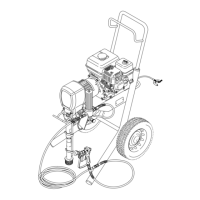

Pinion

Remove the Pinion Housing

WARNING

To

reduce the risk of serious injury

, always follow

the

Pressure Relief Procedure W

arning

on page

16 before repairing the sprayer

.

NOTE:

Refer to Fig. 8 for Steps 1 to 2.

1.

First remove the two bottom screws (3) and

lockwashers (4) from the clutch housing (222), and

then remove the top three screws and

lockwashers.

2.

Pull the pinion housing (219) away from the clutch

housing (222). The armature (212b) will come out

still attached to the clutch housing. Pull the arma

-

ture of

f the hub inside the pinion housing.

NOTE:

T

o disassemble the pinion, go to

Repairing

the Pinion. T

o disassemble more of the sprayer

, go to

page 21. T

o reassemble the sprayer from this point,

skip ahead to

Reassembly

, page 24, Steps 3 and 4.

Fig. 8

02695

219

212b

222

See

Fig. 9

4

3

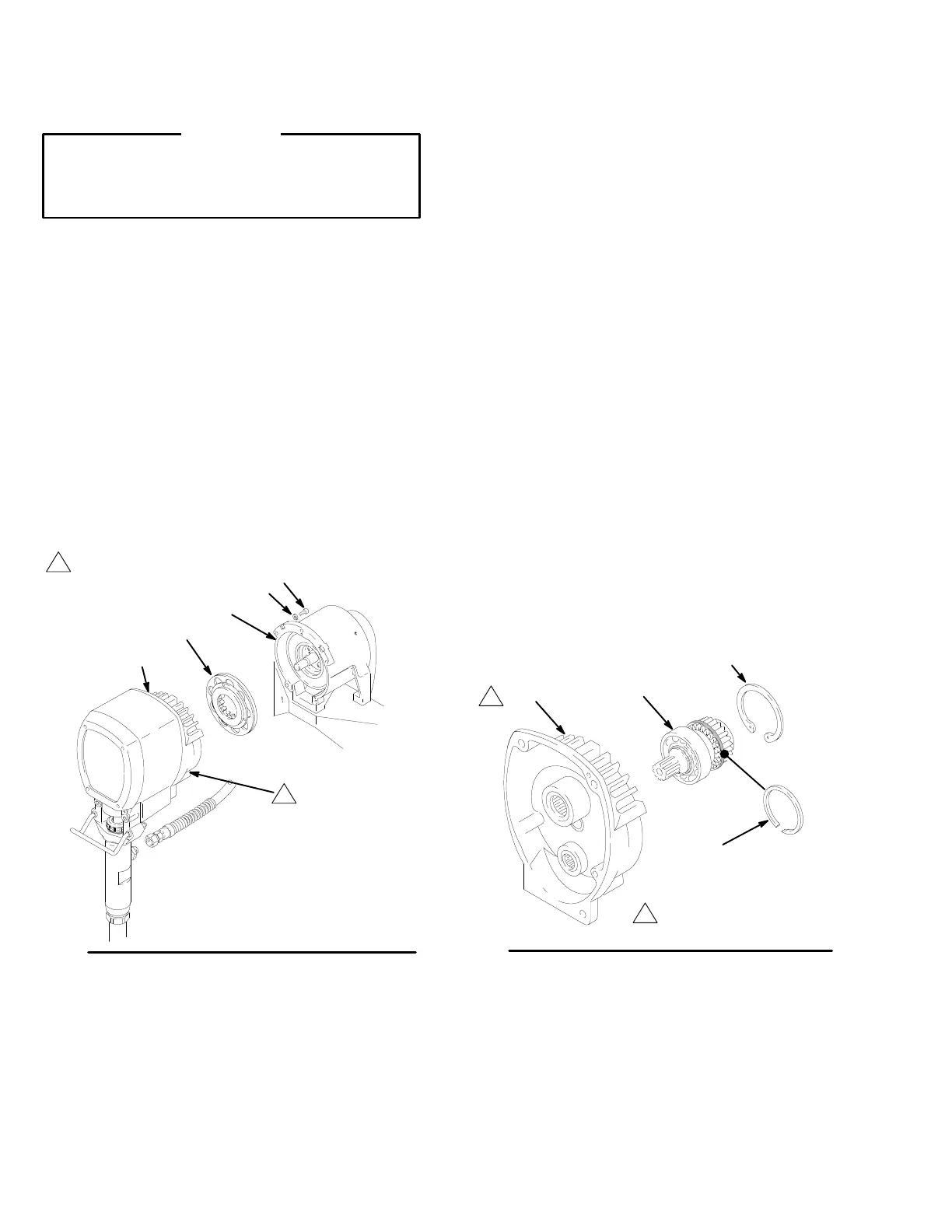

Repairing the Pinion

NOTE:

Repair Kit No. 236–394

includes the shaft and

bearings pre-assembled and lubricated. A hydraulic

press is not required. Use the repair procedure below

.

NOTE: If purchasing the pinion parts separately,

the repair must be done by a qualified technician since

parts must be press fit. Refer to the parts drawing on

page 38.

NOTE:

Refer to Fig. 9 except where noted.

1.

Remove the retaining ring (218e).

2.

Remove the large ring (217) from the bearing re

-

cess of the pinion housing (219).

3.

Pull the the pinion output shaft (218) out of the

housing (219).

4.

Install the new pinion output shaft (218) into the

pinion housing, pushing it to the shoulder of the

housing (219).

5.

Install the rings (218e and 217).

6.

Go to

Reassembly

, page 24, Steps 3 and 4, or

continue on page 21.

Fig. 9

219

218

217

02787

Drive

housing shown

removed for visual

purposes only

218e

Loading...

Loading...