17

308-327

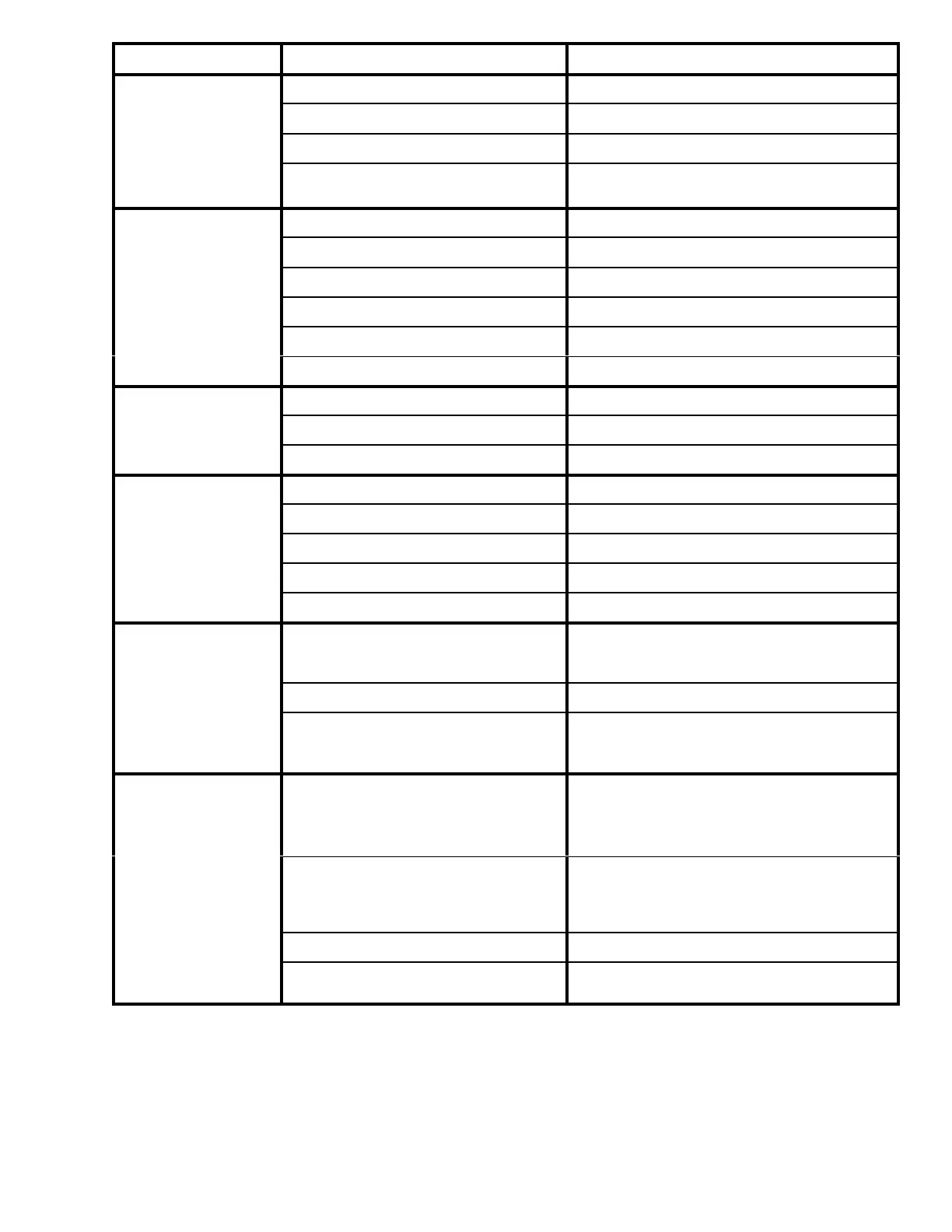

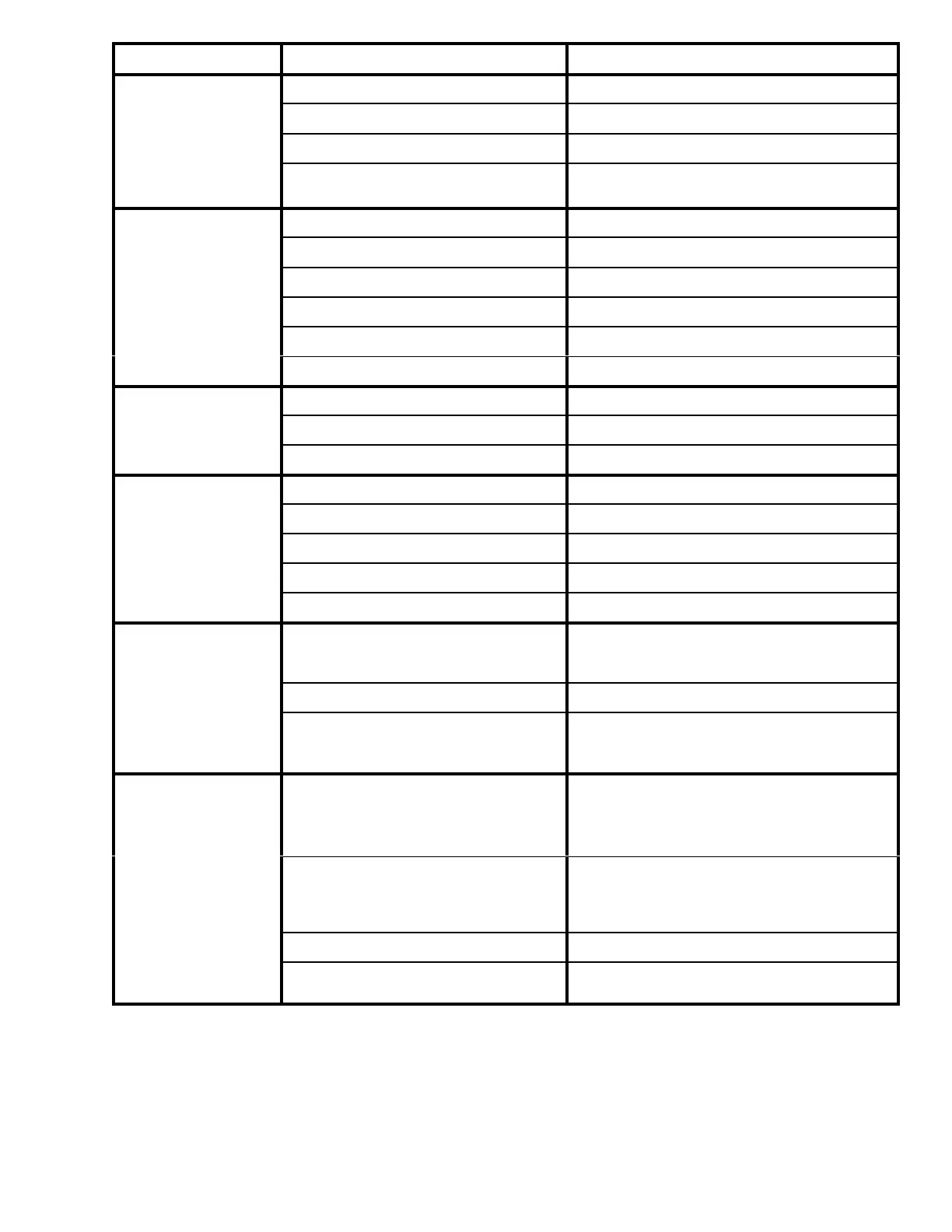

PROBLEM CAUSE SOLUTION

Displacement pump

Pump inlet screen clogged

Clean.

output low on upstroke

Piston ball check not seating Service piston ball check. See page 31.

Piston packings worn or damaged

Replace packings. See page 31.

Sleeve gasket in displacement pump is

damaged

Replace. See page 31.

Displacement pump

Pump inlet screen clogged

Clean.

output low on down

-

stroke or both strokes

Piston packings worn or damaged

Replace packings. See page 31.

Intake valve ball check not seating properly

Clean and service. See page 31.

Engine RPM too low

Increase throttle setting. See Step 1, page 13.

V–belt slipping

Replace V–belt.

Clutch worn or damaged

Replace. See page 21.

Paint leaks into wet-cup

Loose wet-cup

T

ighten just enough to stop leakage.

Throat packings worn or damaged Replace packings. See page 31.

Displacement rod worn or damaged

Replace rod. See page 31.

Low fluid delivery

Pump inlet screen clogged.

Clean.

Pressure setting too low

Increase pressure. See Step 1, page 13.

Engine RPM too low

Increase throttle setting. See Step 1, page 13.

Dirty outlet filter

, tip filter or tip

Clean.

Large pressure drop in hose Use larger diameter hose.

Spitting from gun

Air in fluid pump or hose

Check for loose connections at pump intake and

tighten. Then prime the pump. See

Startup

, page

12.

T

ip partially clogged

Clear.

Fluid supply is low or empty

Refill and prime the pump. See

Startup

, page 12.

Check fluid supply often to prevent running the

pump dry

.

Pump

is dif

ficult to prime

Air

leak Check all hose connections and tighten as

needed.

Reduce RPM and cycle pump as slowly as possi-

ble during priming.

Intake valve is leaking

Shut of

f pump and relieve pressure. Disassemble

and clean intake valve. Be sure ball seat is not

nicked or worn and that the ball seats well. Reas

-

semble.

Worn packings

Repack the pump. See page 31.

Fluid is too thick

Thin fluid according to supplier

’

s recommenda

-

tions.

Loading...

Loading...