Setup

20 3A2776K

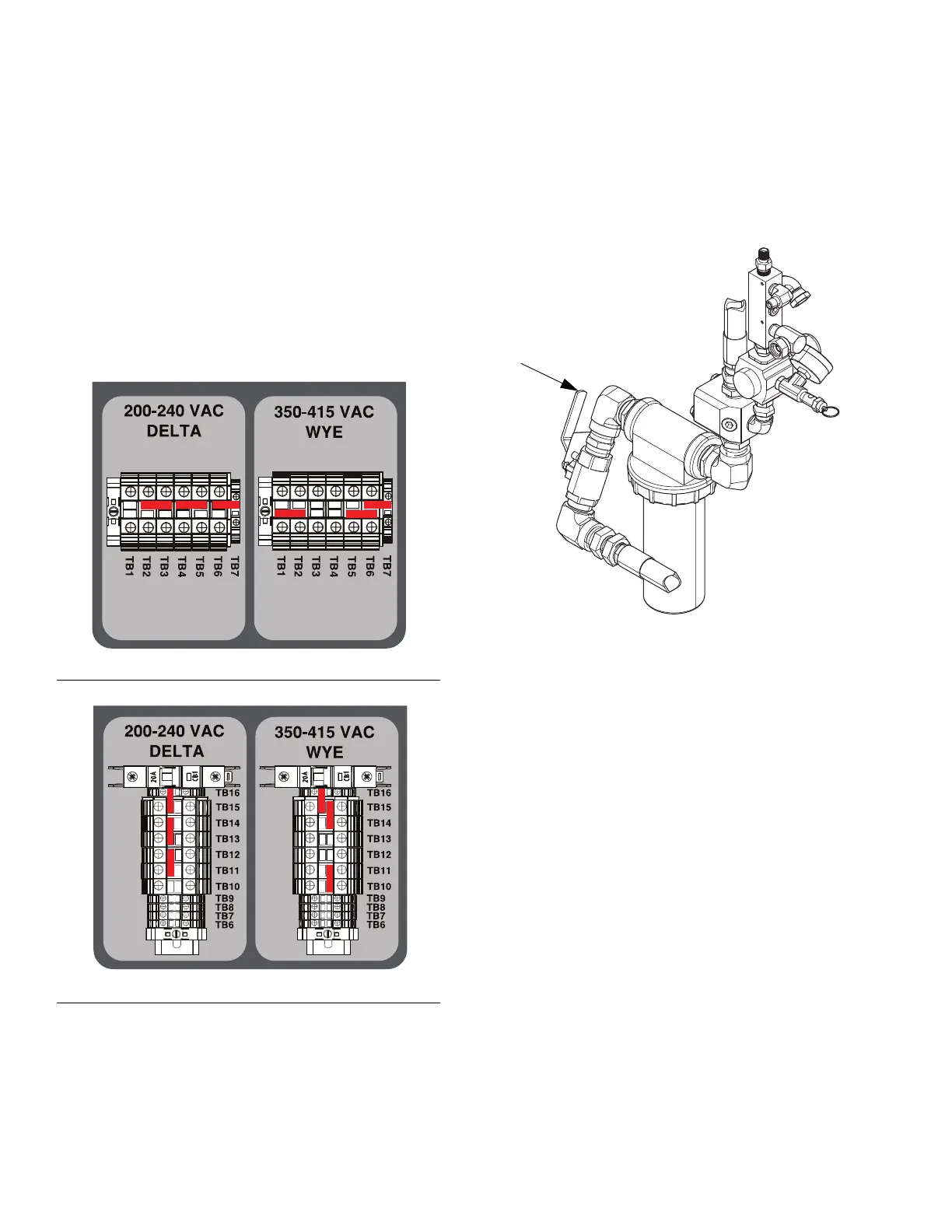

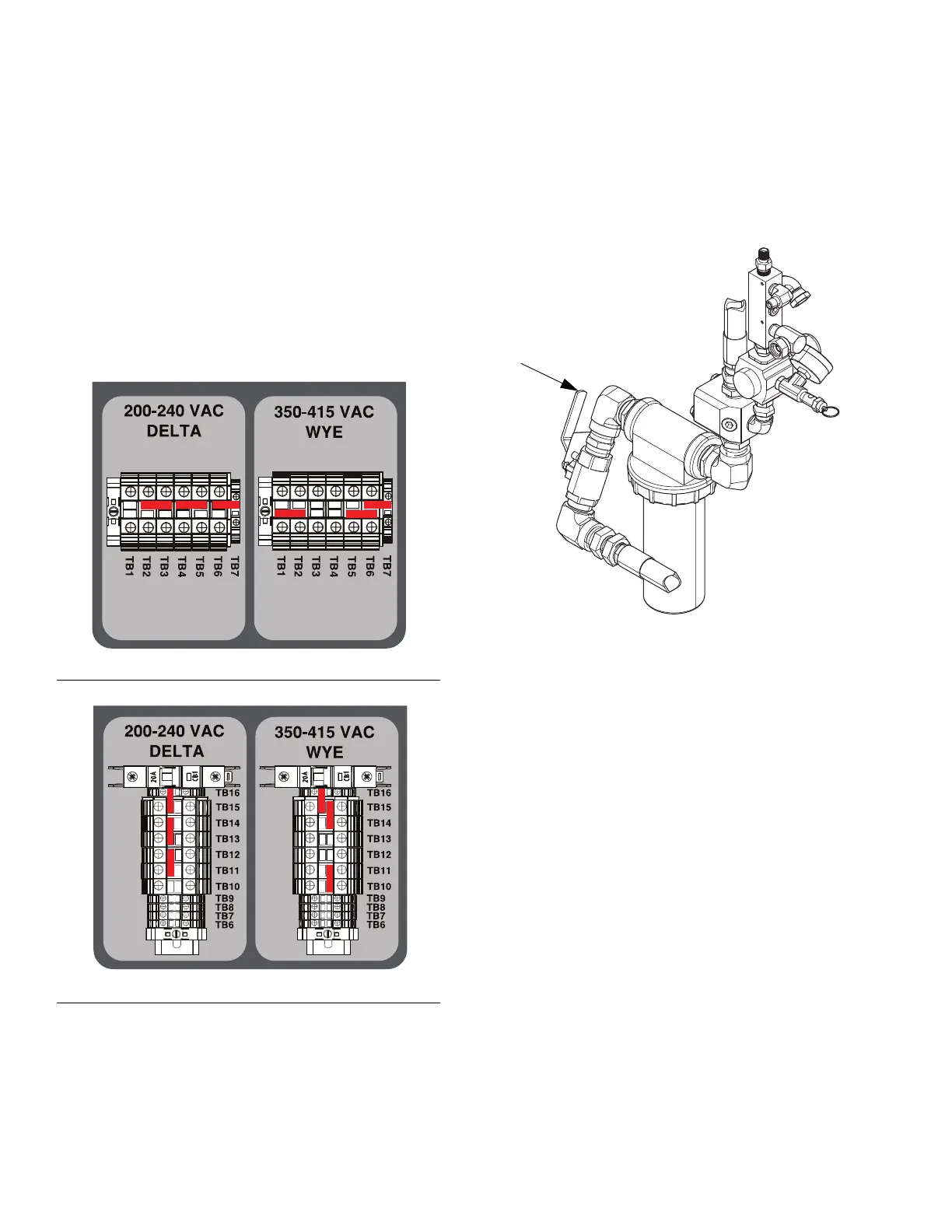

Set Power Jumpers

1. Find the red power jumpers for the terminal blocks

supplied in a plastic bag in the circuit box. For

hazardous location models, are in the explosion

proof box (E1).

2. For 200-240 VAC and 350-415 VAC, 3 Phase

installations only, use pliers to install the three red

power jumpers into the terminal blocks in the correct

positions as shown in the following illustration. Push

jumpers firmly into position.

3. Close junction box cover.

Connect Air Supply

Connect air supply line to the 1 in. npt(f) air supply ball

valve inlet.

Use a 3/4 in. (19.1 mm) ID minimum air hose.

Air supply requirement: 150 psi (1.0 MPa, 10.3 bar)

maximum; 80 psi (552 kPa, 5.5 bar) minimum (while

running).

Flow volume required: 100 scfm (2.8 m

3

/min) minimum;

250 scfm (7.1 m

3

/min) maximum. Available fluid

pressure and flow rate are directly related to available

air volume. A typical single gun XM PFP application will

use 125 to 175 scfm (3.5 to 5.0 m

3

/min).

Dosing valves are operated by air. The sprayer will not

operate correctly if the inlet air pressure drops below

80 psi (552 kPa, 5.5 bar) while spraying.

FIG. 12: Non-Hazardous Location Models

FIG. 13: Hazardous Location Models

Loading...

Loading...