10

308-327

Setup

WARNING

If

you are supplying your own hoses and spray

gun, be sure the hoses are electrically conductive,

that the gun has a tip guard, and that each part is

rated for at least

3000 psi (210 bar) Maximum

Working Pressure

. This is to reduce the risk of seri

-

ous injury caused by static sparking, fluid injection

or over-pressurization and rupture of the hose or

gun.

CAUTION

T

o avoid damaging the pressure control, which may

result in poor equipment performance and compo

-

nent damage, follow these precautions.

1.

Always use nylon spray hose at least 50 ft.

(15.2 m) long.

2.

Never use a wire braid hose; it is too rigid to

act as a pulsation dampener

.

3.

Never install any shutof

f device between the

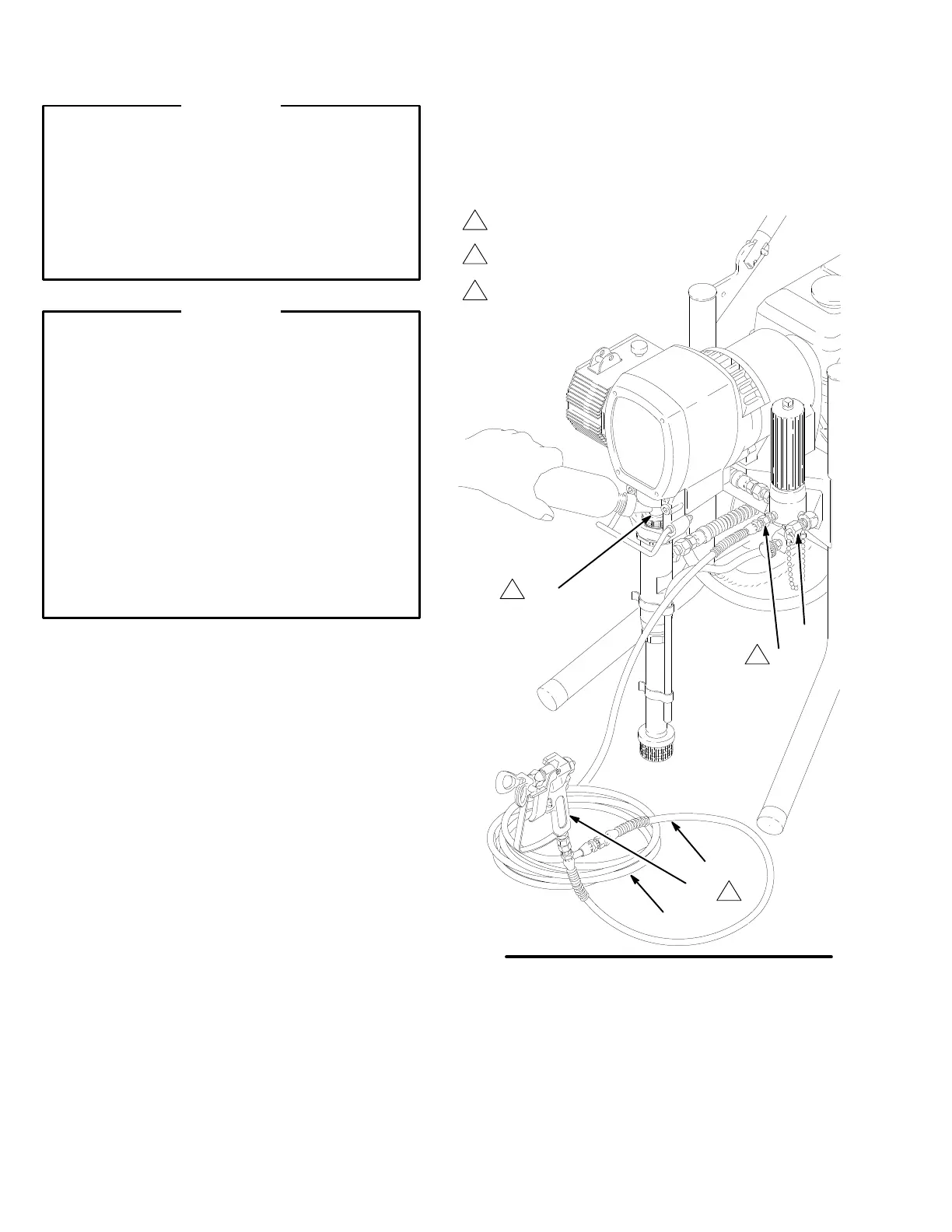

filter and the main hose. See Fig 1.

4.

Always use the main filter outlet (55) for one

gun operation. Never plug this outlet.

1.

Be sure your system is properly grounded.

Read and follow the warning section, FIRE OR

EXPLOSION HAZARD, on page 5. If you are

using the sprayer with the gasoline engine, secure

the ground wire to a true earth ground. If you are

using the sprayer with an electric motor

, plug it into

a properly grounded outlet.

2. Connect the hose and gun.

Screw the 50 ft.

(15.2 m) main fluid hose (126) onto the outlet

nipple (55). Screw on the whip end hose (127).

Screw on the gun (128). Do not use thread sealant

on swivels, and do not install the spray tip yet! See

Fig. 1.

3. Two gun hookup.

Remove the cap (56) from the

secondary hose outlet and attach an accessory

hose and gun to the 1/4 npsm(m) nipple.

See Fig. 1.

4. Fill the packing nut/wetcup (416).

One full squirt

of Graco Throat Seal Liquid (TSL) is usually

enough.

Do

not install any shutof

f

device here.

Fill with TSL

Fig.

1

02688

Do

not use thread sealant

on swivels

55

56

126

128

127

416

Loading...

Loading...