Maintenance

22 3A1177B

Maintenance

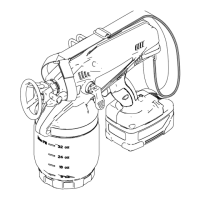

Caring for Sprayer

• Clean sprayer and accessories thoroughly after

each use.

• Do not cover vent holes or shroud while spraying.

Gun Fluid Filter

Clean gun fluid filter with compatible solvent and brush

every time you flush system. Replace when damaged.

Paint Hoses

Check hose for damage every time you spray. Do not

attempt to clean or repair hose if hose jacket or fittings

are damaged. Do not use hoses shorter than 7.5 m

(25 ft).

Tips

• Always clean tips with compatible solvent and brush

after spraying.

• Tip life: 57 liters (15 gallons) - 227 liters (60 gal-

lons)*

• Do not spray with worn tip.

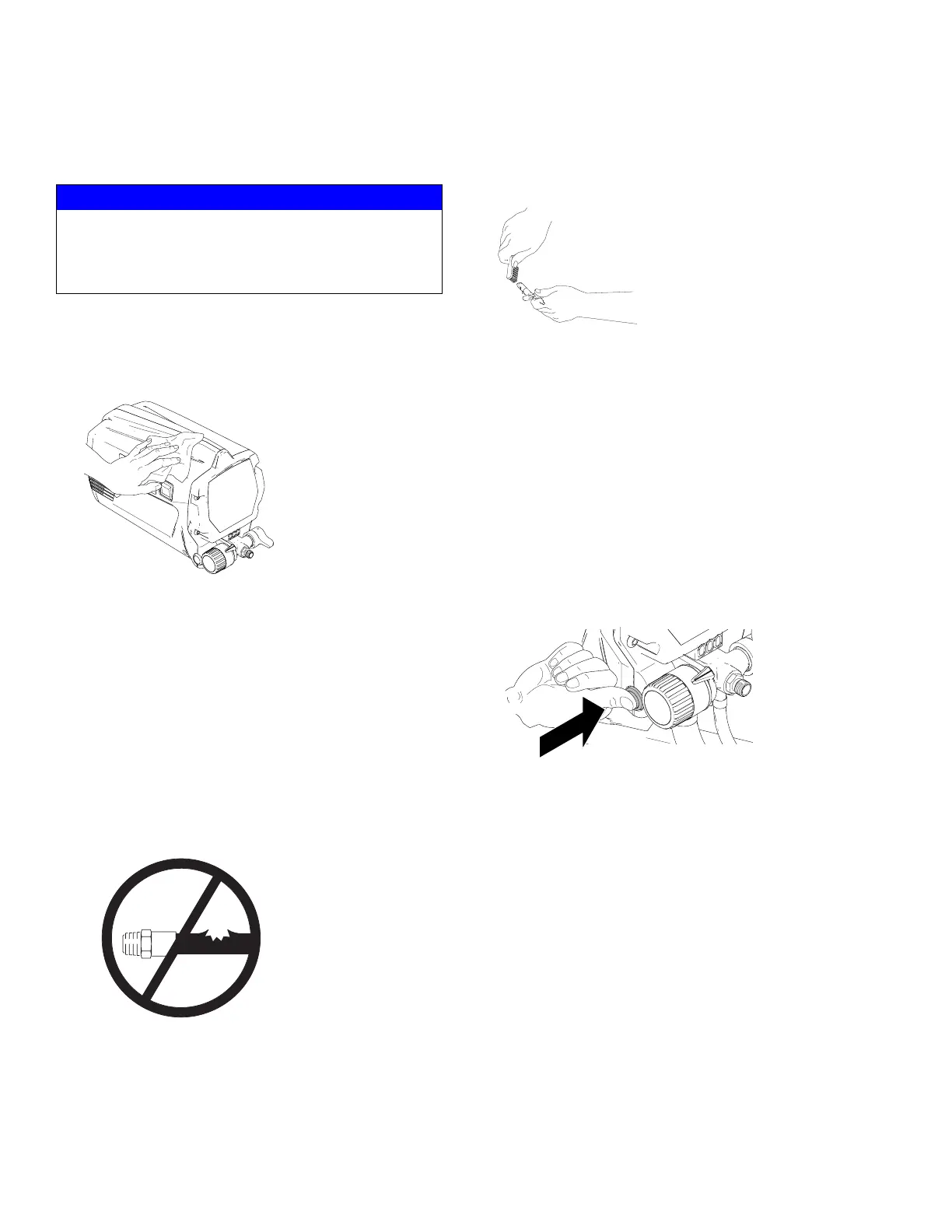

Pump Check Valves

• Storing in water, inadequate flushing or ingested

debris can cause either of the two check valves to

malfunction.

• If pump does not prime after 30 seconds, try to

loosen check balls by pushing pump priming button

or by tapping the inlet valve with a small wrench as

the sprayer is stroking.

NOTE: Excessive shock will fracture or cause other

damage to pump.

NOTE: To verify inlet valve ball is sticking, unscrew

valves from pump and check them.

If sprayer continues to cycle (motor and pump run)

after you release gun trigger, pump valves may be

obstructed or worn. Valve repair kits are available

from Graco/M

AGNUM authorized service centers.

Pump

When pump wears, paint will begin to leak down outside

of pump. Replace pump at first sign of leaking or addi-

tional damage could occur.

Pump repair kits are available from Graco/M

AGNUM

authorized service centers.

NOTICE

Openings in shroud provide air for cooling mechanical

parts and electronics inside. If water gets in these

openings sprayer could malfunction or be permanently

damaged.

ti15970a

ti15972a

Loading...

Loading...