hoses are disconnected.

Where connections are flanged, use all flange bolt holes and ensure the correct bolt size and quality is utilised when

connecting suction and delivery hoses.

Where connections are threaded, ensure the threads are sound before use and protected from damage if left

unconnected during storage or transportation.

Although the pump can handle solids up to the size indicated in the Technical Data section of this manual, larger or

irregular solids may cause blockage with consequent damage to pump components.

Always allow adequate ventilation for the pump driver. Diesel engines require air for both combustion and cooling.

Electric motors require air for cooling purposes. This air must never be allowed to recirculate.

Be aware of burn and fire risks from items such as diesel engine exhaust pipes and silencers. Never place flammable

items around the unit.

Diesel engines exhaust and some of its constituents are known in the State of California to cause cancer, birth defects

and other reproductive harm.

Liquid pressure may still be present even after shutdown of the pump. Particular attention should be paid to delivery

lines that are long, or rise through any height, as these can contain large volumes of liquid. These lines must be

isolated and drained down before commencing work. Sudden release of this liquid can cause serious injury to an

operator either directly or indirectly through the rotational motion it can induce.

Never run the pump above its maximum speed.

Wear protective gloves when handling the equipment. There may be sharp metal edges.

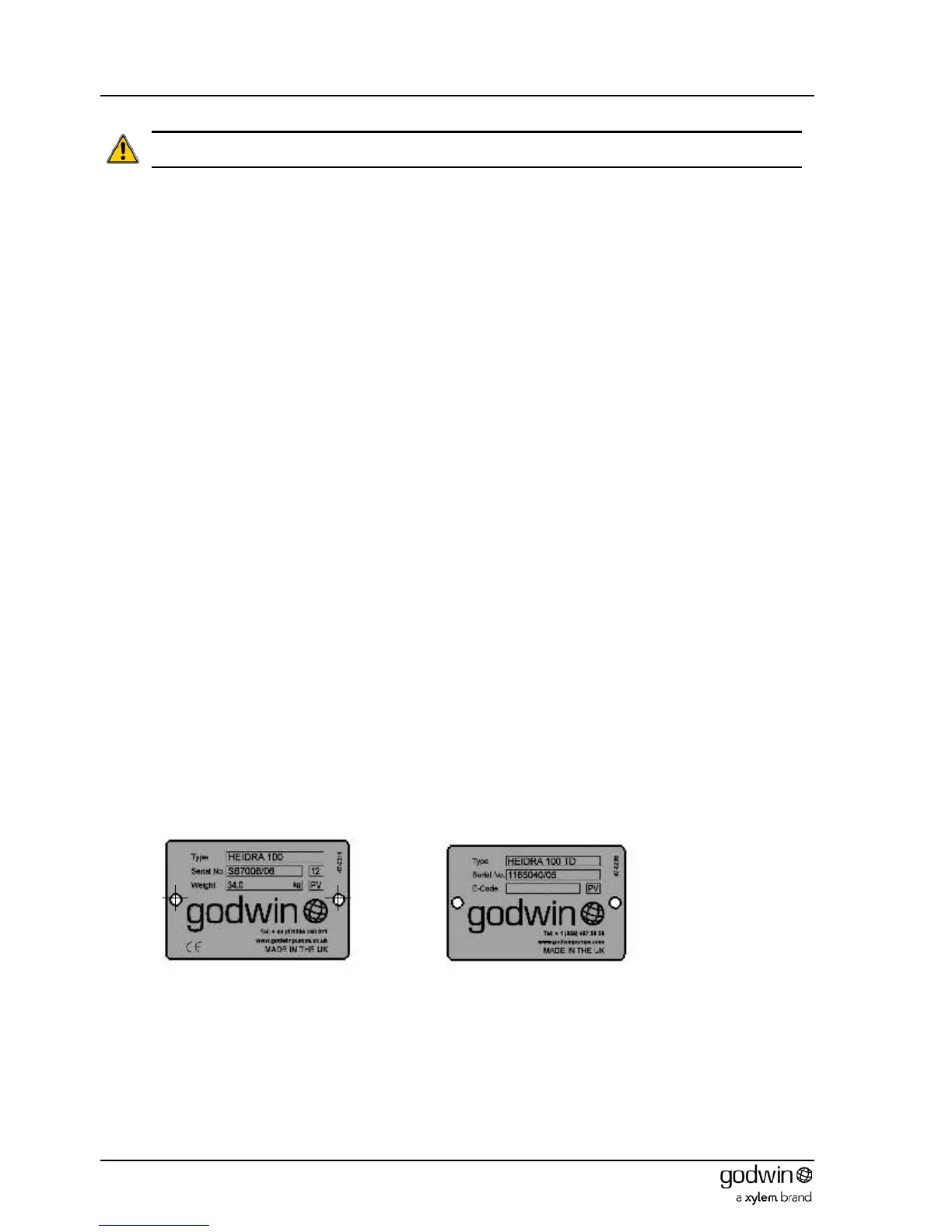

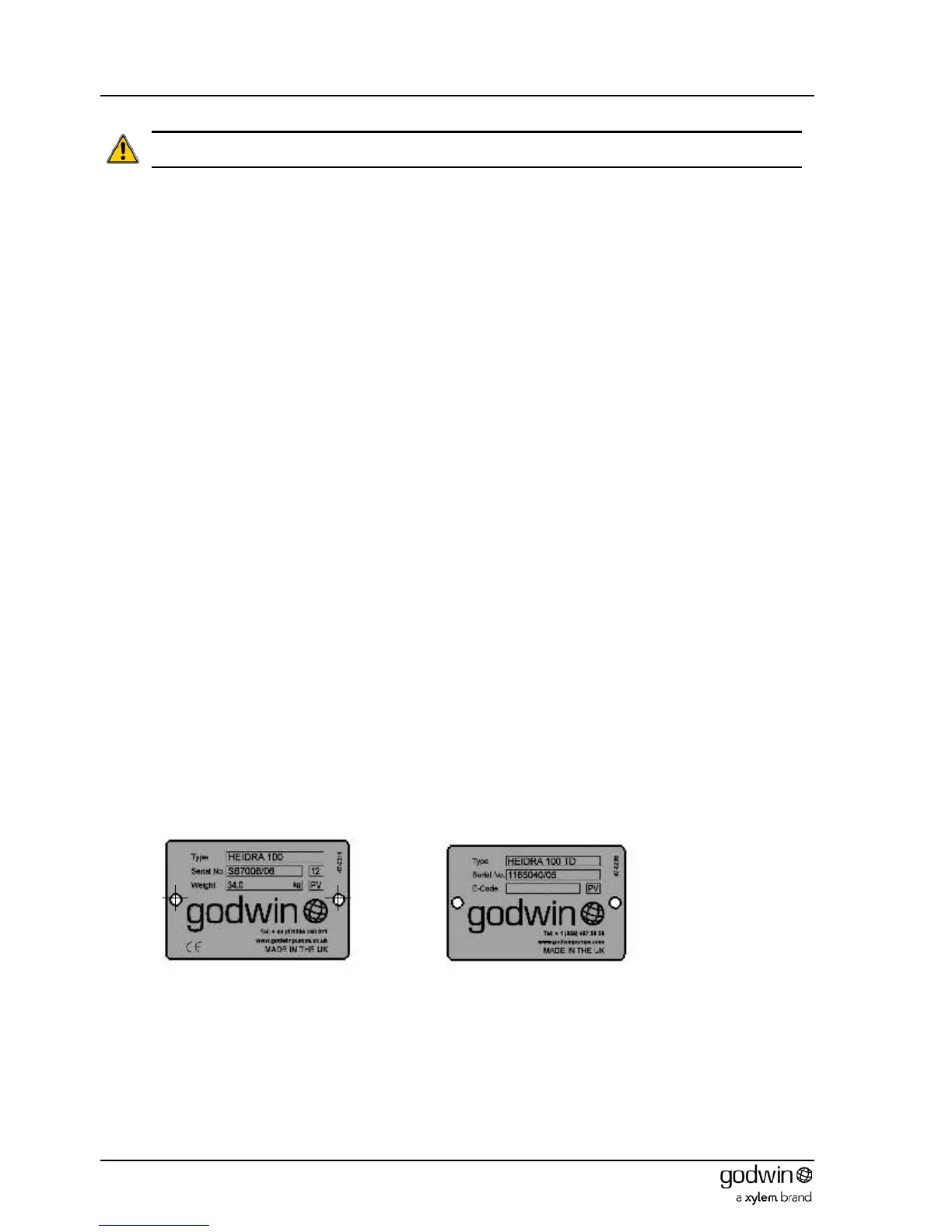

4 IDENTIFICATION

Every pump unit has a nameplate similar to one of those shown below. This nameplate lists the serial number and type

of the pump. These numbers must be quoted in any enquiry for spares or service.

Loading...

Loading...