Pressure

Control Adjustment

WARNING

USE

EXTREME CAUTION WHEN PERFORMING

THIS CALIBRA

TION PROCEDURE

to reduce the

risk of a fluid injection injury or other serious bodily

injury

, which can result from component rupture,

electric shock, fire, explosion or moving parts.

This procedure sets the sprayer to 2600–3000 psi

(182–210 bar) MAXIMUM WORKING PRESSURE.

This procedure must be performed whenever the

pressure control assembly is removed and rein

-

stalled, or replaced, to be sure the sprayer is

properly calibrated.

Improper calibration can cause the sprayer to

over–pressurize and result in component rupture, fire

or explosion. It may also prevent the sprayer from

obtaining the maximum working pressure,

resulting in poor sprayer performance.

NEVER attempt to increase the fluid outlet pressure

by performing these calibrations in any other way

.

NEVER EXCEED 3000 psi (210 bar) MAXIMUM

WORKING PRESSURE. Normal operation of the

sprayer at higher pressures could result in compo

-

nent rupture, fire or explosion.

ALWA

YS use a

new

50 foot (15.2 m) spray hose,

rated for at least 3000 psi (210 bar) MAXIMUM

WORKING PRESSURE, when performing this

procedure. A used, under–rated hose could

develop a high pressure leak or rupture.

A

VOID touching the wires in the pressure control as

-

sembly when the control box cover is removed, to

reduce the risk of electric shock.

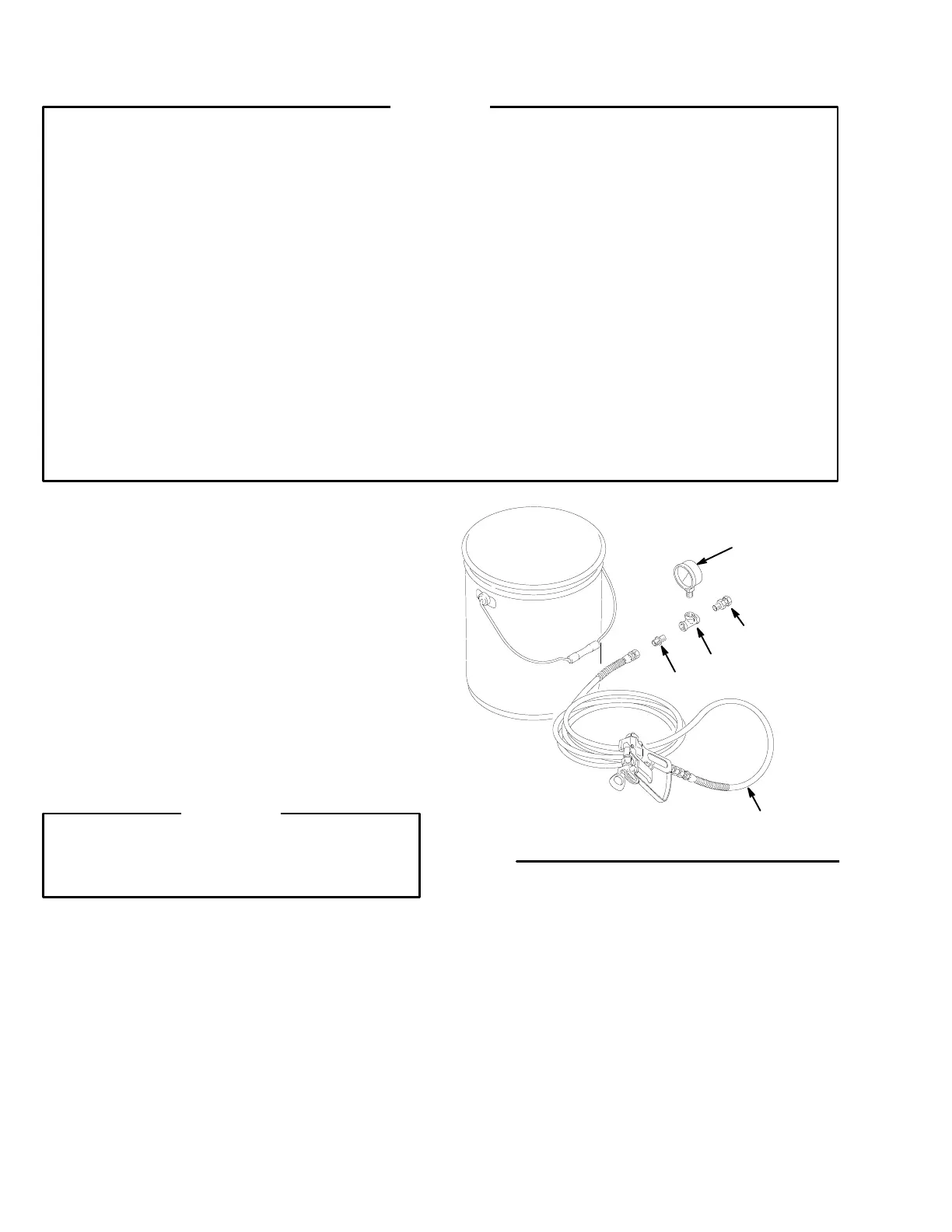

Service Tools Needed:

NEW

50 foot (15.2 m), 3000 psi (210 bar), flexible

nylon, airless spray hose, p/n 223–541

0–5000 psi (0–350 bar) fluid-filled pressure gauge,

p/n 102–814

NEW

spray tip, size 0.025 to 0.029

3/8 in. ignition wrench or nut driver

5 gallon pail and water or mineral spirits

Swivel, p/n 156–823

Nipple, p/n 162–453

T

ee, p/n 104–984

Set Up

WARNING

To

reduce the risk of serious injury

, always follow

the

Pressure Relief Procedure W

arning

on page

16 before repairing the sprayer

.

1.

Relieve pressure.

2.

Remove the original spray hose. Assemble and

install the components shown in Fig. 23 to the fluid

filter outlet.

Fig. 23

01201

102–814

156–823

104–984

162–453

223–541

Loading...

Loading...