WPE

OF

PROBLEM

:ondition

B

(continued)

Both lamps

off

REFER

TO

THE WIR-

-.

~

PAGE 14 TO IDENTIFY

TP POINTS.

ING

DIAGRA~J

O

N

:ondition

C

Clear lamp off

Red lamps

on,

Unplug

sprayer!

WHAT TO

CHECK

If

check

is

OK.

00

to the next check.

1. Checkelectrical supply. Connectvoltmeter

to

electrical outlet. Meter should read

190-250

Volts

2.

Check power supply

to

circuit board with

sprayer turned

ON.

Measure voltage at

TP1 and TP2. Meter should read 190-250

Volts.

See page 26.

3.

Check all terminals and wires for damage

or loose

fit.

4.

Checkmotorthermalcutoutswitch..Unplug

sprayer. Allow motor

to

cool. Disconnect

TP10. Use ohmmeter

to

check continuity.

motor thermal switch leads at

TP9 and

cool.

Switch should be closed when motor

is

-.

5.

Check microswitch

(306).

With no fluio

pressure

in

the pressure control, discon

-

nect wires TPlSandTP19. Checkcontinu-

ity across switch terminals with an ohmrne-

press actuator button.

An

audible "clickin-

fer. Switch contact should be closed. De

-

dicates the contacts have opened. Ohm-

6.

Check circuit board (118) by substituting

with a aood board. See Daoe 26.

1.

Checkcircuit board

(1

18) by removing from

box withoutdisconnecting wires; see page

26 for removal procedure.

I

WHAT TO

DO

If

check

is

not

OK.

refer to this column.

1.

Reset circuit breaker or replace outlet

fuse.lf circuit breaker or fuse continues

to

open, see

"

Electrical Short

"

, page 18.

2. Unplug sprayer. Check continuity

of

both

polesofON/OFFswitch(302)fromTPlto

faulty.

TP2 and

TP2

to

TP3. Replace switch

if

Check continuity of

RFI

filter (310) from

TP4 to TP6 and TP3

to TP5. Replace filter

if

faulty.

Check power supply cord (31 1) for

conti-

nuitv from TP5 to TP7 and TP6

to

TP8.

Replace cord

if

faulty.

Check for any loose connections.

3. Replace damaged terminals and recon

-

nect securely.

4.

Replace electric motor

if

switch does

not

close when motor is cool. See page 35.

5.

Replace ihe microswitch. See page 23.

6. Replace circuit board. See page

26.

1. Replace circuit board. See page 26.

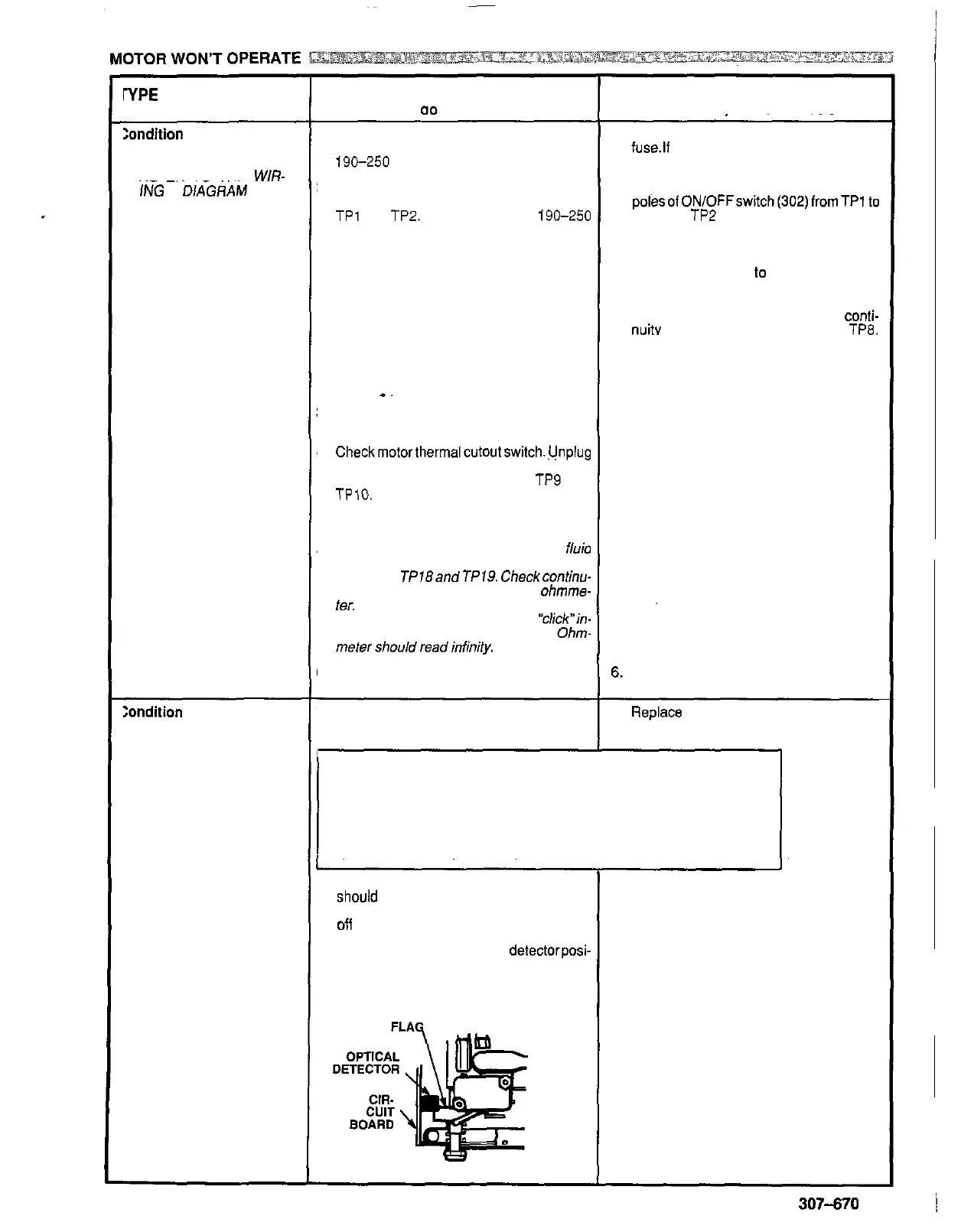

WARNING;

Removing the circuit board while still wired over

-

rides the

optical detector which could cause the sprayer to over

-

pressurize,

if

the

microswitch does

not

function properly. Turn the sprayer

on

ONLY long

enough

to

check lamp condition, then shut off immediately.

WARNING:

To reduce the risk of electric shock, handle board by edges

~

only!

Do

not allow any metal objects

to

come in contact with the board!

Plug in and turn

on

sprayer. Clear lamp

should be

on

now

-

removing the circuit

board over

-

rides the optical detector.

Turn

ofi

and unplug the sprayer.

2. Check bourdon tube flag and

detectorposi-

tion. Reinstall circuit board (see page 26).

Turn pressure setting to maximum; flag

should extend less than half way into opti

-

cal detector

slot

from the bottom.

2. Calibrate pressure control to see

if

that

corrects problem. See page 28.

If

not, replace bare pressure control box

(301). See page

27.

307-670

15

Loading...

Loading...