Spray

3A2776K 43

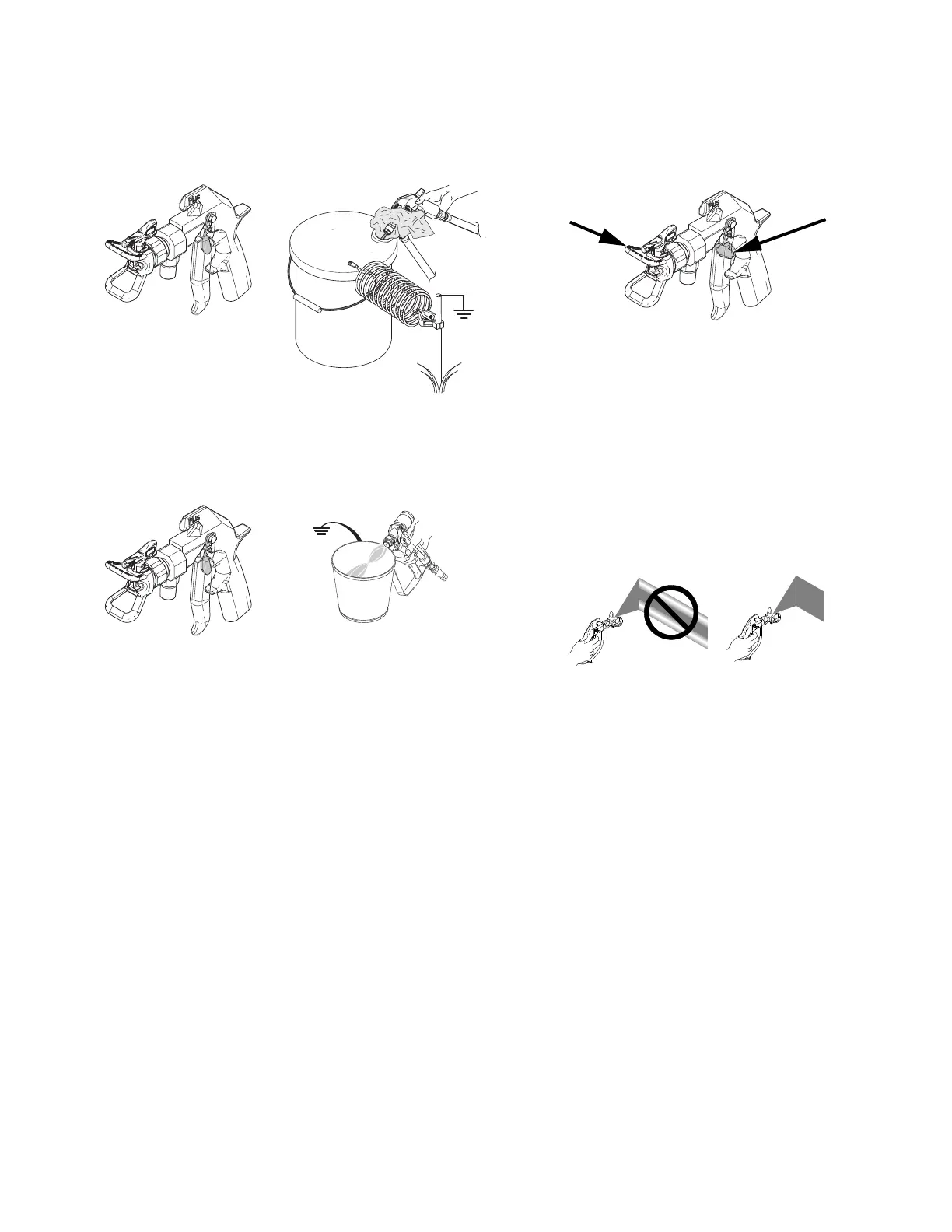

28. Disengage trigger lock and trigger gun into a

grounded metal pail. Use a metal pail lid with a hole

to dispense through to avoid splashing.

29. Adjust metering pump air regulator (CD) to 30 psi

(0.21 MPa, 2.1 bar).

30. Dispense until clean, well-mixed epoxy flows from

the gun.

31. Engage trigger lock.

32. Perform the Mix and Integration Tests on page 53.

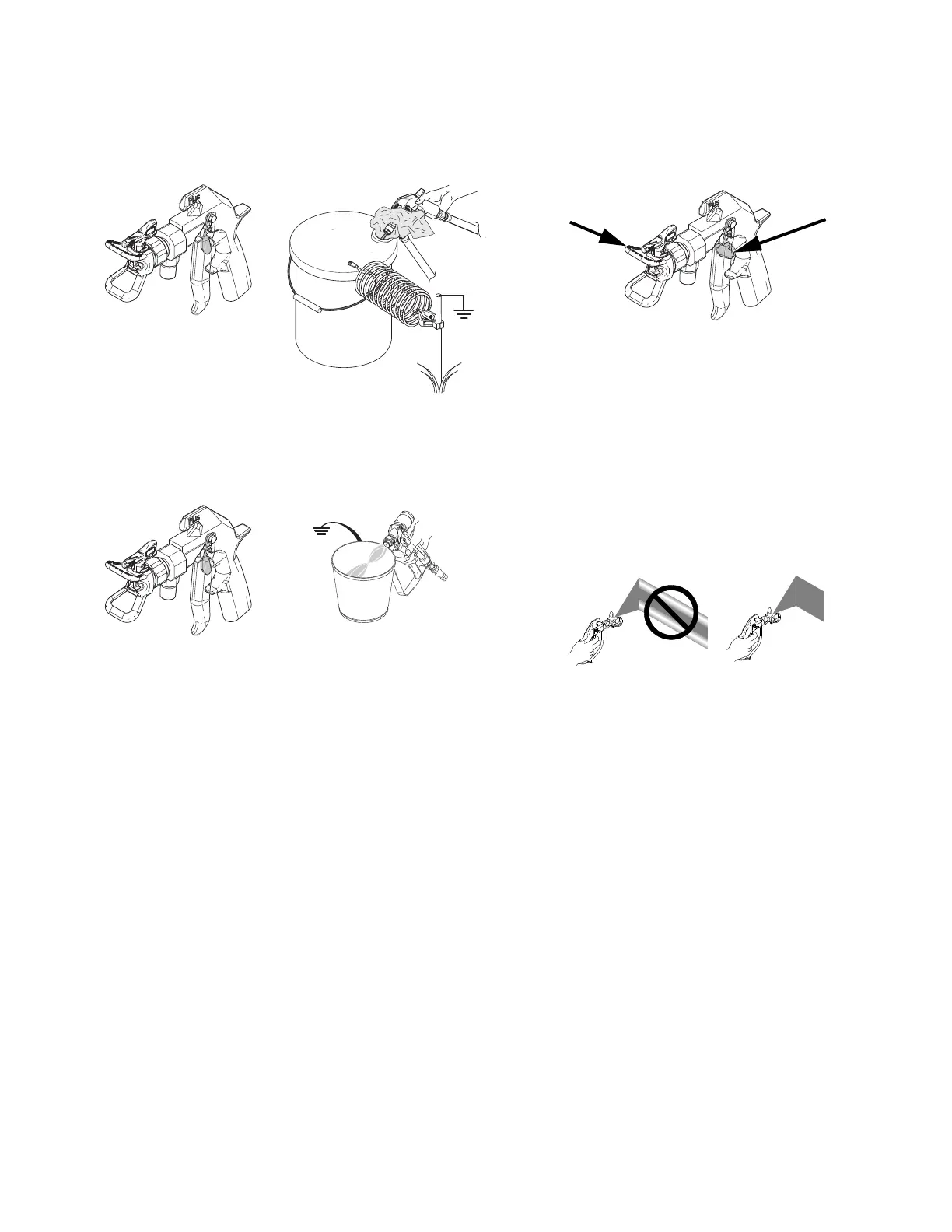

When necessary, engage trigger lock (1) then install

the tip (2) on gun.

NOTE: While spraying, it is best to continuously hold the

trigger. Do not release the trigger unless necessary.

This maximizes the material temperature consistency

and minimizes fiber buildup.

33. Adjust metering pump air regulator (CD) to the

necessary spraying pressure and trigger gun to

spray material on a test panel. Look at ratio screen

to ensure it is reading the correct ratio. Continue

spraying on the test panel until the desired pattern

results then begin spraying the production surface.

34. Follow Flush Mixed Material on page 44 when you

are finished spraying if the potlife of the mixed

materials in the system could expire before you

spray again.

NOTE: Pot life of the mixed materials in the system is

much shorter than the dry time of dispensed epoxy

because mixed material potlife or working time

decreases with increased temperature.

Loading...

Loading...