Pressure Relief Procedure

3A2776K 47

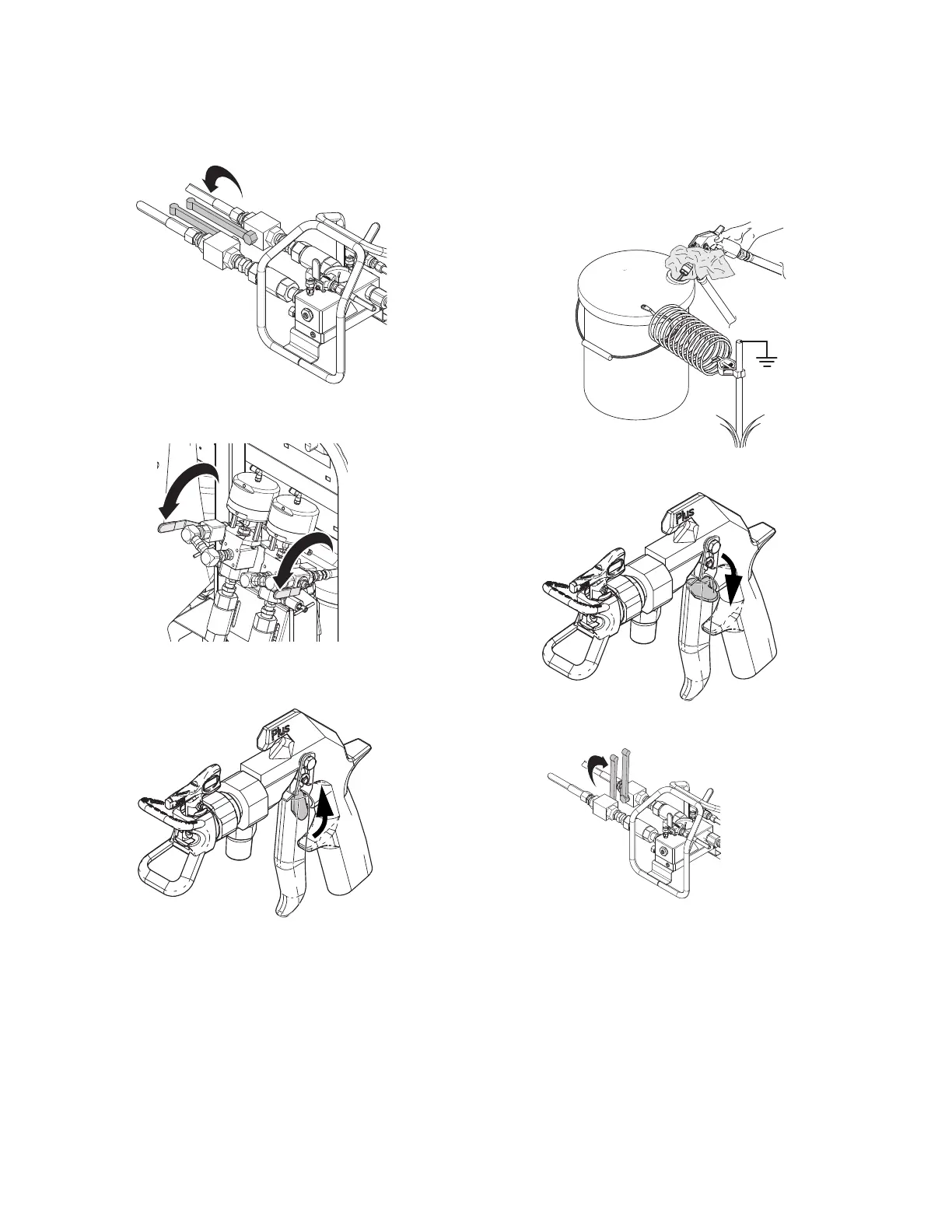

6. Open mix manifold ball valves.

7. Open recirculation ball valves.

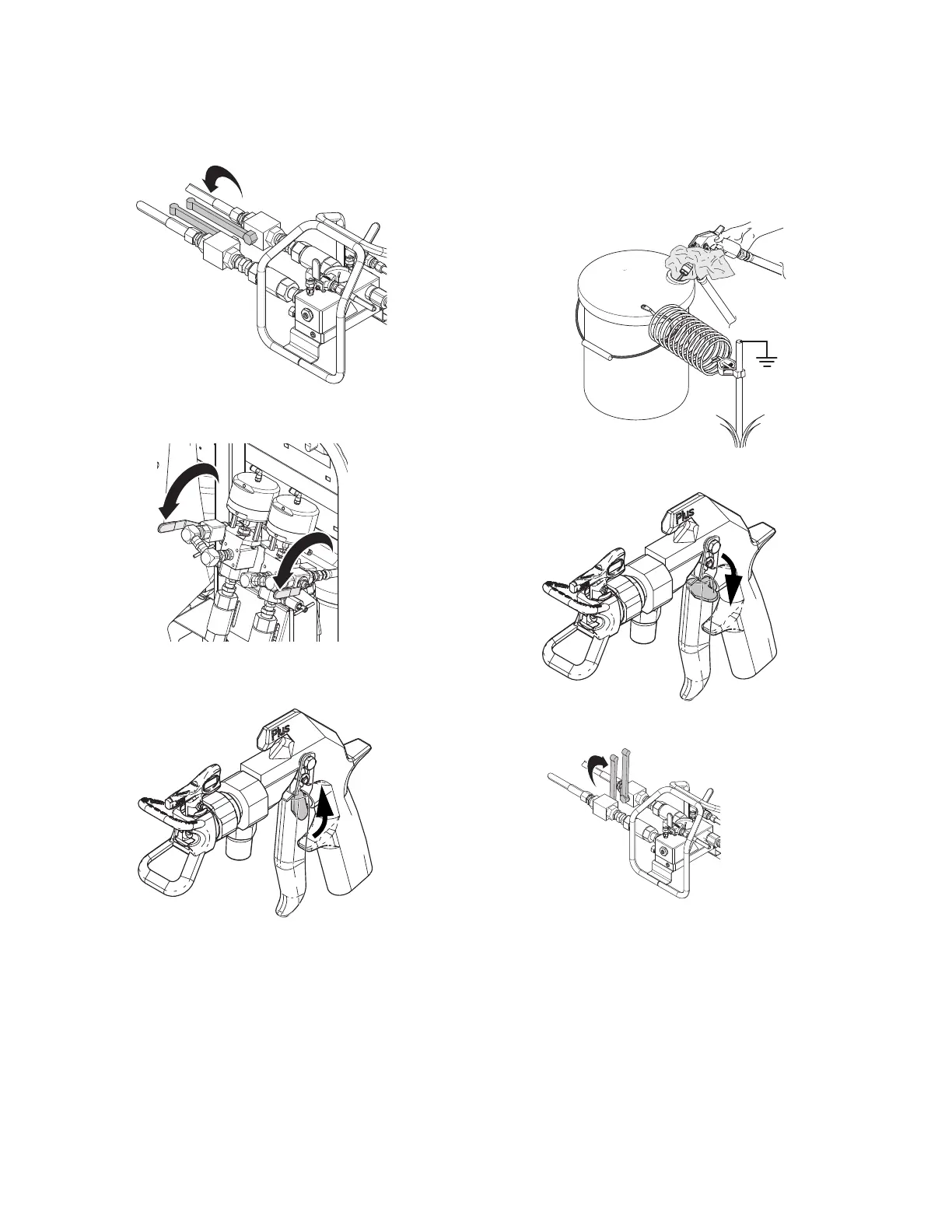

8. Disengage trigger lock.

9. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure in

material hoses. Use a pail lid with a hole to dispense

through. Seal around hole and gun with a rag to

prevent splash back.

10. Engage trigger lock.

11. Close mix manifold material ball valves.

12. Perform Flush Mixed Material procedure beginning

on page 44 to prevent mixed material curing in the

system and to relieve pressure in the flush lines.

13. If the system will be shutdown for more than a few

hours, fill metering pump A and B packing nuts with

throat seal liquid (TSL).

NOTE: Fluid pressure in the system is now relieved.

WLLD

WLD

Loading...

Loading...