OPERATOR Book No.: 95-0014-0000/A

HANDBOOK Issue: 06

Page 20 of 30

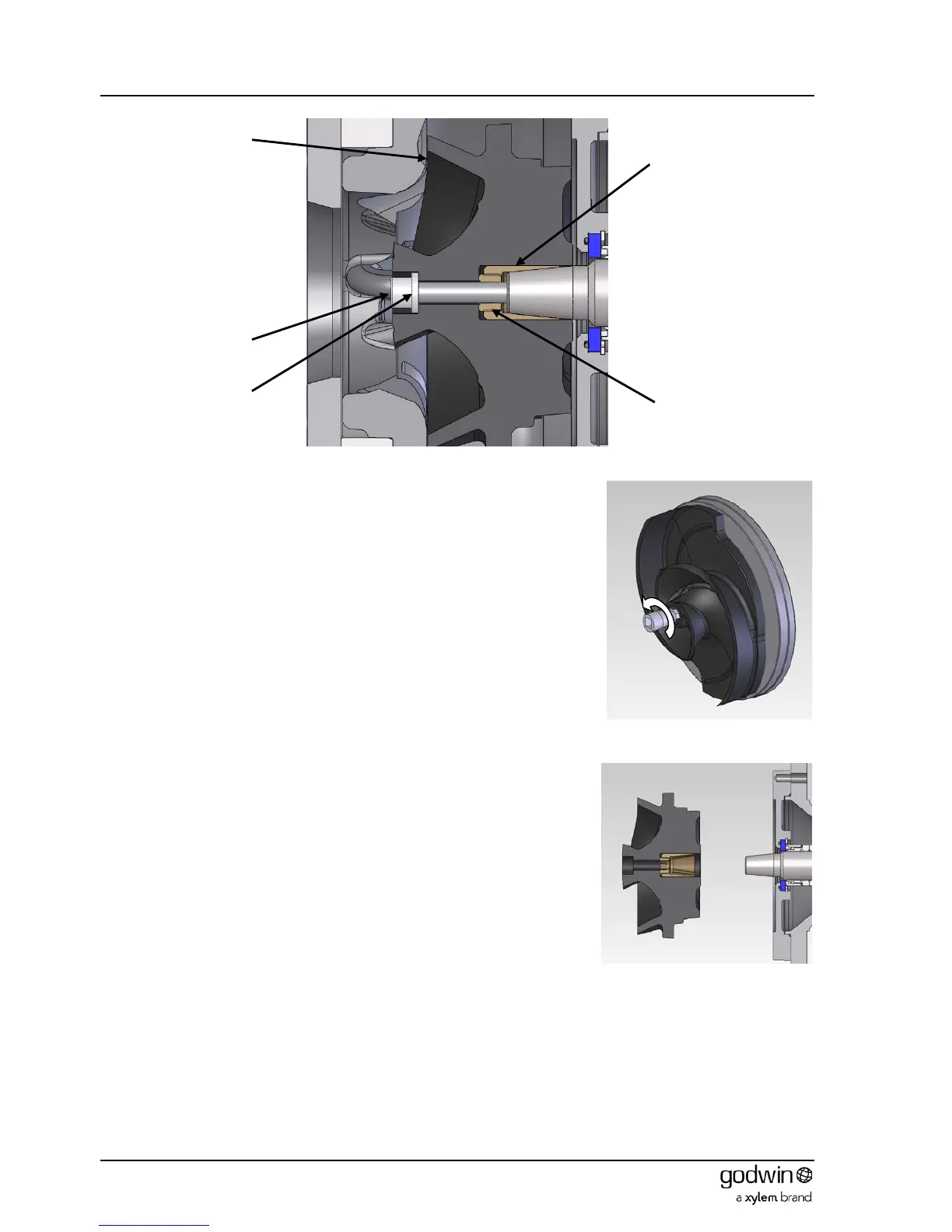

Figure 17 Typical HS100NC & HS150NC cross sectional view

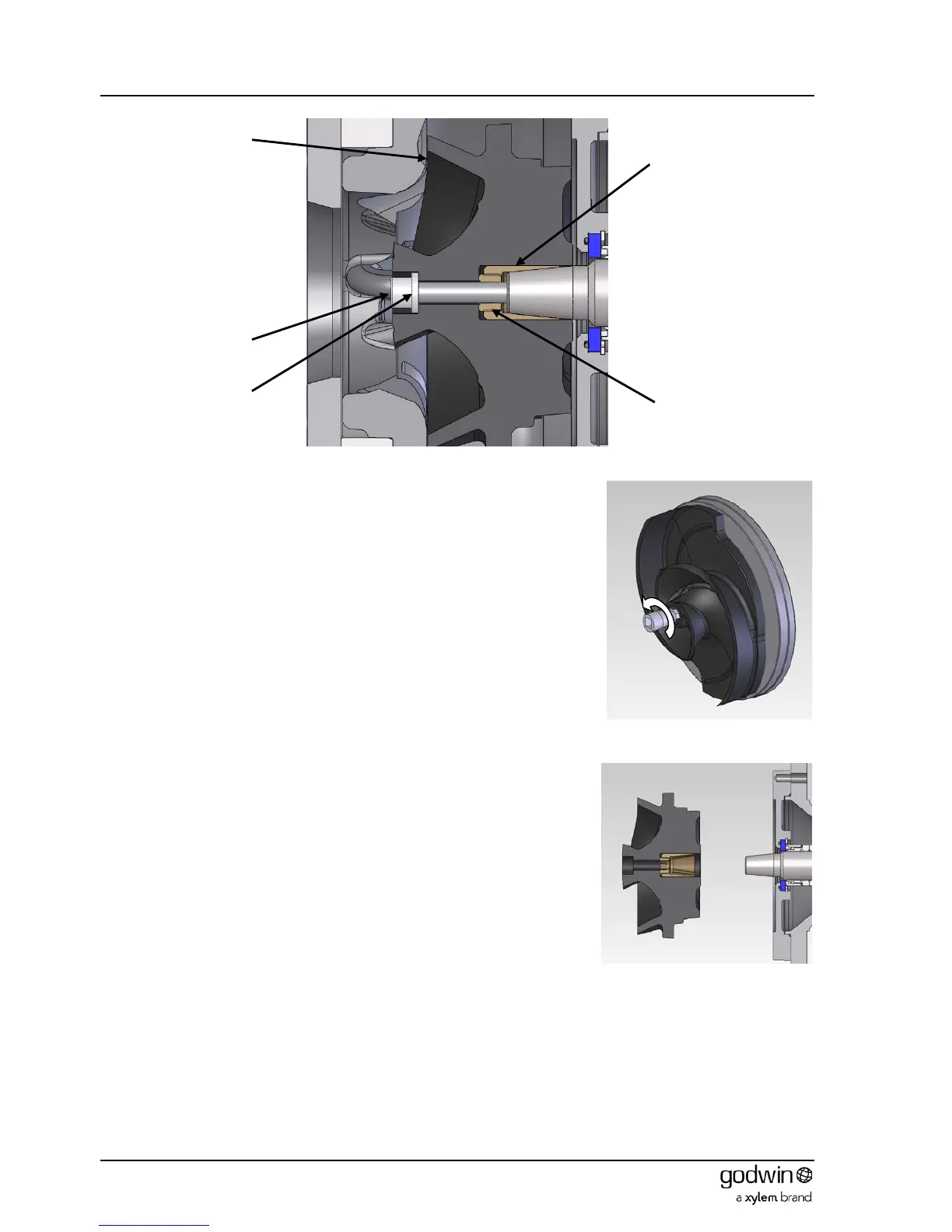

To break the friction fit between the impeller sleeve and the shaft, the adjustment

screw is turned anticlockwise (it is left hand threaded -Figure 18 ) using the 65mm

long Allen key (Figure 15). Turn sufficiently until it contacts the shaft and just breaks

the engagement.

Refit the impeller washer and screw hand tight as a security measure. This will

ensure that the impeller is retained on the shaft when the bearing bracket assembly

is removed from the volute.

The impeller is then removed from the shaft be undoing and removing the hand

tight impeller screw and washer. The impeller , impeller sleeve and adjustment

screw can then be removed.

All remaining dismantling procedure follow those in section 7.2.1.

Loading...

Loading...